Introduction – Why PA6 and PA66 Matter in CNC Prototyping

In the world of CNC prototyping plastics, Polyamide (Nylon) reigns supreme. Specifically, PA6 and PA66 are the “workhorse” materials for engineers who need to bridge the gap between a digital CAD model and a high-performance physical part.

Why PA6 and PA66 Are the Go-To Materials for CNC Prototypes

Nylon is favored in nylon CNC machining because it offers a unique combination of high mechanical strength, excellent wear resistance, and significant thermal stability. Unlike softer plastics like PE or PP, PA6 and PA66 maintain their structural integrity under stress, making them ideal for functional testing rather than just aesthetic models.

Typical Applications of PA6 and PA66 CNC Prototypes

You will find these materials used extensively in:

Mechanical Parts: Bearings, bushings, and rollers where low friction is required.

Fixtures & Tooling: Custom jigs that need to be durable yet non-marring to metal workpieces.

Housings: Protective enclosures for electronics or industrial equipment.

Gears: High-torque plastic gears that require impact resistance and self-lubricating properties.

Save Time and Cost by Choosing the Right Nylon Early

Choosing between PA6 and PA66 during the initial prototyping phase is critical. While they appear similar, their differences in moisture absorption and machinability can drastically impact your prototype iteration time. Selecting the wrong grade can lead to unexpected warping or dimensional inaccuracies, forcing expensive re-runs.

Getting the material right on the first “rev” ensures your functional testing yields reliable data for mass production.

How Do PA6 and PA66 Compare in Key Mechanical Properties?

Samshion’s Quality Manager, Jeff Zhu, pointed out that when moving from a CAD model to a functional CNC prototype, the choice between PA6 and PA66 usually comes down to the mechanical limits of the part. While both are “Nylons,” their performance under stress and heat differs significantly. Below, we will analyze it based on its properties.

Comparison Table of Technical Specifications

The following values represent typical properties for unreinforced (neat) extruded grades used in CNC machining.

| Property | PA6 (Nylon 6) | PA66 (Nylon 66) | Impact on Prototype |

| Tensile Strength | ~70 MPa | ~85 MPa | PA66 handles higher loads. |

| Hardness (Rockwell R) | 110 – 115 | 115 – 120 | PA66 is more scratch-resistant. |

| Impact Resistance | Higher (Tougher) | Moderate | PA6 is better for “drop tests.” |

| Wear Resistance | Excellent | Superior | PA66 lasts longer in friction gear apps. |

| Heat Deflection (HDT) | ~65°C | ~90°C | PA66 stays rigid at higher temps. |

| Moisture Absorption | 2.5% – 3.0% | 2.0% – 2.5% | PA6 swells more in humid conditions. |

Prototype Relevance: Which Properties Matter Most?

In the context of CNC prototyping plastics, you shouldn’t just pick the “strongest” material. You should pick the one that validates your specific design goals:

Dimensional Stability (Moisture & Heat): Nylon is hygroscopic (it breathes in water). If your prototype has tight tolerances or must fit into an assembly, PA66 is safer because it absorbs slightly less moisture and has a higher HDT, meaning it won’t “move” as much during or after machining.

Snap-Fits and Living Hinges: If your CNC prototype includes clips or components that need to bend without breaking, PA6 is the better choice. Its lower crystallinity makes it more ductile and less likely to snap under a single high-impact event.

Bearing and Wear Surfaces: For prototypes of gears, cams, or sliding bushings, PA66 is the industry standard. Its higher surface hardness reduces the “break-in” wear and provides a more accurate representation of how a final injection-molded part will perform over thousands of cycles.

Machining Accuracy: Because PA66 is stiffer, it resists the “pushing” force of the CNC cutting tool better than the softer PA6. This often results in more predictable tolerances on thin-walled features.

How to Achieve Dimensional Stability & Tight Tolerances in Nylon Prototypes?

Achieving precision in nylon CNC machining is a different challenge than machining metals. Because nylon is a “living” material—reacting to temperature and humidity—dimensional stability is the most critical factor in a successful prototype.

The following is an account by Benny, Technical Director at Samshion Rapid, of the subtle differences he discovered during actual production between two similar materials in CNC machining.

Moisture Absorption: The Invisible Variable

The biggest difference between PA6 vs PA66 in a workshop is how they “breathe.” Nylon is hygroscopic, meaning it absorbs water from the air, which causes the material to swell.

PA6 (Nylon 6): Absorbs more moisture (up to 3.0% at saturation). A part machined to perfect specs in a dry morning might be out of tolerance by a humid afternoon.

PA66 (Nylon 66): Absorbs less moisture and does so more slowly. This makes PA66 the superior choice for prototypes that must maintain a precise fit over time.

The Samshion Advantage: We maintain a climate-controlled facility and store our nylon stocks in humidity-optimized environments. This ensures that the material we machine today stays consistent with the dimensions you need tomorrow.

Warping Risks During Machining

Nylon carries internal stresses from the extrusion process. When you remove material with a CNC tool, these stresses are released, which can cause the part to “move” or bow.

Thermal Expansion: Nylon has a high thermal expansion coefficient. If the part gets too hot during cutting, it expands; once it cools, it shrinks.

Stress Management: To prevent the “banana effect” (warping), Samshion Rapid utilizes a multi-stage machining strategy. We perform roughing cuts on all sides to release internal stresses, allow the material to “rest,” and then perform final finishing passes for maximum flatness.

Realistic Tolerances for CNC Nylon Prototypes

Designers often apply “metal standards” to plastic parts, which can lead to unnecessary costs. Our team helps customers find the “sweet spot” between precision and physics.

| Feature Type | Standard Samshion Tolerance | High Precision (On Request) |

| General Dimensions | ±0.15 mm | ±0.10 mm |

| Hole Diameters | ±0.10 mm | ±0.05 mm |

| Flatness (per 100mm) | 0.20 mm | 0.10 mm |

Why ±0.05 mm is Better Than Chasing ±0.01 mm

While our high-end CNC centers can move in increments of ±0.005 mm, nylon itself will not stay that still. Chasing a ±0.01 mm tolerance on a nylon part is often a wasted effort because:

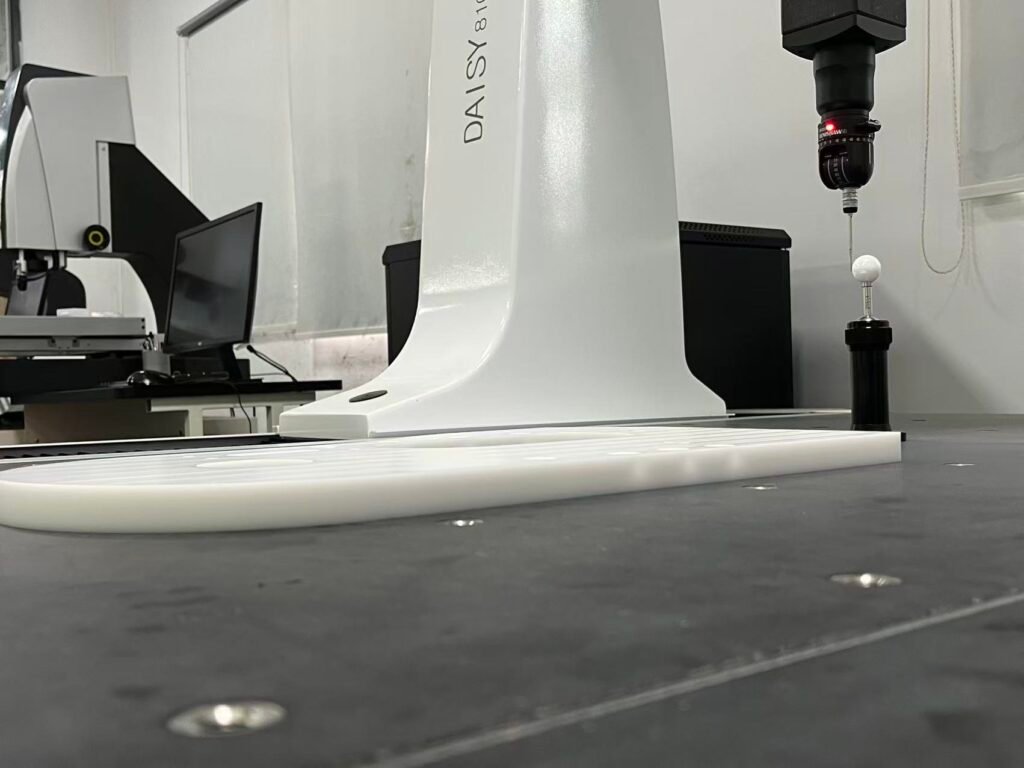

Measurement Sensitivity: The pressure of a digital caliper can actually deform the nylon surface, giving a false reading.

Environmental Shift: A part that measures ±0.01 mm in our inspection room may shift slightly once it reaches a different climate.

Cost Efficiency: Reaching for ±0.01 mm requires significantly more time for cooling and specialized tooling.

Samshion recommends designing for ±0.05 mm. This ensures a functional, repeatable part that balances high precision with the rapid turnaround times our clients expect.

Should You Choose PA6 or PA66 for Your Specific Prototyping Scenario?

Best Choice for Fit-Check Prototypes

When your primary goal is to verify assembly, spatial constraints, or ergonomic feel, the material’s peak performance is less critical than its availability and ease of processing.

PA6 Advantages:

Cost-Efficiency: PA6 is generally more affordable than PA66, making it the ideal choice for early-stage “disposable” prototypes.

Surface Aesthetics: PA6 often yields a slightly smoother “as-machined” surface finish, which is helpful when presenting a concept to stakeholders.

Impact Resilience: If your fit-check involves snapping parts together repeatedly, PA6’s superior toughness prevents the tabs from snapping off during testing.

Best Choice for Functional & Load-Bearing Prototypes

If your prototype is heading to a test lab to be bolted into an engine, pressurized, or subjected to constant mechanical cycling, the “stronger sibling” is required.

PA66 Advantages:

Creep Resistance: Under a constant load, PA66 resists “flowing” or deforming better than PA6. This is vital for threaded inserts or bolted assemblies.

Thermal Stability: For prototypes operating near heat sources (like automotive under-the-hood components), PA66’s higher melting point (~260°C) ensures the part remains rigid where PA6 might soften.

Hardness: PA66 provides a more realistic simulation of a final injection-molded part’s wear characteristics.

Short-Run Prototype vs. Bridge Production

Transitioning from a single prototype to a small batch (10–100 units) requires a shift in mindset. This is where Samshion Rapid’s bridge production expertise comes into play.

Scalability: PA66 is often preferred for bridge production. Why? Because most high-performance injection-molded products are designed for PA66. Using the same material for your CNC-machined small batch gives data that closely mimics the final mass-produced part.

Consistency: For small batches, PA66’s lower moisture absorption means that part #1 and part #50 are more likely to stay within the same tolerance band during shipping and storage.

The Hybrid Approach: In some cases, we recommends PA6 (Cast) for very large-scale bridge prototypes because cast nylon has lower internal stress, reducing the risk of warping across a batch of 50+ large units.

What Are the Common Mistakes to Avoid When Machining Nylon?

Samshion’s president, Reid, based on years of experience, stated that even with the highest grade of PA6 or PA66, a prototype can fail if the machining process doesn’t account for the unique “behavior” of polymers. We often consult with clients to correct these four common industry mistakes:

1. Ignoring Moisture Conditioning

Nylon is “hygroscopic”—it acts like a sponge. A common mistake is machining a part to perfect dimensions in a bone-dry environment without considering that the part will swell as it absorbs ambient humidity.

The Result: A bearing that fit perfectly at the factory becomes too tight to rotate once it reaches the customer.

Our Fix: We calculate “post-machining growth” and, for critical applications, we pre-condition the raw material to a stabilized moisture level before the final pass.

2. Over-Tight Tolerances

Many designers copy-paste tolerances from steel or aluminum drawings (e.g., ±0.01 mm) onto nylon parts.

The Result: Skyrocketing costs and high scrap rates. Because nylon expands with the heat of a person’s hand or a change in room temperature, holding “metal-grade” tolerances is often physically impossible.

Our Fix: We suggest functional tolerances (typically ±0.05 mm to ±0.1 mm). If you truly need tighter fits, we utilize press-fit inserts or oversized machining followed by a “settling” period.

3. Wrong Tool Geometry

Using standard end mills designed for steel is a recipe for disaster. Nylon requires extremely sharp edges and high rake angles.

The Result: Dull tools “push” the material rather than cutting it, leading to “fuzz” on the edges, melting, and poor surface finish.

Our Fix: We use polished-flute, single-edge cutters specifically designed for plastics. These tools evacuate chips rapidly to prevent heat buildup, ensuring the crisp edges seen in our high-quality prototypes.

4. Treating Nylon Like Metal

Nylon has a low modulus of elasticity, meaning it is flexible. If you clamp it in a standard CNC vise with the same force used for a block of aluminum:

The Result: The material deforms under clamping pressure. You machine a perfect hole, but when you release the vise, the part “springs back” and the hole becomes an oval.

Our Fix: We use custom soft jaws and vacuum fixtures to distribute clamping pressure evenly, ensuring the part remains stress-free during the entire machining cycle.

How Does Samshion Rapid Machine Nylon Prototypes Faster?

At Samshion Rapid, we bridge the gap between complex engineering and fast delivery. We understand that a prototype delayed is a product launch delayed.

Plastic-Specific CAM Strategies: Our programmers use high-speed “trochoidal” milling paths that keep the tool engaged for less time, reducing heat and allowing us to push the machine faster without melting the PA6/PA66.

Dedicated DFM Review: We don’t just take your file and hit “start.” We analyze your nylon design for wall thickness and stability, providing feedback that prevents warping.

Rapid Turnaround: By maintaining a consistent stock of high-quality extruded PA6 and PA66, we eliminate supply chain lag.

Accelerate your development: Most of our nylon CNC projects fall within our optimized 3-day CNC prototyping timeline, allowing you to test, fail, and succeed faster than the competition.

Conclusion – Choosing the Right Nylon for CNC Prototyping

Whether you choose PA6 for its impact toughness and cost-efficiency or PA66 for its superior heat resistance and strength, the success of your prototype depends on the expertise behind the machine.

Choosing the right nylon early in the design phase prevents costly iterations and ensures your functional tests are accurate. If you are unsure which grade is right for your specific mechanical load or environment, our team is here to help.

Ready to bring your Nylon design to life? Don’t let material selection hold up your project. Upload your CAD files today for a free DFM review and a quote. Whether it’s a single fit-check component or a bridge-production run, Samshion Rapid delivers precision PA6 and PA66 parts in as little as 3 days.