From complex prototypes to low-volume production, we deliver ISO 9001 certified parts in as fast as 3 days. Upload your CAD file today and get a quote within 6 hours.

Prototypes delivered in as fast as 24 hours. We understand your deadlines and scale with your project needs.

Strict adherence to ISO 9001 standards. Tolerances down to +/- 0.01mm for critical features.

From 1 single prototype to 10,000+ production parts, we handle orders of all sizes with equal care.

Your Partner in Precision and Speed

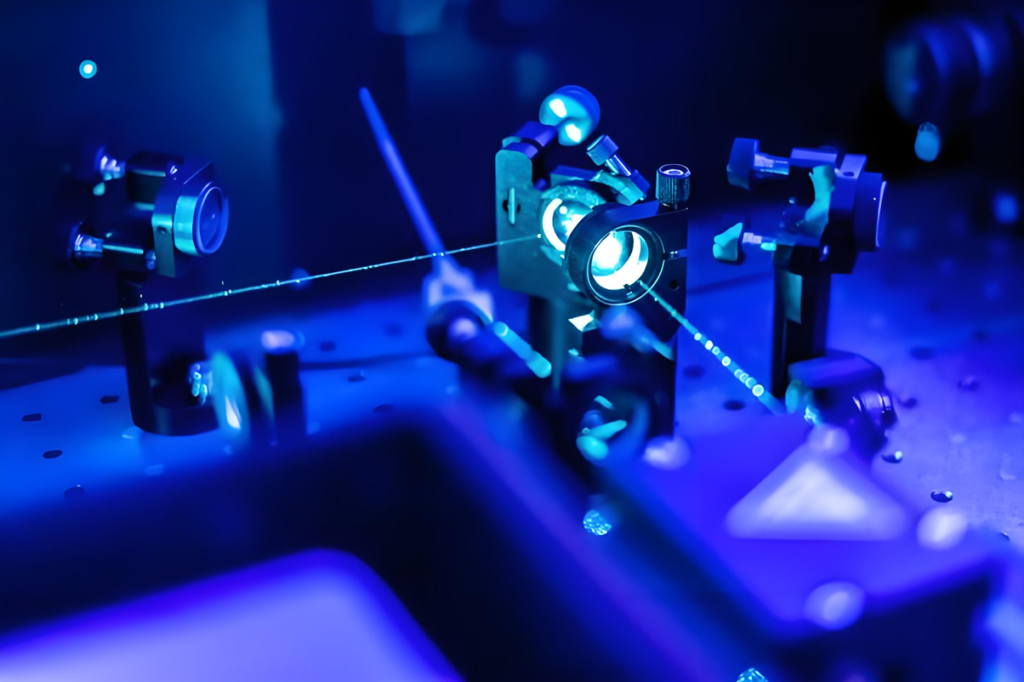

Samshion offers rapid prototyping services to turn your digital designs into fully functional prototypes with unmatched speed and accuracy. Our in-house capabilities include precision CNC machining, 3D printing, vacuum casting, sheet metal prototyping, and rapid tooling — all designed to support fast design validation and iterative development.

With expert engineering support and advanced technologies, we help you reduce lead times, test performance, and move confidently toward production.

From Prototypes to Market-Ready Products

Samshion provides scalable, cost-effective manufacturing solutions — bridging the gap between prototyping and full-scale production. Our services include production-grade CNC machining, plastic injection molding, die casting, sheet metal fabrication, and post-processing.

Whether you need small-batch production or mass manufacturing, we ensure high quality, fast turnaround, and seamless delivery. Our deep industry experience guarantees that every part meets your specific requirements and performance standards.

Samshion is your ISO 9001-certified partner for custom CNC machining and rapid prototyping services. From low-volume prototypes to high-volume manufacturing, we deliver mission-critical components with micron-level precision — trusted by innovators across automotive, aerospace, and medical industries.

Accelerate your product development with our complete rapid prototyping services — combining CNC machining, 3D printing, and vacuum casting.

We help engineers iterate faster and reduce lead times, bridging the gap from concept to production with unmatched precision.

We deliver high-precision CNC machining services using 3-, 4-, and 5-axis equipment for AL, stainless steel, and engineering plastics.

With ±0.005mm tolerances and consistent quality, we’re trusted by medical,aerospace and automotive industries.

Our plastic injection molding services cover both prototype tooling and mass production.

We offer DFM feedback, in-house mold making, and fast turnaround — ideal for scaling from rapid prototyping to final production.

We provide precision sheet metal fabrication for brackets, enclosures, and panels — using laser cutting, CNC bending, and welding.

From prototypes to scalable production, we deliver tight tolerances and fast lead times.

At Samshion, we uphold ISO 9001:2015-certified quality standards across our vertically integrated facilities. Our expert team combines precision CNC manufacturing with advanced 3D inspection systems to ensure every part meets exacting standards.

Every component is validated through:

Our experienced team and flexible workflows enable fast lead times — so your products get to market faster, without compromising quality.

Achieve up to 50% cost savings compared to US/EU suppliers. We offer free DFM optimization, reduce waste by 15%, and provide volume discounts of 10–20% on low-volume orders.

We’re more than a manufacturer – we’re your innovation partner. As a global leader in rapid prototyping and precision manufacturing, we bring ideas to life by merging cutting-edge technologies, ISO-certified quality standards, and an unwavering commitment to your success.

From Fortune 500 giants to breakthrough startups, industry leaders trust Samshion to turn concepts into reality – fast, reliably, and with absolute precision.

Our expertise spans CNC machining, 3D printing, and automated precision inspection.

Every component we deliver – from a one-off prototype to mass production – meets +0.005 mm tolerances, setting the benchmark for quality in aerospace, medical, and consumer applications.

When your vision demands excellence, Samshion delivers.

Start your project in minutes, backed by our 24/7 engineering team. No upfront cost | 2h response | 100% quality guaranteed

Submit your CAD files (STEP, IGES, X_T) and requirements. We accept SolidWorks, AutoCAD, STL, etc

Receive a detailed quote and Design-for-Manufacturability report within 24 hours.

Confirm PO, and production starts immediately. 100% compliant with your specifications.

Parts ship with full inspection reports (CMM data available).

At Samshion, quality isn’t a department — it’s a discipline.

Every material batch is verified using advanced spectroscopy, and every component is inspected with 3D scanning systems to ensure micrometer-level dimensional accuracy.

With a 99.2% first-article acceptance rate and monthly process audits, we guarantee consistency, speed, and reliability — project after project.

Over 40% of clients return with repeat orders for 5+ years, proving that our results speak louder than claims.

We deploy cutting-edge equipment to guarantee unmatched precision:

We have a professional team certified with ISO 9001:2015 and implement systematic testing at all stages of manufacturing:

With 20+ years of expertise, Samshion delivers:

Not only high demand automotive parts, but also aerospace turbine components with micrometer level tolerances to biocompatible prototypes for advanced medical devices, Samson transforms technical challenges into practical products – fast, accurate, and compliant.

Explore how our ISO certified manufacturing ecosystem helps global innovators deliver unparalleled quality from design to delivery.