In this post, we’ll break down the costs, benefits, and potential of laser engravers, and how to use lasers to create personalized engravings for custom business.

At Samshion, our team has extensive experience in rapid prototyping and precision machining. We provide professional manufacturing services to meet the products requirement of hobbyists and businesses.

If you’ve ever wondered what the potential of laser engraving could be, you’re not alone in today’s world of customization. Many business people and creative people ask, is it worth buying a laser engraving machine? Laser engravers are becoming powerful tools for any kind of customization, branding, and even industrial purposes due to the increasing demand for personalized engravings. Does the investment yield a dividend worth it?

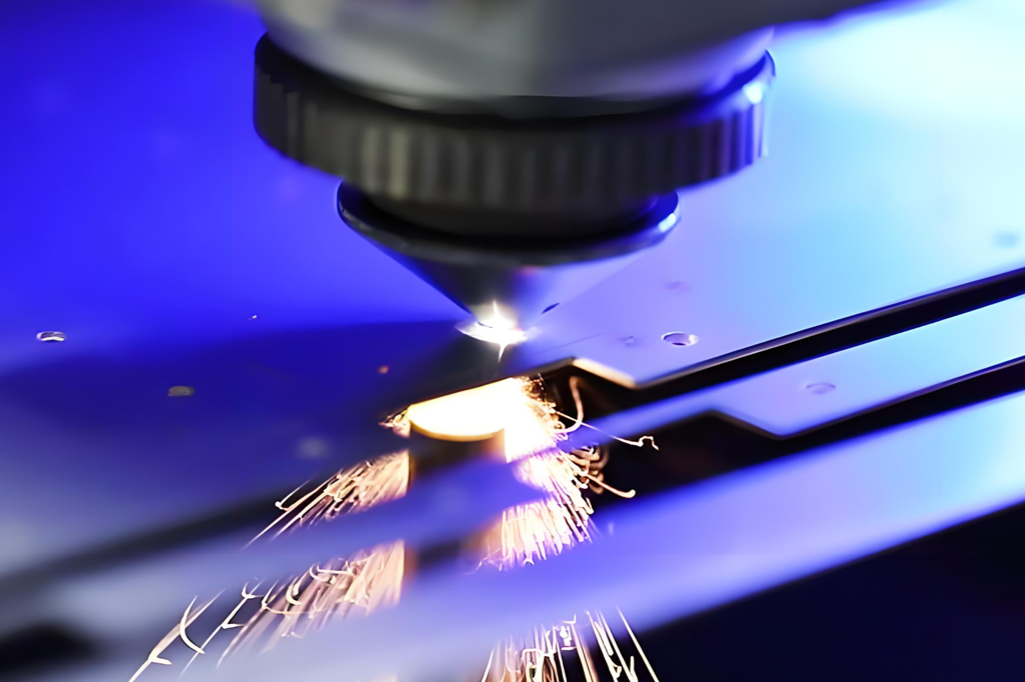

If you want to begin a profitable business or if you want to just express your creative side, then you are at the right place with a laser engraving machine. The technology that provides precision and efficiency for crafting custom gifts as well as engraving fine details on wood, metal, and acrylic simply cannot be either achieved with efficiency or the art that is provided with traditional methods.

The Samshion team often advises clients on material selection, process parameters, and design considerations to ensure maximum precision and efficiency for each project. Here are some of our analyses and thoughts.

What Are Personalized Laser Engravings and Why Do They Matter?

So in this guide, Samshion go over all that you would want to know and help you decide once you run through everything to determine whether a laser engraver is the right tool for you. In this post, let’s see whether owning one is advantageous for you, how challenging it could be, and whether it’s profitable or not in real life.

Laser engraving allows precise, detailed designs to be applied on a variety of materials. This technology supports creativity while maintaining repeatability and quality that manual methods cannot match. frequently demonstrates to clients how laser engraving can reduce errors and improve design consistency across multiple prototypes or production batches.

Where Can This Type of Machine Be Applied in Our Projects?

At Samshion, our experts help evaluate how engraving technology can integrate into existing workflows, considering both business scale and production requirements.

We often use this machine in manufacturing aerospace or craft parts, carving symbols according to customer needs. Even all of our fixtures, tooling, and inspection tools use this type of machine to engrave the Samshion logo. Today, laser engraving is used in a wide range of industries — from jewelry and signage to industrial labeling and product branding. The trend of personalization has grown rapidly over the past five years, and in 2025 the global laser engraving market continues to expand at a steady rate. This makes the investment not just practical but strategic for businesses looking to stand out.

How Do Costs Compare to Value in Laser Engraving?

The price range for laser engraving units starts at several hundred dollars and extends to several thousand dollars for diverse models and power levels. A high initial investment into laser engraving machines becomes worthwhile since their ability to deliver exact results along with increased operational efficiency and adaptable capabilities surpasses the initial funding cost. Regular engraving project work leads to sufficient savings through outsourcing that should compensate for your purchase.

For example, a small 40W CO₂ laser machine may cost around $500–$1,000, while a mid-range fiber laser suitable for metal engraving can reach $5,000–$10,000. Yet, many small workshops report recovering this cost in under a year by taking custom orders for corporate gifts, awards, and branding plates.

Samshion provides guidance on cost-benefit evaluation, helping clients determine the right machine type to match their workload and material requirements.

How Can a Laser Engraver Increase Profit for Business Owners?

As far as we know, there are many companies around us that provide laser engraving services, mainly providing outsourced parts engraving services.

Getting started with business operations or growing your business involves using a laser engraver that serves as a profitable business instrument. The steady profit flow for entrepreneurs comes from creating customized items that include wooden signs together with tumblers and jewelry pieces as well as leather-based goods. Small laser engraving companies can now access global customers through e-commerce gates including Etsy and Amazon.

Laser engraving opens the door to countless niches: wedding décor, promotional giveaways, personalized electronics, and luxury packaging. These high-margin products can boost a small company’s visibility and profitability while maintaining a manageable level of production cost.

Is a Laser Engraver Only for Hobbyists or Can It Be a Serious Tool?

At Samshion, we typically use carving machines for complex or high-precision services, but we do not consider it a serious tool. We would recommend amateur enthusiasts to start with low-power models to gain experience and reduce the risk of material waste while learning carving techniques.

We think that laser engravers create unlimited opportunities for self-entrepreneurs to explore their creative projects. A laser machine provides excellent value for workshops by enabling intricate glass designs and it becomes a useful tool for making personalized items. The benefits from having this equipment yourself will only provide value when you use it regularly; otherwise, outsourcing would be the more cost-effective solution.

For many DIY creators, owning a compact desktop engraver is like having a personal art studio at home. They can design wood ornaments, metal nameplates, or acrylic displays. Individual artists can unleash their artistic talents and abilities infinitely, and a reasonably priced carving machine would be a very interesting tool. However, if your creative needs are limited, occasional outsourcing to a local maker space might still make more financial sense.

How Easy Is It to Learn Laser Engraving?

High precision engraving machines require operators like Samshion to have experience operating five axis or three-axis machines and fully understand the essentials of milling.

But reasonable cost carving machines on the ordinary market are actually easier to learn. An ambitious users can easily learn laser engraving operations since modern machines include user-friendly programs with easy-to-understand interfaces. The learning process of engraving techniques together with material compatibility knowledge requires consistent practice. Your engraving outcomes will improve through the combination of learning online tutorials, testing various settings, and dedicating your time to skill development. New users can rely on free design software such as LightBurn or EZCAD, plus video tutorials across YouTube and manufacturer training materials, to become proficient within weeks. With patience, anyone can master the basics and start producing professional-quality engravings.

How Important Is Maintenance and Longevity for a Laser Engraver?

A good laser engraver will last for years but schedules need to be kept, which can take up much of the time. To maintain optimal performance, the lenses need to be cleaned, alignment checked, and worn-out parts replaced. Getting a dependable brand machine will save you in the long run by way of low maintenance and increased durability.

Leading brands such as Epilog, OMTech, and Glowforge offer models that can last 5–10 years with minimal upkeep, provided the operator performs simple maintenance like cleaning mirrors and checking belts. This longevity helps justify the initial purchase price over time.

Who Should Consider Buying a Laser Engraving Machine: Hobbyists or Professionals?

A laser engraving machine is a very powerful tool, but is it the right investment for you? For professional prototype manufacturers like Samshion, this machine is undoubtedly very important. Whether you are a hobbyist who has an appetite for exploring creative projects or have a business in mind, you will decide whether purchasing one will benefit you or not.

Hobbyists: Ideal for DIY enthusiasts to customize gifts, home décor, or experiment with materials. Laser engravers provide precision and detail that traditional methods cannot achieve.

Professionals: A revenue-generating asset for businesses. Reduces outsourcing, speeds production, and allows expansion into multiple product lines, including metals, glass, plastics, and fabric.

Samshion can advise both groups on machine selection, material compatibility, and workflow integration to ensure the investment is optimized.

So what is the actual return on investment in laser engraving for a small business?

Based on the total price mentioned earlier, we believe that you need to identify your business positioning, whether you are a CNC or rapid prototyping company like Samshion, a small craft manufacturing company, or an individual enthusiast.

If you are considering adding laser engraving services, Samshion’s guide breaks down the factors such as cost, profit potential, and market demand that will make you think about whether a laser engraving machine is financially worth it or not.

Laser engraver cost varies dramatically: from $600 for entry-level environments to $50,000 or more for industrial-level machines. Even with a slightly large outlay, if your laser engraver is used well and there are constant jobs and/or custom product sales, the laser engraver will quickly pay for itself. The business can see a turnaround of positive returns within months by reducing outsourcing costs and enhancing production efficiency.

Items are sold at a premium price due to them being custom and personally engraved. Products like engraved wooden gifts, metal plaques, leather wallets, and acrylic signage will have a big markup. You can spend a few cents on the material cost of a small engraved keychain but they can sell for $10 or more. Therefore, the very high profit-to-cost ratio enhances overall revenue.

An advantage of a laser engraver is that it enables small businesses to add new product lines. This will allow you to cater to different markets such as wedding gifts, corporate branding, personalized home décor, and industrial engraving. If in multiple niches, a business guarantees a steady stream of the orders, which in turn reduces the risks associated with seasonal trends or market fluctuations.

Laser engravers make production so much faster than manual methods that it’s unprofitable to try and use massive amounts of people for manual work. This enables businesses to complete more orders in less time using a machine that can do intricate designs in minutes. This all means higher efficiency results in higher sales potential and a quicker break-even point.

Laser engraving machines also have lower operating costs as compared to many industrial machines. They use very little electricity, and except for their lenses and tubes, ones need to be changed only occasionally. Longevity and long-term expense savings are all reduced long-term profits.

Should You Choose a Portable or Industrial Laser Engraver?

Portable machines: Compact, lightweight, cost-effective for small projects. Best for soft materials like wood, acrylic, and leather.

Industrial machines: Higher power, faster production, and compatibility with metals, glass, and stone. Suitable for large-volume operations.

Samshion advises businesses to match machine choice to material types, production speed requirements, and workspace constraints to maximize long-term value.

How Can a Laser Engraving Machine Be Used Creatively for Business?

Laser engraving has versatile applications:

Identification of high-precision parts: Aviation, automotive and other parts will be engraved with the company’s logo

Custom Gifts: Wood, leather, acrylic, and metal items engraved with names, quotes, or images

Corporate Branding: Logo engraving on pens, USB drives, business cards, and plaques

Home Décor: Wall art, coasters, mirrors, and decorative panels

Industrial Applications: Serial numbers, QR codes, machine parts, and labels

Jewelry & Accessories: Pendants, bracelets, rings, belts, and wallets

DIY Craft Business: Selling custom engraved items or providing templates for other creators

Final Thought: Is a Laser Engraver the Right Choice for You?

The decision to invest in a laser engraver depends on your intended usage:

Regulr use: Justifies the investment through efficiency, quality, and new revenue streams

Occasional projects: Outsourcing may remain more practical Under the analysis of the Samshion team, we hope that you can choose the appropriate machine. We use this technology to meet our customers’ prototype and part requirements, optimize workflows, and maximize the advantages of laser engraving – whether it is shaping the brand or business growth.