Why Speed Matters in CNC Prototyping?

In the high-stakes world of product development, the difference between a market leader and a follower often comes down to speed. Rapid CNC Prototyping isn’t just about getting a part quickly; it’s about maintaining the momentum of your entire project.

When your team is facing critical milestones, every hour counts:

Product Validation: Quickly testing form, fit, and function to avoid costly downstream errors.

Investor Presentations: Having a high-quality, physical model to secure funding.

Emergency Project Deadlines: Solving unexpected engineering failures before they stall production.

Engineering Modifications: Iterating on a design change and seeing the physical result by the end of the week.

The Shift to “3-Day CNC Prototypes”

A “3-day CNC prototype” was once a luxury, but today it is a standard for top-tier CNC prototype manufacturers like Samshion. This is made possible by the convergence of high-speed machining centers, rapid quoting systems, and advanced CAM software.

Ordinary CNC Suppliers vs. Rapid Prototyping Specialists The primary difference lies in the workflow. Traditional CNC machining services are often optimized for high-volume production, where setup time is spread across thousands of parts. In contrast, Rapid Manufacturing specialists optimize for “Setup One.” By utilizing dedicated prototype cells and an engineering-first mindset, they can bypass the typical 2-week lead time found in generic machine shops.

Day 0: Engineering Review & DFM Optimization

The countdown to a 3-day delivery doesn’t start when the machine spindle begins to spin; it starts the moment you submit your data. According to Benny Xu, Technical Director at Samshion, many factories tend to overlook the critical importance of “Day 0.” “Day 0” is dedicated to transforming your 3D CAD files into a flawless manufacturing roadmap.

Instant RFQ & File Review

In rapid manufacturing, every hour spent waiting for a price is an hour lost in production. To keep your project on track, we’ve streamlined the intake process:

Supported Formats: We work directly with STEP, IGES, and STL files, ensuring no data is lost during translation.

Same-Day Quotation: Our engineering team prioritizes incoming requests, providing detailed quotes within hours, not days. This allow you to hit “Go” while your design logic is still fresh.

DFM Analysis Before Programming

Design for Manufacturing (DFM) is the secret weapon of Samshion Rapid. Before a single line of G-code is written, our engineers perform a comprehensive audit of your part’s geometry:

Tolerance Validation: We ensure that your specified tolerances are achievable within the rapid timeline. If a tolerance is unnecessarily tight, we’ll flag it to save you time and cost.

Fillet & Corner Optimization: Sharp internal corners require slow EDM or specialized tooling. We suggest radius adjustments that allow high-speed end mills to clear material faster.

Tool Accessibility Check: We verify that standard tools can reach every pocket and feature, reducing the need for custom, time-consuming jigs.

Material Machinability Review: Whether it’s Aluminum 6061 or a high-performance plastic like PEEK, we confirm the material’s behavior under high-speed cutting to prevent warping or tool breakage.

Why DFM Before CNC Programming Saves Hours

Most delays in CNC machining services happen when a programmer realizes mid-way that a part cannot be clamped or a deep hole cannot be reached. By performing a rigorous DFM review first, Samshion Rapid eliminates these “stop-work” orders.

This proactive step ensures that when your file reaches the CNC programming stage, it is already “optimized for speed,” allowing the CAM team to work straight through without hitting technical roadblocks.

Day 1: CNC Programming & Process Planning

Once the design is optimized, the focus shifts to the “brain” of the operation. This is where CNC Programming determines how efficiently the machine moves. Samshion doesn’t just program to cut; we program to win back time.

CAM Programming Starts Immediately

Our expert CAM (Computer-Aided Manufacturing) engineers begin Toolpath Generation the moment DFM is approved. Roughing vs. Finishing is carefully defined: we use high-efficiency roughing strategies to remove bulk material at maximum speed, followed by precision finishing passes to meet your exact surface requirements.

At the same time, Multi-axis vs. 3-axis Strategy Selection is evaluated. Our team decides whether to utilize 3-axis, 4-axis, or full 5-axis machining. By choosing 5-axis for complex geometries, we can often machine five sides of a part in one go, saving hours of manual labor. Machining Sequence Planning is also finalized, with the order of operations meticulously planned to ensure structural integrity and minimize tool changes.

Fixture & Setup Strategy

Setup time is often where traditional shops lose the most time. To hit a 3-day window, Samshion Rapid employs advanced work-holding tactics. We use Soft Jaws & Quick Fixtures, including pre-machined soft jaws and modular fixtures that allow for near-instant part alignment and secure clamping.

Reducing Setup Changes is a key principle. Every time a human has to touch a part to flip it, the clock stops, so we prioritize strategies that minimize “flips.” Programming for One-Clamping Machining is applied whenever possible, allowing the part to be finished in a single clamping. This not only saves time but also guarantees superior geometric accuracy between features.

Simulation & Collision Check

Speed is useless if the machine crashes. Before the code ever reaches the shop floor, it undergoes a rigorous digital dry run. Full Toolpath Simulation is performed using a virtual twin of the machining process to ensure every movement is efficient and accurate. Tool & Holder Interference Check confirms that the cutting tool, tool holder, and machine spindle have clear paths, preventing costly damage and delays. Finally, Cycle Time Optimization is carried out by analyzing the simulation, shaving seconds—or even minutes—off each operation to ensure your CNC prototypes are finished as fast as physics allow.

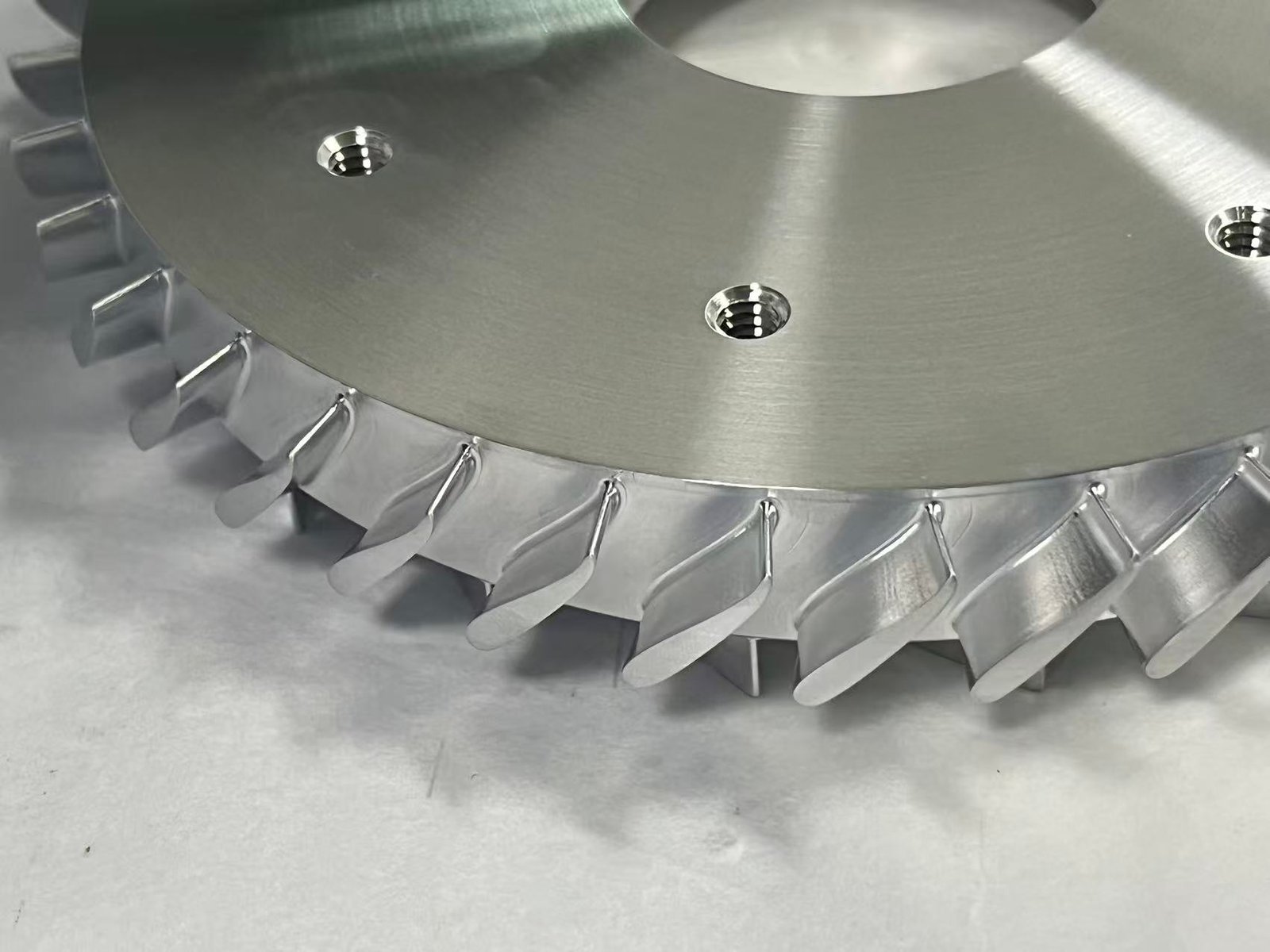

Day 2: High-Speed CNC Machining

By the second day, the groundwork is laid. The code is verified, the strategy is set, and the focus moves to the shop floor. This is where Samshion Rapid leverages industrial-grade power to turn raw blocks into precision CNC prototypes.

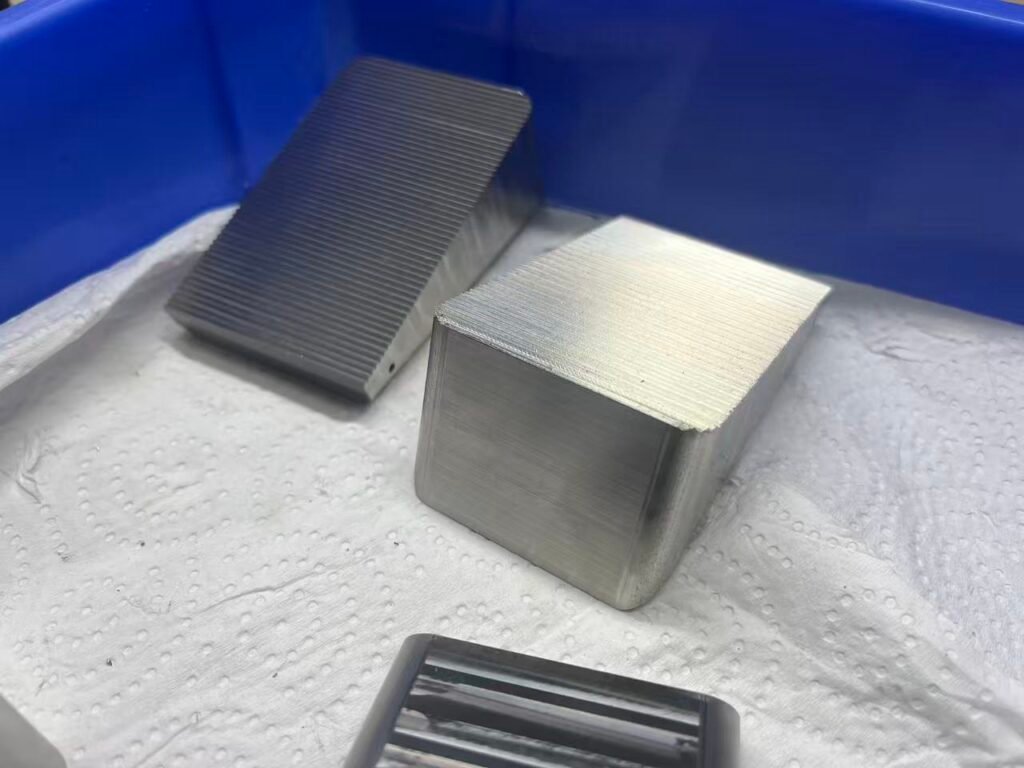

Material Preparation & Machine Allocation

Time is the enemy of rapid manufacturing. To ensure no delays, we maintain some in-house stock of the most common engineering materials. This allows us to move from programming to cutting in minutes.

In-stock materials include:

Aluminum (6061 / 7075):

The gold standard for rapid prototyping due to its excellent machinability and strength-to-weight ratio.

Stainless Steel (303 / 304 / 316L):

For prototypes requiring high corrosion resistance or medical-grade durability.

Brass & Copper:

Ideal for electrical components or decorative hardware.

High-Performance Plastics:

We stock POM (Delrin) for low friction, Nylon for toughness, and PEEK for high-temperature applications.

Lights-Out / Priority Machining

Generic machine shops often get “clogged” by large production runs, pushing small prototype jobs to the back of the line. We operate differently by dedicating specific resources to urgent work.

Dedicated Prototype Machines:

We reserve high-precision Haas CNC centers exclusively for rapid-turnaround projects. Your job never waits in a queue behind a 10,000-piece production run.

High-Speed Spindle Machining:

Our machines utilize high-RPM spindles (up to 20,000 RPM). This allows for faster material removal rates and superior surface finishes that require less manual post-processing.In-Process Probing:

To ensure “first-part-correct” quality, we use automated on-machine probes. These sensors verify the part’s position and dimensions in real-time, allowing the machine to self-correct and eliminate manual measurement delays.

Why Day 2 is the “Heart” of the Timeline

By combining a ready material inventory with high-speed spindles, Samshion Rapid can complete the bulk of the metal removal within a single 24-hour window, leaving the final day for the finishing touches.

Day 3: Finishing, Inspection & Shipping

On the final day, your part transitions from a raw machined component to a finished product. At Samshion Rapid, the goal is to balance aesthetic quality with the speed required to hit your 72-hour deadline.

Post-Processing Options

Even on a “Rapid” timeline, a prototype shouldn’t look unfinished. We offer several in-house “fast-track” finishes:

Deburring: Every part is manually or vibratory deburred to ensure clean edges and safe handling.

Sandblasting: We apply a uniform matte finish to remove tool marks and prepare the surface for branding or coating.

Anodizing (Prototype-grade): For aluminum parts, we offer rapid clear or color anodizing to provide surface hardness and corrosion resistance.

Laser Marking: We can laser-etch part numbers, logos, or QR codes directly onto the surface for easy identification during your assembly phase.

Quality Inspection & Reporting

Speed is meaningless if the part doesn’t fit. Samshion’s team ensures every prototype meets your specifications before it leaves the building:

Critical Dimension Check: We focus on the “tight” tolerances that matter most to your assembly’s functionality.

CMM / Caliper Inspection: Using high-precision Coordinate Measuring Machines (CMM) and digital calipers, we verify geometric accuracy.

Inspection Report on Request: We provide full measurement data so your engineering team can trust the part the moment it arrives.

Express Packaging & Global Shipping

The final hours are about logistics. We don’t let a part sit on a shelf.

DHL / FedEx / UPS: We utilize premium express accounts to ensure the fastest possible transit times.

Same-Day Pickup: Once the inspection is signed off, the parts are packed in protective custom foam and handed to the courier for same-day dispatch.

Why Programming Speed Is the Key to 3-Day CNC Prototypes

Many customers believe the “machining” takes the longest. In reality, the machine usually runs for only a few hours. The true secret to Samshion Rapid’s speed lies in the digital preparation.

Programming Bottlenecks vs. Machining Time

In traditional shops, a project might sit in a “programming queue” for three days before a machine is even turned on. We eliminate this bottleneck by starting the CAM process within minutes of order confirmation.

Experienced CAM Engineers vs. Generic Workshops

Generic workshops often have one person doing everything. At Samshion Rapid, our dedicated CAM engineers are specialists in Rapid Manufacturing. They know how to write code that prioritizes speed without sacrificing tool life or part accuracy.

Standardized Post-Process & Tool Libraries

We don’t reinvent the wheel for every project. We maintain standardized tool libraries across all our machines. This means:

The programmer knows exactly which tools are already in the machine.

The “Post-Processor” (the software that translates CAM to machine code) is perfectly tuned to our specific CNC centers. This eliminates the “trial and error” phase on the shop floor, allowing the first part to be the right part.

Common Mistakes That Delay CNC Prototypes

Samshion’s CEO Reid once pointed out that despite our utmost caution, certain design and communication errors can still cause delays. Avoiding these common pitfalls will ensure your CNC machining services stay on track.

1. No DFM Before Programming

As mentioned in Day 0, jumping straight into programming without a Design for Manufacturing review is a recipe for disaster. If a feature is unmachinable (like a square internal corner that a round drill cannot cut), the programmer must stop, call the client, and wait for a redesign. This can waste half a day of production time.

2. Over-Tight Tolerances

Requesting a ±0.005 mm tolerance when ±0.05 mm would suffice for a fit-check model significantly slows down the process. Ultra-tight tolerances require slower machine speeds, specialized measuring tools, and constant temperature monitoring. Only apply high precision where it is functionally necessary.

3. Unclear Surface Finish Requirements

Notes like “smooth finish” or “look good” are subjective and lead to delays. To keep things moving, use industry-standard callouts like Ra 1.6 or specify “As-machined with deburring.” This allows Samshion Rapid to select the correct tooling and speeds immediately.

4. Late Design Changes

Once the CNC programming is finished and the material is clamped on the machine, any change to the CAD file essentially resets the project to Day 0. To hit a 3-day window, ensure your design is “frozen” before the quote is approved.

Why Choose a Rapid CNC Prototyping Partner

When your project is on the line, the partner you choose determines whether you meet your deadline or face a costly delay. A specialized CNC prototype manufacturer like Samshion Rapid operates with a completely different DNA than a traditional machine shop.

In-House Programming Team

Many shops outsource their programming or have a single person handling both setup and CAM. At Samshion Rapid, our dedicated in-house programming team works alongside our machinists. This real-time collaboration allows us to solve technical hurdles in minutes, not days, ensuring the CNC programming phase is completed at lightning speed.

Prototype-Dedicated Machines

In a standard machine shop, a small prototype order is often “filler” for when their big production runs finish. At a rapid prototyping specialist, the machines are reserved exclusively for short-run, high-speed projects. Your parts have a “VIP pass” to the spindle—they never wait in line behind a 5,000-piece production order.

Engineering-First Mindset

We don’t just “cut to print.” Our team approaches every project with an engineering lens. By reviewing your CNC prototypes for functional integrity and machinability during the DFM phase, we act as an extension of your R&D team. This mindset prevents the “garbage in, garbage out” cycle that often occurs with generic vendors.

Experience with Urgent Projects

A 3-day turnaround is high-pressure. It requires a logistics chain, a shift schedule, and a quality control process that are all tuned for speed. Samshion Rapid has built its reputation on these “mission-critical” projects. We understand the stakes of an upcoming board meeting or a looming product launch, and our entire workflow is built to handle that urgency without sacrificing precision.

Conclusion

A 3-day CNC prototype is not the result of magic—it is the result of a highly disciplined, process-driven manufacturing engine. The real speed in Rapid Manufacturing doesn’t come from simply running machines faster; it comes from eliminating the “white space” and friction between steps.

By integrating rigorous DFM, lightning-fast CNC programming, and dedicated machine allocation, Samshion Rapid turns weeks of traditional waiting into just 72 hours of progress.

The real speed comes from:

DFM: Catching errors before they hit the shop floor.

Fast CNC Programming: Translating design into motion without delay.

Efficient Machining: Using high-speed strategies and dedicated spindles.

Controlled Quality: Ensuring the part is right the first time.