What is 6061 Aluminum CNC Machining?

In the competitive landscape of modern manufacturing, 6061 aluminum has emerged as the premier choice for engineers and designers worldwide. Known for its exceptional versatility, it serves as the backbone of rapid prototyping and high-precision production. At Samshion Rapid, we leverage the unique properties of this alloy to deliver components that balance structural integrity with cost-effectiveness.

Overview of 6061 Aluminum as a Preferred Material

6061 aluminum is a precipitation-hardened alloy, containing magnesium and silicon as its major alloying elements. It is widely regarded as the most machinable aluminum grade, offering a perfect harmony of mechanical strength, weldability, and corrosion resistance. For CNC machining services, this material allows for high-speed material removal while maintaining the sharp edges and fine details required for complex designs.

Why 6061 Aluminum is the Industry Standard at Samshion Rapid

At Samshion Rapid, we recommend 6061 aluminum for CNC prototyping because it addresses the three most critical needs of our clients: Speed, Precision, and Stability.

High Machinability

It allows our CNC machines to run at optimal speeds, reducing lead times for urgent Rapid Prototyping projects.

Excellent Stability

Unlike softer alloys, 6061 holds its shape during and after machining. When we use 6061-T651 stress-relieved plates, we can guarantee minimal deformation, which is crucial for parts requiring a high degree of flatness.

Surface Versatility

It responds exceptionally well to post-processing treatments like anodizing, which is a core offering in our finishing department.

Typical Industries Utilizing Our 6061 CNC Prototypes

Our specialized 6061 aluminum CNC machining supports innovation across a wide array of high-tech sectors:

Aerospace and UAV Components

Lightweight structural brackets, sensor mounts, and engine housings where every gram counts.

Automotive Prototypes

Functional engine parts, custom suspension components, and dashboard frames for EV development.

Industrial Equipment and Fixtures

High-precision jigs, inspection tools, and robotic end-effectors that require durability and repeatable accuracy.

Consumer and Electronic Enclosures

Sleek, heat-dissipating casings for high-end electronics and communication devices.

Is 6061 Aluminum the Best Choice for Your CNC Prototype?

At Samshion Rapid, we believe that successful prototyping starts with the right material science. While many alloys are available, 6061 aluminum is our go-to recommendation for over 80% of CNC projects due to its predictable behavior during the machining process and its reliable performance in the field.

Machinability and Stability

The success of rapid CNC prototyping depends on how a material reacts under the cutting tool. 6061 aluminum is engineered for stability.

Excellent Machinability for High-Speed CNC Milling

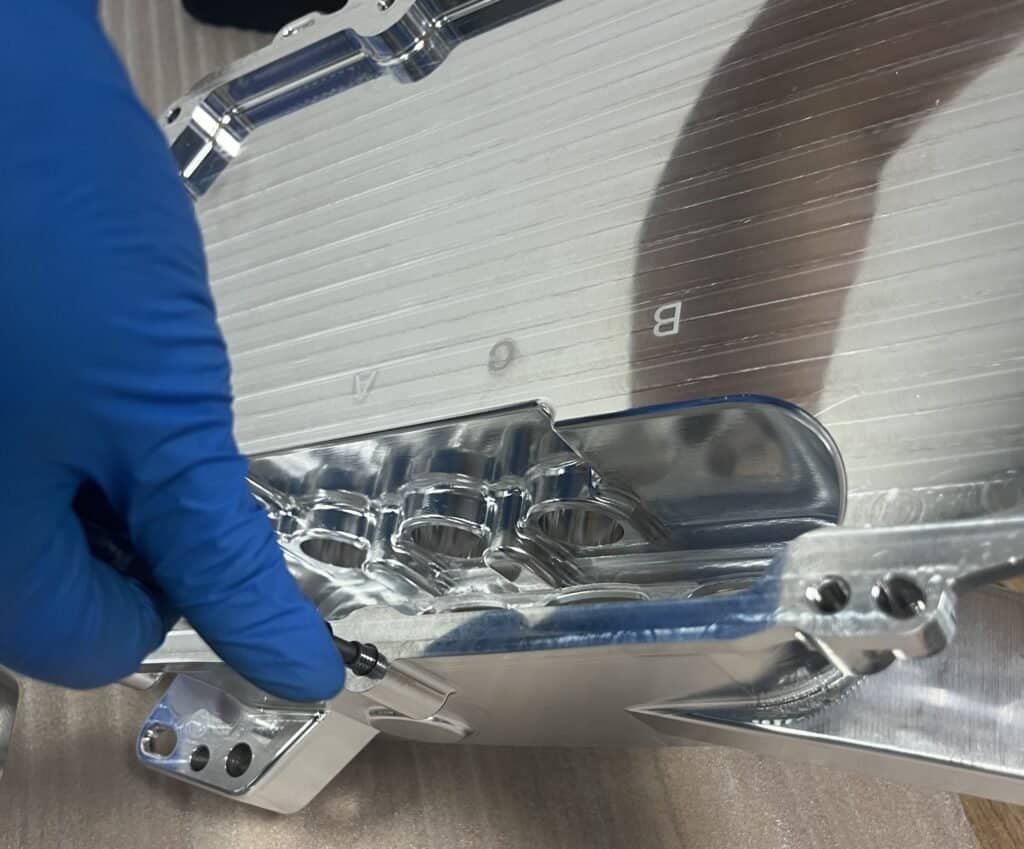

6061 is categorized as a free-machining alloy. At Samshion Rapid, this allows us to utilize high-speed spindles and aggressive feed rates, significantly reducing the lead time for your prototypes. It produces clean, manageable chips, which prevents tool clogging and ensures a superior as-machined surface finish.

Low Internal Stress for Tight-Tolerance Prototypes

One of the biggest challenges in CNC machining is part warping. To combat this, we prioritize the use of 6061-T651 tempered aluminum. The stretching process involved in T651 temper relieves the internal residual stress found in standard plates. This ensures that when we machine complex, thin-walled prototypes at Samshion Rapid, they remain flat and dimensionally stable within ± 0.01 mm.

Consistent Results for Design Validation

For engineers, consistency is key. 6061 provides a stable baseline for functional testing. Whether you order one prototype today or fifty next month, the material’s uniform grain structure ensures that your design validation results are repeatable and accurate.

Mechanical Performance for Functional Prototypes

A prototype from Samshion Rapid is not just a visual model; it is a functional component designed to endure real-world stress.

High Strength-to-Weight Ratio

6061 offers a yield strength comparable to some mild steels but at only one-third of the weight. This makes it ideal for functional aluminum prototypes in the robotics, UAV, and automotive sectors where reducing mass is critical to performance.

Good Corrosion Resistance Without Coating

While we offer a full range of finishes, 6061 naturally forms a protective oxide layer. This allows for immediate functional testing in various environments such as humid or outdoor conditions without the immediate need for expensive coatings.

Suitable for Load-Bearing Prototype Parts

Unlike softer series such as 5xxx or 1xxx, 6061-T6 possesses the hardness required for load-bearing applications. It holds threads well and can withstand mechanical fastening, making it perfect for structural assemblies and industrial fixtures.

What CNC Equipment is Used for Machining 6061 Aluminum?

To unlock the full potential of 6061 aluminum, a manufacturer must possess a diverse range of equipment. At Samshion Rapid, we operate a state-of-the-art machine shop equipped with varied CNC platforms, ensuring that every 6061 aluminum CNC machining project is executed on the most efficient machine for its specific geometry.

CNC Milling Machines

Milling is the primary method for creating prismatic aluminum parts. Our facility utilizes a tiered milling approach:

3-Axis CNC Milling

The workhorse for simple prototype geometries. It is the most cost-effective solution for brackets, plates, and parts with features on a single plane.

4-Axis CNC Machining

By adding a rotary axis, we can machine indexed features around a cylinder or on multiple sides of a part without manual repositioning. This reduces human error and improves the alignment of complex features.

5-Axis CNC Machining for Complex Prototypes

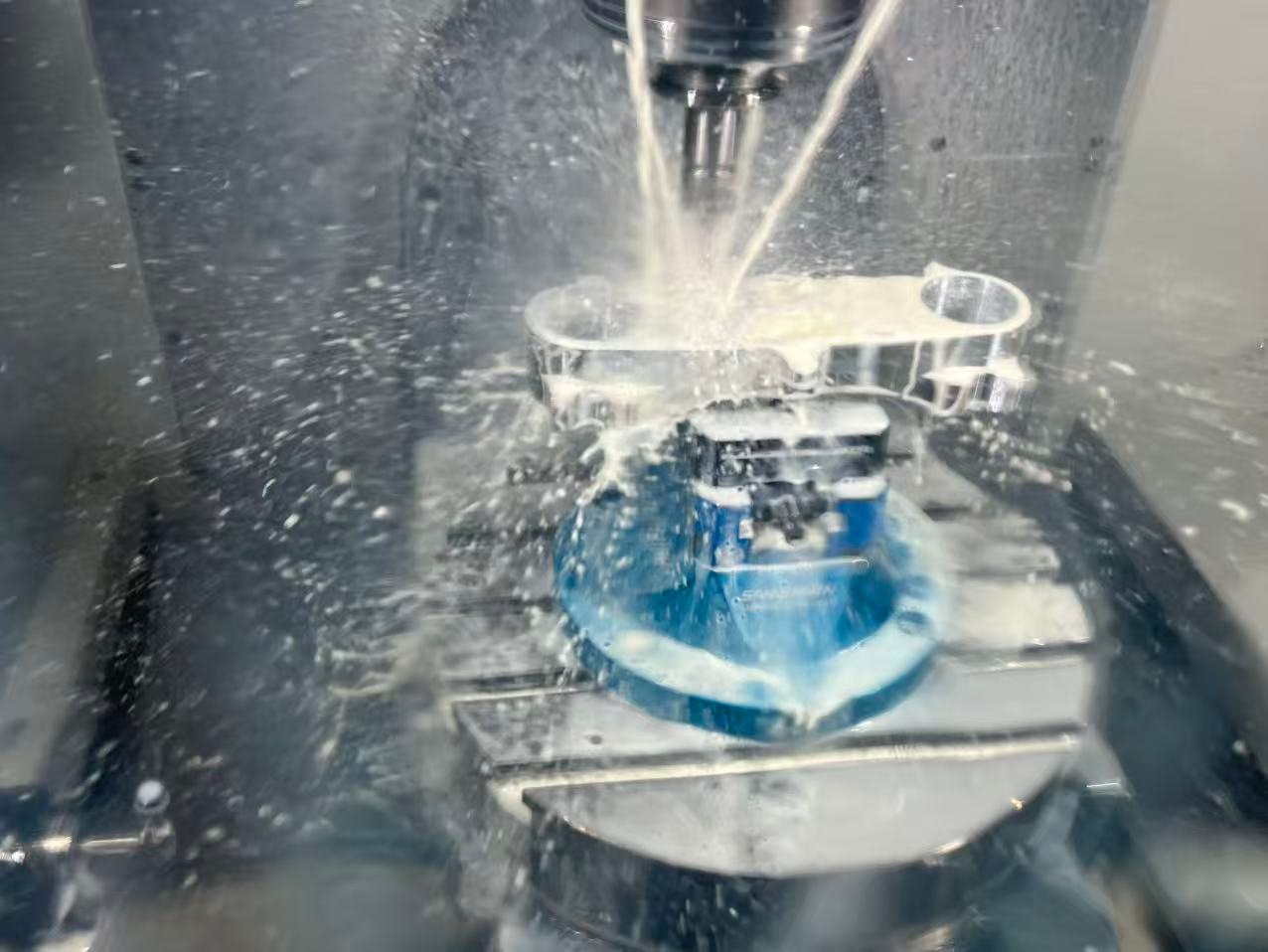

For aerospace housings or organic medical designs, our 5-axis CNC prototyping capability is essential. It allows the cutting tool to approach the 6061 block from any angle, enabling complex undercuts and deep cavities that are impossible with 3-axis machines.High-Speed Spindle Advantages

6061 aluminum thrives at high speeds. Our machines feature high-RPM spindles that allow for high Surface Feet per Minute (SFM). This not only speeds up production but also generates a superior, mirror-like surface finish by minimizing tool pressure and heat buildup.

CNC Turning (Lathe Machining)

Not all prototypes are blocky. For cylindrical components, CNC turning is the most precise method.

Precision Turning

Ideal for round or symmetrical prototype parts like shafts, bushings, and pulleys. We maintain strict concentricity to ensure these parts perform perfectly in rotating assemblies.

Turn-Mill Centers

For multi-feature aluminum components such as a shaft with milled flats or cross-holes, our turn-mill centers handle everything in a single setup. This Done-in-One philosophy at Samshion Rapid eliminates the accuracy loss that occurs when moving parts between different machines.

CNC Drill-Tap Centers for Rapid Prototypes

When a design features hundreds of tapped holes, common in heat sinks and electronic mounting plates, standard milling machines can be slow.

Fast Cycle Times

Our dedicated drill-tap centers are optimized for rapid tool changes and high-speed hole making.

Small-Batch Efficiency

These machines are ideal for small-batch aluminum prototype production (10–100 pieces). They allow us to deliver Rapid results without compromising the thread quality or positional accuracy of the holes.

How Does Samshion Rapid Optimize the Machining Process?

Precision in 6061 aluminum prototyping is the result of controlled processes. Samshion Rapid team do not just cut to print; we optimize the tool path and machining strategy to manage heat and material stress, ensuring your prototype is as accurate as the digital model.

Milling, Drilling, and Tapping

The way a tool interacts with 6061 aluminum determines the final quality. We focus on three critical areas:

High-Speed Milling Strategies

We utilize trochoidal milling and high-speed surfacing paths. By maintaining a constant tool load, we reduce the vibration that often causes surface chatter, resulting in a cleaner finish and more accurate dimensions.

Efficient Chip Evacuation

6061 can become gummy if heat builds up. Our CNC setups use high-pressure localized coolant or air blasts to ensure chips are cleared instantly. This prevents re-cutting of chips, which is a common cause of poor surface quality in aluminum parts.

Thread Machining vs. Tapping

In the prototype stage, we often prefer thread milling over traditional tapping. Thread milling allows us to control thread fit precisely and eliminates the risk of a tap breaking inside a nearly finished, expensive prototype.

Tolerance Capabilities

Achieving tight tolerances in aluminum requires a deep understanding of the material’s thermal expansion.

Typical CNC Tolerances

For standard 6061 aluminum CNC machining, we easily maintain ± 0.005 mm. However, for high-precision aerospace or medical components, We regularly achieves ± 0.005 mm through careful tool calibration and climate-controlled machining environments.

Cost vs. Precision

We always provide transparent feedback. When a design calls for ultra-tight tolerances below ± 0.005 mm, it requires specialized inspection and slower machining cycles, which increases the prototype cost. We work with you to ensure tolerances are as tight as necessary, but as cost-effective as possible.

Prototype-to-Production Consistency

One of the greatest advantages of choosing us is the seamless transition to scale.

Identical Processes

We use the same industrial-grade CNC centers for a single prototype as we do for a batch of 1,000. This ensures that the mechanical properties and surface integrity of your prototype will perfectly match the final mass-produced parts.

Reducing Design Risk

By validating your design with a CNC-machined 6061 prototype, you eliminate the risks associated with other methods such as 3D printing. Fitment, thread strength, and structural rigidity are verified before you commit to expensive hard tooling or large-scale production runs.

Which Surface Finishes are Best for 6061 Aluminum Prototypes?

A prototype is often the first time a stakeholder sees or handles a new design. Therefore, the look and feel are just as important as the dimensions. 6061 aluminum is an ideal substrate for a wide variety of finishes. Samshion offer integrated surface treatment services to ensure your CNC prototype surface finish meets both aesthetic and functional requirements.

As-Machined Finish for Early-Stage Prototypes

For internal components or early-stage fit-check models, an as-machined finish is the most cost-effective choice.

Quality Assurance

Even without post-processing, our high-speed spindles and sharp diamond-tipped tools produce a clean surface with visible but smooth tool marks (typically Ra 1.6–3.2 μm).

Precision

This finish is ideal when you need to verify the exact tight tolerance aluminum machining results without any additional coating thickness affecting the dimensions.

Bead Blasting for Cosmetic Appearance

To achieve a premium, non-reflective matte look, we utilize bead blasting.

Texture

By blasting the 6061 surface with fine glass beads, we remove directional tool marks and create a uniform satin texture.

Application

This is a favorite for electronic enclosures and handheld devices, as it resists fingerprints and provides a professional, high-end aesthetic.

Anodizing (Clear, Black, Hard Anodize) for Functional Testing

Anodizing is the most popular treatment for 6061 aluminum prototyping because it creates a hard, non-conductive protective layer.

Type II (Decorative)

Available in clear, black, or custom colors. It provides excellent corrosion resistance and a vibrant look.

Type III (Hard Anodize)

For prototypes used in high-wear or abrasive environments. Hard anodizing significantly increases the surface hardness of 6061, making it suitable for load-bearing and sliding components.

Functional Testing

Anodizing is essential for verifying how a part will behave in its final production environment, especially concerning electrical insulation and chemical resistance.

Powder Coating for Aesthetic Prototype Evaluation

When your prototype needs to match a specific brand color or require a thick, durable protective shell, powder coating is the solution.

Durability

It offers a much thicker coating than anodizing, capable of withstanding heavy impact and harsh outdoor conditions.

Aesthetics

With a vast range of RAL colors and textures (glossy, matte, or sand-texture), we use powder coating to help you perform accurate aesthetic evaluations before mass production.

What Design Considerations Should You Follow for 6061 Machining?

When designing CNC prototypes in 6061 aluminum, careful planning ensures both manufacturability and functional performance. At Samshion Rapid, we provide design guidance to optimize prototypes for machining efficiency, cost, and reliability.

Minimum Wall Thickness Recommendations

Maintaining adequate wall thickness is crucial to prevent deformation during machining and ensure structural integrity. Our engineers advise the minimum thickness based on the part geometry and machining method.

Fillets and Internal Corner Radii for Tool Access

Sharp internal corners are difficult to machine and increase stress concentrations. Adding fillets and proper corner radii allows tools to access internal features easily and improves the durability of the part.

Hole Depth and Thread Design for CNC Machining

Hole depth, diameter, and threading need to follow best practices to prevent tool breakage, maintain tolerance, and ensure proper fit for assembly. Samshion Rapid provides recommendations for optimal hole placement and thread engagement.

Design for Manufacturability (DFM) Feedback in Prototype Phase

Before finalizing the prototype, we review the design for manufacturability. This process helps identify potential challenges, reduce iteration cycles, and ensures the part can transition smoothly to small-batch or mass production.

How Does 6061 Aluminum CNC Machining Cost?

Material Cost vs. Machining Time

While 6061 aluminum is a relatively affordable raw material, the bulk of your invoice is usually determined by spindle time.

Material Efficiency

6061 is chosen for rapid CNC prototyping specifically because it can be cut at very high speeds (High MRR – Material Removal Rate).

The Trade-off

A design that requires removing 90% of a large aluminum block to create a thin-walled part will cost more in machining time and waste than a design that utilizes standard stock sizes efficiently.

Complexity and Number of Setups

The most significant “hidden” cost in CNC machining is the labor involved in setups and fixturing.

Setup Time

Every time a technician has to stop the machine, rotate your part, and re-calibrate the coordinates, the cost increases.

5-Axis Advantage

At Samshion Rapid, we often use 5-axis CNC machining to handle complex geometries in a single setup. While the hourly rate for a 5-axis machine is higher, it often reduces the total CNC prototype cost by eliminating multiple manual setups and custom jigs.

Tolerance and Surface Finish Impact

Not every feature on a prototype needs to be perfect.

Precision Costs

Achieving a ± 0.005 mm tolerance requires slower cutting passes, specialized measuring tools, and sometimes climate-controlled environments. If a feature only requires ± 0.005 mm, designing it as such will significantly lower the price.

Finishing Labor

An as-machined finish is the baseline. Adding processes like bead blasting or hard anodizing adds labor and external processing time. We recommend prioritizing high-end finishes only for the final validation prototypes or “show” models.

Batch Size: One-off Prototype vs. Small-Volume Production

The Price Per Part drops dramatically as you move from a single unit to a small batch.

The One-off Challenge

For a single prototype, the cost includes all the programming (CAM), tool selection, and machine setup.

Economies of Scale

Once the program is optimized and the tools are loaded, producing 10 to 50 pieces is much more efficient. Samshion Rapid specializes in bridging this gap, offering competitive pricing for small-volume production so you can move from a single test unit to a pilot run without a massive jump in budget.

6061 vs. Other Alloys: Which One Should You Choose?

While 6061 is the all-rounder of the industry, certain applications require specific properties. At Samshion Rapid, we help you navigate the selection process to ensure your aluminum alloy prototyping choice matches your part’s end-use.

6061 vs. 5052 for CNC Prototyping

Machinability

5052 is a softer alloy, often used for sheet metal. When it comes to 6061 vs 5052 machining, 6061 is far superior for CNC milling. 5052 tends to be gummy, sticking to the cutting tool and making it difficult to achieve a high-quality surface finish or tight tolerances.

Application

If your prototype requires complex CNC-milled features, Samshion Rapid always recommends 6061. We reserve 5052 primarily for parts that require significant bending or sheet metal work alongside basic machining.

6061 vs. 7075 for Strength-Critical Prototypes

The Power of 7075

Known as Aerospace Grade, 7075 aluminum offers significantly higher strength—comparable to many steel alloys. However, it is more expensive and harder to machine.

The Choice

In 6061 vs 7075 machining, we recommend 7075 for functional prototypes that will undergo extreme mechanical stress, such as high-load aerospace brackets or racing components.

Stability

7075 is highly stable but more prone to corrosion than 6061. If your prototype is for environmental testing without anodizing, 6061 is often the safer, more cost-effective choice.

Selecting the Right Aluminum Alloy at the Prototype Stage

Choosing the right material at the start of your rapid CNC machining project prevents costly redesigns later. Our engineering team evaluates your project based on:

Mechanical Load: Does it need the extreme strength of 7075?

Environmental Exposure: Does it need the corrosion resistance of 6061?

Post-Processing: Are you planning for decorative anodizing (6061 is best) or hard-coat anodizing?

Why Choose CNC Machining for 6061 Aluminum Prototypes

In an era of 3D printing, 6061 aluminum CNC machining remains the dominant force for professional-grade prototypes for several reasons:

Faster Lead Times

For simple to moderately complex parts, Samshion Rapid can deliver CNC prototypes in as little as 3–5 days, rivaling the speed of additive manufacturing.

High Dimensional Accuracy

CNC machining provides repeatability that 3D printing cannot match, maintaining ± 0.005 mm across a batch.

Material Integrity

Unlike printed parts, CNC-milled 6061 prototypes are made from a solid, forged block of metal, meaning they possess the exact mechanical properties of the final production part.

Conclusion: How to Start Your 6061 Prototyping Project?

6061 aluminum is more than just a material; it is a versatile solution for bringing complex designs to life. However, the quality of your prototype is only as good as the partner you choose to machine it.

Samshion Rapid has combined advanced 5-axis CNC prototyping technology with deep expertise in managing residual stress and material stability. Whether you need a one-off functional model or a small-volume production run, our goal is to reduce your design risk and accelerate your path to market.

Ready to start your next 6061 aluminum project? [Contact Samshion Rapid today for a free DFM report and a competitive quote.]