Choosing the right method for metal prototyping—CNC machining or additive manufacturing (AM)—requires balancing precision, cost, and scalability. While CNC delivers industrial-grade accuracy, AM offers unmatched design flexibility. This article breaks down the strengths of both technologies to help you decide which aligns best with your project goals.

Many assume CNC machining is reserved for mass production and AM for rapid prototyping. CNC excels in crafting high-tolerance parts from durable metals like aluminum and titanium, while AM minimizes upfront costs and accelerates iterative designs. Yet, the decision isn’t black-and-white. Both methods have unique roles in prototyping, influenced by factors like material compatibility, lead times, and post-processing requirements.

This guide explores the technical and economic trade-offs between CNC and AM, providing actionable insights for engineers and product developers.

CNC vs AM: Premium vs Economy?

At first glance, CNC machining appears costlier than 3D printing. Consumer-grade 3D printers are affordable and ubiquitous, while CNC machines demand significant capital and expertise. Desktop 3D printers start at a few hundred dollars; even basic CNC systems require five-figure investments.

However, for metal prototypes, the cost gap narrows. Industrial metal additive manufacturing (AM) systems rival CNC machines in price, with both requiring specialized infrastructure. When outsourcing to a manufacturing partner like Samshion, clients focus solely on part costs—not equipment overhead.

So, is there a stark price difference between CNC-machined and 3D-printed metal prototypes? Not necessarily. Modern CNC machining achieves remarkable efficiency, enabling fast, high-volume production. Meanwhile, metal AM remains a premium solution due to material and energy costs.

Thus, while budget matters, it shouldn’t dictate your choice. Consider factors like design complexity, lead time, and material properties to optimize outcomes.

Advantages of CNC Machining for Metal Prototypes

CNC machining is a proven manufacturing method for producing high-performance metal components across industries like aerospace, automotive, and medical. Renowned for its reliability, it serves both prototyping and full-scale production, with global machine shops delivering visual models, functional prototypes, and end-use parts.

Key benefits include exceptional part strength, scalability for volume transitions, and precision tolerances (±0.025 mm), making CNC a preferred choice over additive manufacturing for applications demanding structural integrity and repeatability.

Mechanical Properties

CNC machining and additive manufacturing (AM) transform metal through fundamentally distinct methods. While processes like Direct Metal Laser Sintering (DMLS) construct parts layer by layer from fused powder, CNC removes material from a solid metal billet.

AM can produce robust prototypes, but CNC offers superior mechanical integrity. The homogeneous structure of machined billets eliminates layer adhesion weaknesses, ensuring consistent density and minimal internal flaws. This results in prototypes with higher tensile strength, fatigue resistance, and dimensional stability—critical for aerospace, automotive, and load-bearing applications.

Scalability

For ultra-low volumes (1–5 units), AM may edge out CNC in cost and speed due to minimal setup requirements, despite longer print times. However, beyond small batches, CNC becomes exponentially more efficient.

This scalability advantage has strategic implications: CNC-machined prototypes streamline the transition to mass production, as tooling and workflows remain consistent. In contrast, AM prototypes often require redesign for traditional manufacturing, adding time and cost. Thus, even if AM saves money for initial prototypes, CNC proves more economical long-term for projects anticipating scale.

Tight Tolerances

CNC machining consistently outperforms 3D printing in precision, enabling metal prototypes to achieve significantly tighter tolerances.

CNC machining can maintain tolerances as precise as ±0.025 mm, whereas even advanced metal 3D printers typically reach only ±0.200 mm. Additionally, CNC ensures exceptional repeatability across production runs—critical not only for mass manufacturing but also for creating multiple prototypes requiring consistent mechanical testing and validation.

Advantages of AM for Metal Prototypes

While CNC machining often delivers superior metal prototypes for scalable production, additive manufacturing (AM) offers unique benefits that make it indispensable for specific applications.

Speed and Cost for Single Units

For urgent prototyping needs with tight deadlines, AM outpaces CNC machining. With minimal setup requirements, metal 3D printers can produce and deliver parts within 2–5 days, bypassing CNC’s tooling and fixturing delays. This makes AM ideal for rapid concept validation or functional testing of one-off designs.

Complex Internal Geometries

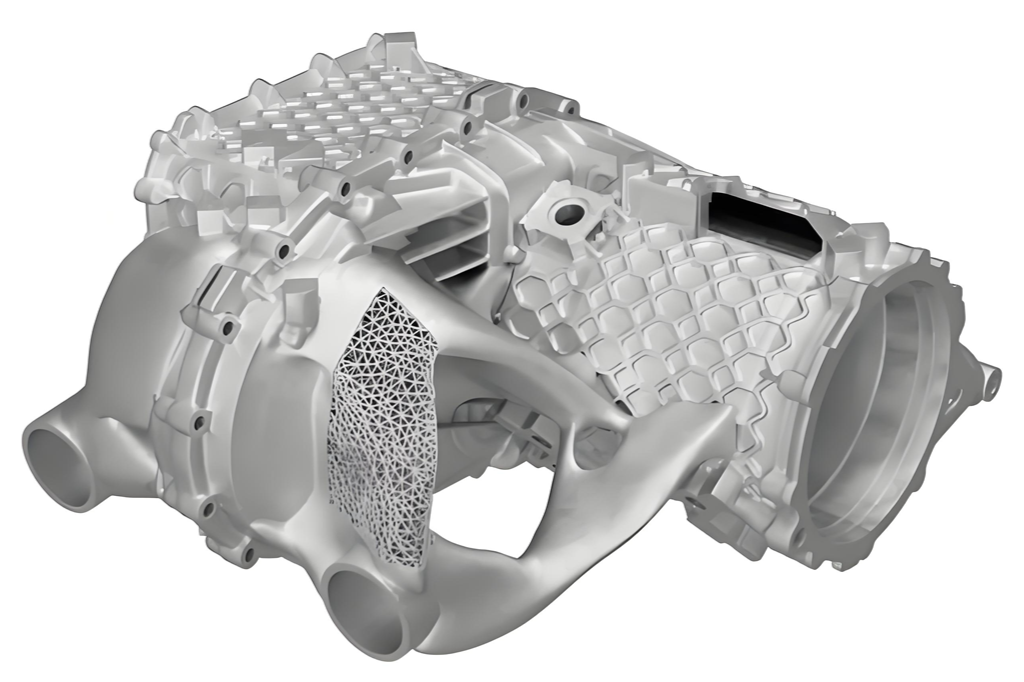

AM excels at creating intricate shapes, including hollow structures, lattice networks, and internal channels—designs unachievable with subtractive methods.

CNC tools cannot access enclosed spaces without altering external surfaces, limiting geometric freedom. AM, however, builds parts layer by layer, enabling unrestricted internal complexity without compromising structural integrity.

When to Choose CNC Machining

High-Strength Requirements: Prototypes demanding structural integrity (e.g., aerospace brackets, engine components).

Tight Tolerances: Applications needing precision within ±0.025 mm (e.g., medical implants, precision gears).

Volume Scalability: Projects anticipating future mass production (1–1,000+ units).

Rounded Features: Designs with complex radii or smooth edges (e.g., automotive housings).

Material Diversity: Prototypes requiring metals like titanium, stainless steel, or copper alloys.

When to Choose Additive Manufacturing (AM)

Low Volumes: One-off or small-batch prototypes (1–10 units) with minimal geometric constraints.

Internal Complexity: Designs with enclosed lattices, conformal cooling channels, or hollow structures.

Urgent Deadlines: Rapid delivery (3–7 days) for concept validation or functional testing.

Lightweighting: Topology-optimized parts for weight-sensitive applications (e.g., drones, robotics).

Cost-Effective Iteration: Frequent design changes without retooling expenses.

Still Unsure?

If your project straddles both technologies, consult a Samshion manufacturing expert. We analyze your design, material needs, and timeline to recommend the optimal process—ensuring prototypes align with performance and budgetary goals.