CNC machining is a versatile manufacturing process employed to create high-precision components across industries. Businesses opt for CNC production machining based on critical factors like cost efficiency, material compatibility, and scalability, with distinct advantages for varying production volumes—from prototypes to mass batches.

This article demystifies CNC production machining, breaking down its complexities into actionable insights. We explore key terminology, operational workflows, and essential considerations for outsourcing, equipping you with the knowledge to optimize your manufacturing strategy.

Why Choose CNC Production Machining?

While CNC machining is a well-understood process, mastering CNC production machining requires deeper insight into its operational workflows—whether you operate in-house machines or outsource production. Staying competitive demands familiarity with the nuances of scaling from prototypes to mass batches.

CNC production machining is broadly categorized into two approaches: low-volume CNC machining and high-volume CNC production machining. Though their names hint at their purposes, their strategic benefits and applications extend far beyond mere quantity. Below, we dissect both methods to help you optimize your manufacturing strategy.

Low-Volume CNC Machining

Low-volume CNC machining focuses on producing 10–1,000 units, ideal for prototypes, bridge production, or niche-market products. It prioritizes flexibility and cost efficiency, enabling rapid design iterations without hefty tooling investments. Key advantages include:

Reduced Lead Times: Deliver functional parts in 1–3 weeks.

Material Versatility: Machine metals (aluminum, stainless steel) and plastics (POM, ABS) with equal precision.

Scalability: Transition seamlessly to high-volume runs once designs are validated.

Industries like aerospace, medical devices, and automotive leverage low-volume CNC for testing components under real-world conditions.

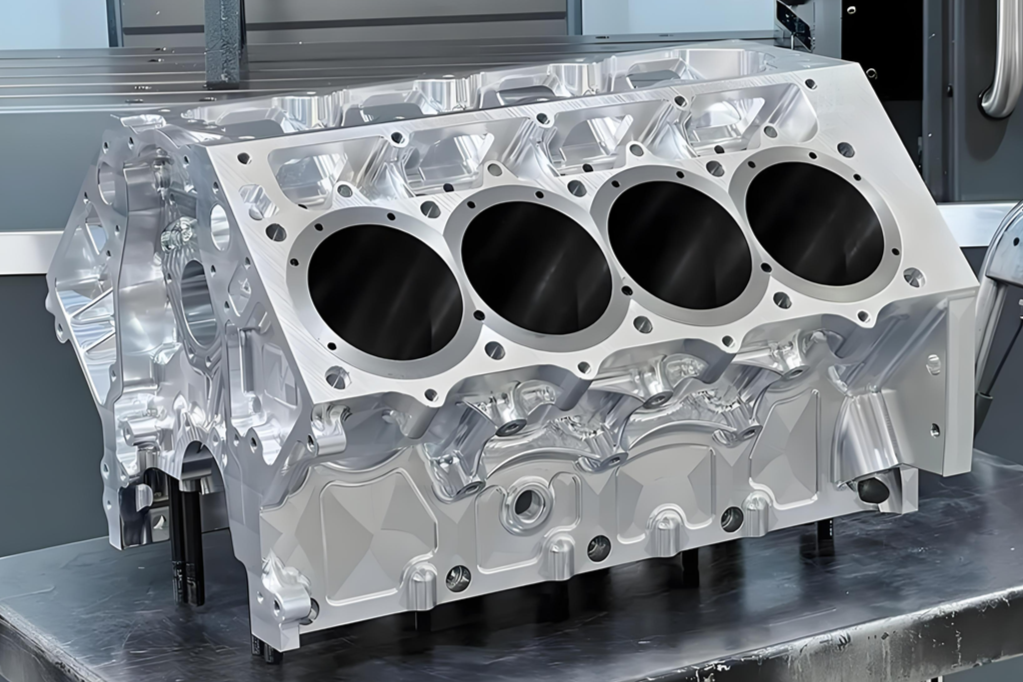

High-Volume CNC Production Machining

High-volume CNC manufacturing caters to 1,000+ units, optimizing economies of scale for mass production. This method emphasizes consistency, repeatability, and per-unit cost reduction. Benefits include:

Cost Efficiency: Lower per-part costs through automated workflows and bulk material purchasing.

Precision at Scale: Maintain tolerances as tight as ±0.025 mm across thousands of units.

Streamlined Supply Chains: Integrate with just-in-time (JIT) manufacturing to minimize inventory costs.

High-volume CNC is pivotal for consumer electronics, industrial machinery, and automotive sectors requiring large quantities of identical parts.

Benefits of CNC Production Machining

CNC production machining delivers unmatched efficiency and cost-effectiveness for both low- and high-volume manufacturing. By prioritizing automation and precision, it minimizes waste, reduces labor dependency, and maximizes profitability—key advantages for industries seeking scalable, competitive solutions.

Enhanced Efficiency & Minimal Waste

CNC production machining relies on advanced software and automated workflows to optimize material usage and reduce scrap. Precision toolpaths and multi-axis capabilities ensure consistent output, while real-time monitoring minimizes errors. For example, nesting algorithms maximize raw material utilization, cutting waste by up to 20% compared to manual methods.

Reduced Labor Dependency

While skilled technicians oversee operations, CNC machining significantly reduces manual intervention. Automated tool changes, continuous operation, and pre-programmed workflows lower labor costs by 30–50%, freeing teams to focus on quality control and process optimization.

Higher Profitability

CNC’s scalability directly boosts profitability. Low-volume runs benefit from competitive per-unit pricing, while high-volume production leverages economies of scale. Reduced labor, material waste, and rework costs increase margins by 15–25%, making CNC ideal for price-sensitive markets.

Must-Know Tips for Outsourcing Production CNC Machining

Before outsourcing your CNC machining project, understanding key processes and requirements ensures a seamless collaboration. Below, we outline three critical considerations to optimize your workflow and outcomes.

1. Standard Production Process

CNC production machining follows a streamlined workflow divided into four core stages:

Design a CAD Model

The first step involves creating a CAD (Computer-Aided Design) file in 2D or 3D format using software like SolidWorks or AutoCAD. This digital blueprint defines your part’s geometry, dimensions, and technical specifications. Ensure your design aligns with material constraints (e.g., machinability, thermal properties) and CNC capabilities (e.g., tool access, undercuts).

Convert the CAD File to a CNC Program

After finalizing the CAD design, the next critical step is translating it into machine-readable instructions using CAM (Computer-Aided Manufacturing) software. This software analyzes the CAD file’s geometry and generates the programming codes required to execute CNC operations.

In CNC machining, two primary code types drive the process:

G-code (Geometric Code): Controls the machine’s movements, including toolpaths, feed rates, and spindle speeds. It dictates how and where the tool moves to shape the workpiece.

M-code (Miscellaneous Code): Manages auxiliary functions like tool changes, coolant activation, or program stops. It governs when and what non-cutting actions occur during machining.

CAM software automates G/M-code generation, ensuring precision and minimizing manual programming errors. Advanced systems also simulate toolpaths to detect collisions or inefficiencies before machining begins.

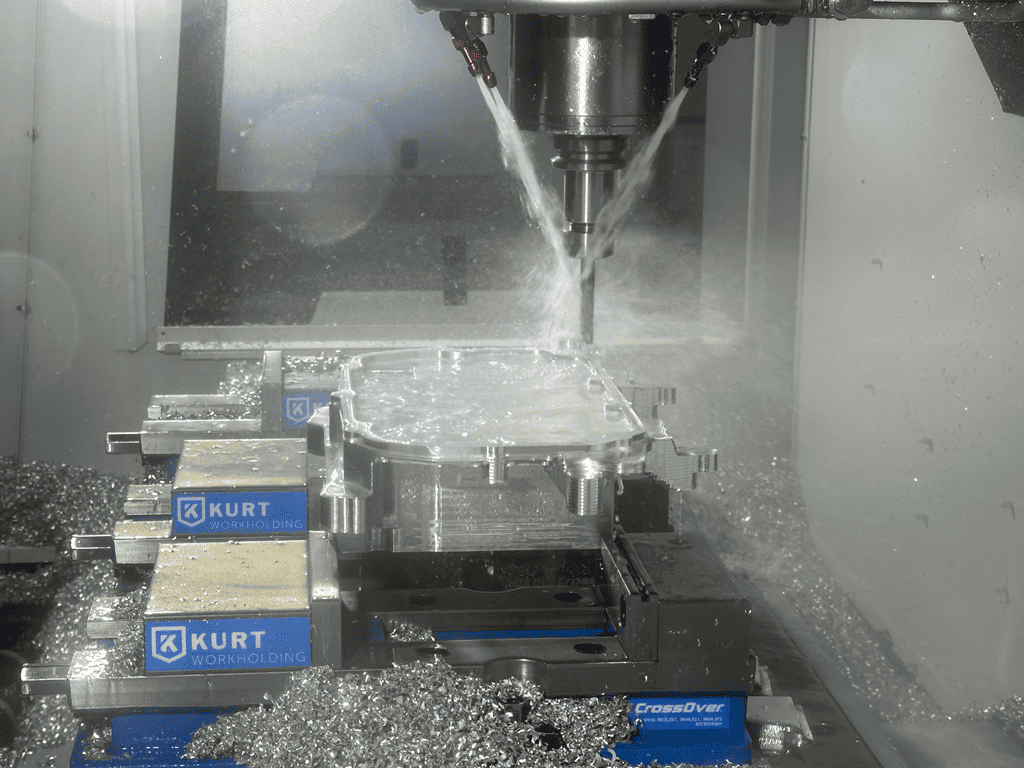

Setting Up the CNC Machine

Setting up the CNC machine involves configuring equipment and workflows tailored to your production volume—whether high-volume mass production or low-volume prototyping. This process varies based on machinery type (e.g., turning centers, milling machines, grinding systems) and requires meticulous preparation to ensure precision, safety, and efficiency.

Key steps include calibrating tooling, securing workpieces, and inputting optimized G-code programs. For high-volume runs, engineers prioritize automated tool changers and multi-axis synchronization, while low-volume setups focus on rapid toolpath adjustments and material versatility. Regardless of scale, a skilled CNC engineer is essential to oversee machine calibration, troubleshoot errors, and maintain quality standards throughout the production cycle.

Execute the Operation

Once the CNC machine is calibrated and all parameters verified, initiate the machining process. The pre-programmed G-code controls the machine’s movements, toolpaths, and auxiliary functions (e.g., coolant flow, spindle speed), ensuring precise material removal and adherence to design specifications. Real-time monitoring systems track progress, while skilled operators intervene only for quality checks or unexpected deviations.

2. Design & Material Optimization

Achieving optimal part design requires aligning CAD models with material capabilities and CNC machining constraints. Below are key strategies to enhance manufacturability, reduce costs, and ensure precision.

Simplify the Design

Streamline your CAD model by eliminating unnecessary geometries that demand extra machining steps. Simplified designs minimize cycle times, reduce tool wear, and lower production costs. For example, consolidating multiple features into a single operation can cut machining time by 15–20%.

Optimize Wall Thickness

Balance structural integrity and machinability by selecting appropriate wall thickness. Excessively thin walls risk breakage during machining, while overly thick walls cause tool deflection or fracture. Ideal thickness ranges:

Metals: 0.8–5.0 mm

Plastics: 1.5–6.0 mm

Avoid Micro-Text & Complex Features

Small text, intricate engravings, or fine details increase machining complexity and costs. Opt for larger markings (≥3 mm font size) or post-process methods like laser etching for clarity and cost efficiency.

Use Standard Hole Sizes

Design holes to match standard drill bit sizes (e.g., 3 mm, 6 mm, 12 mm) to avoid custom tooling. This ensures faster setups, tighter tolerances (±0.05 mm), and reduced rework.

3. Quantity and Lead Time in CNC Manufacturing

In CNC manufacturing, balancing production quantity and lead time is critical to meeting project goals. While modern CNC providers accommodate both low- and high-volume orders, lead times vary based on software sophistication, machine capabilities, and operational efficiency. Understanding these dynamics ensures optimal quality, cost, and delivery speed.

For low-volume runs (10–1,000 units), lead times typically range from 1–3 weeks, leveraging rapid setups and minimal tooling. High-volume production (1,000+ units) extends lead times to 4–12 weeks, prioritizing economies of scale and automated workflows. Advanced providers optimize both scenarios through:

Real-Time Scheduling: AI-driven systems minimize bottlenecks.

Multi-Axis Machining: Parallel operations reduce cycle times.

Supplier Partnerships: Streamlined material sourcing cuts delays.

Choosing the right CNC partner hinges on their ability to align your volume needs with transparent timelines—ensuring prototypes or mass batches meet deadlines without compromising precision.

Rapid Precision CNC Machining Services

Tired of endless delays in design validation or sluggish production timelines? At Samshion, we redefine speed and quality in CNC machining. Whether you need low-volume prototypes or high-volume production runs, our advanced capabilities deliver 100+ precision parts in just 10 days—paired with instant quotes and expert DFM analysis. Simply upload your CAD files, and let our technology bridge the gap between concept and reality.