EDM Electrode Manufacturing: Materials, Techniques & Best Practices Guide

Electrical Discharge Machining (EDM) has cemented its position as a cornerstone technology in modern manufacturing, enabling the production of intricate geometries and high-precision components that are often difficult or impossible to machine with conventional methods. Central to EDM’s effectiveness is the precise manufacturing of electrodes, which serve as the “tool” that delivers controlled electrical discharges […]

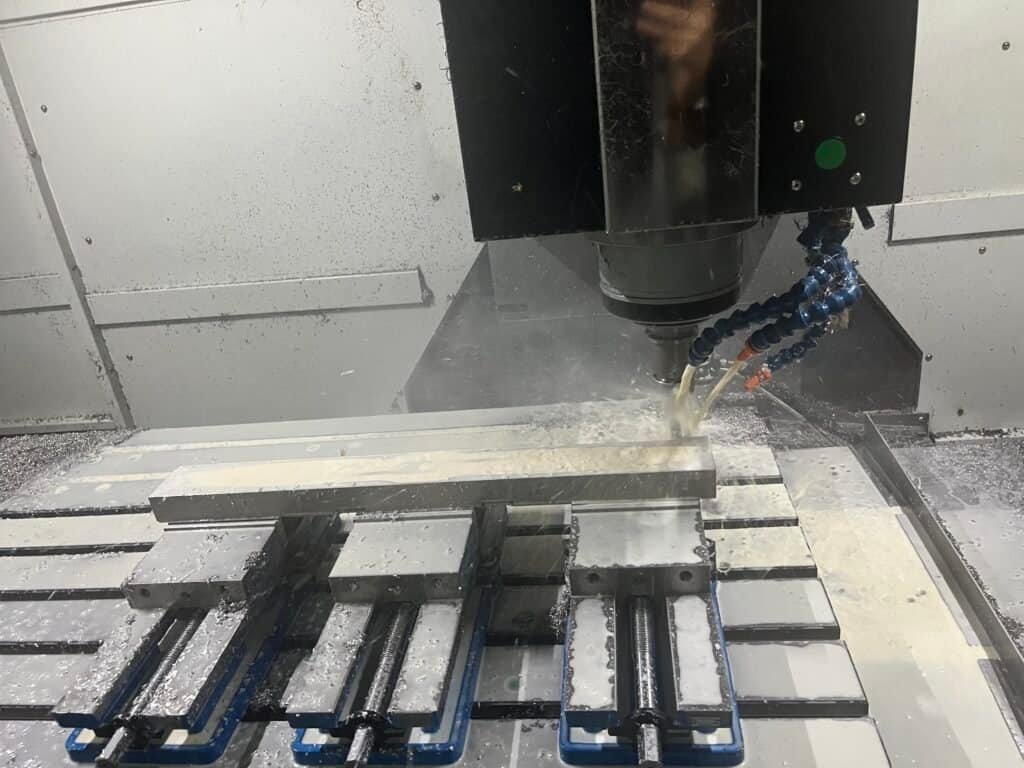

POM CNC Machining Playbook: Speeds, Feeds & Stress Relief for Warp-Free Parts

Polyoxymethylene (POM), also known as acetal, polyacetal, and polyoxymethylene, is one of the most widely used engineering plastics in CNC machining components. Due to its excellent mechanical strength, dimensional stability, low friction, and chemical resistance, POM has gained a good reputation in the automotive, electronics, medical, and consumer goods industries. Over the past twenty years, […]

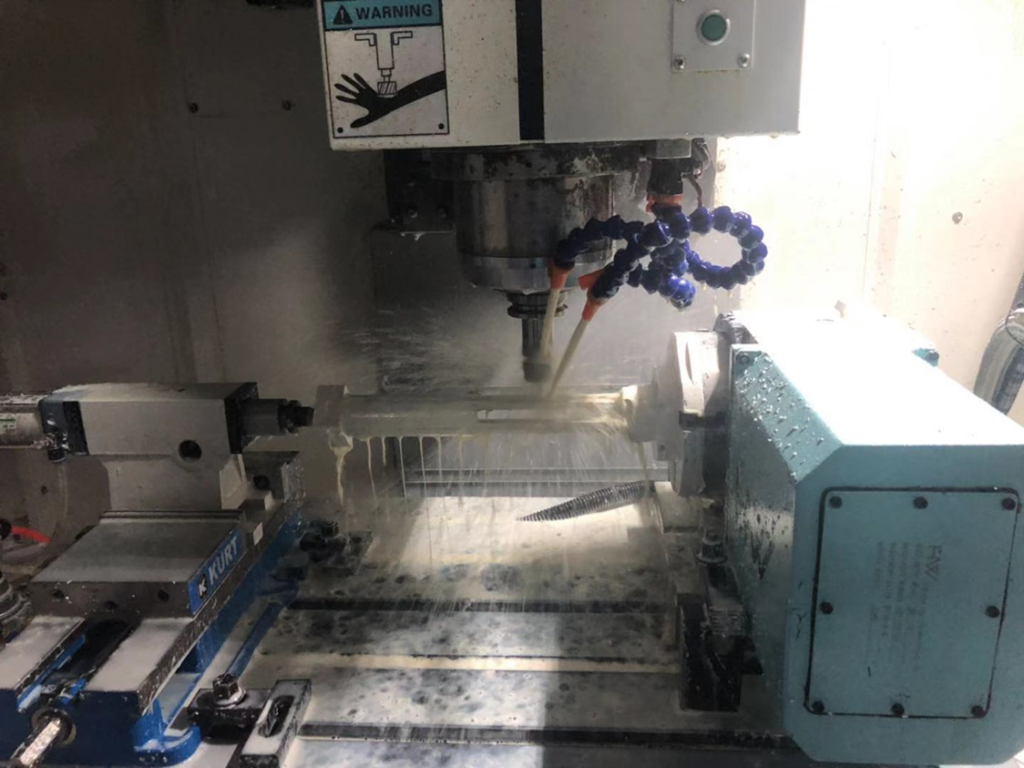

Titanium CNC Machining: Mastering the Unmachinable & High-Efficiency Blueprint

Titanium CNC machining has become a cornerstone of modern high-performance manufacturing. With industries such as aerospace, defense, automotive, medical, and electronics increasingly demanding components that are lighter, stronger, and more durable, titanium has established itself as a material of choice for mission-critical applications. Its high strength-to-weight ratio, corrosion resistance, biocompatibility, and mechanical stability under extreme […]

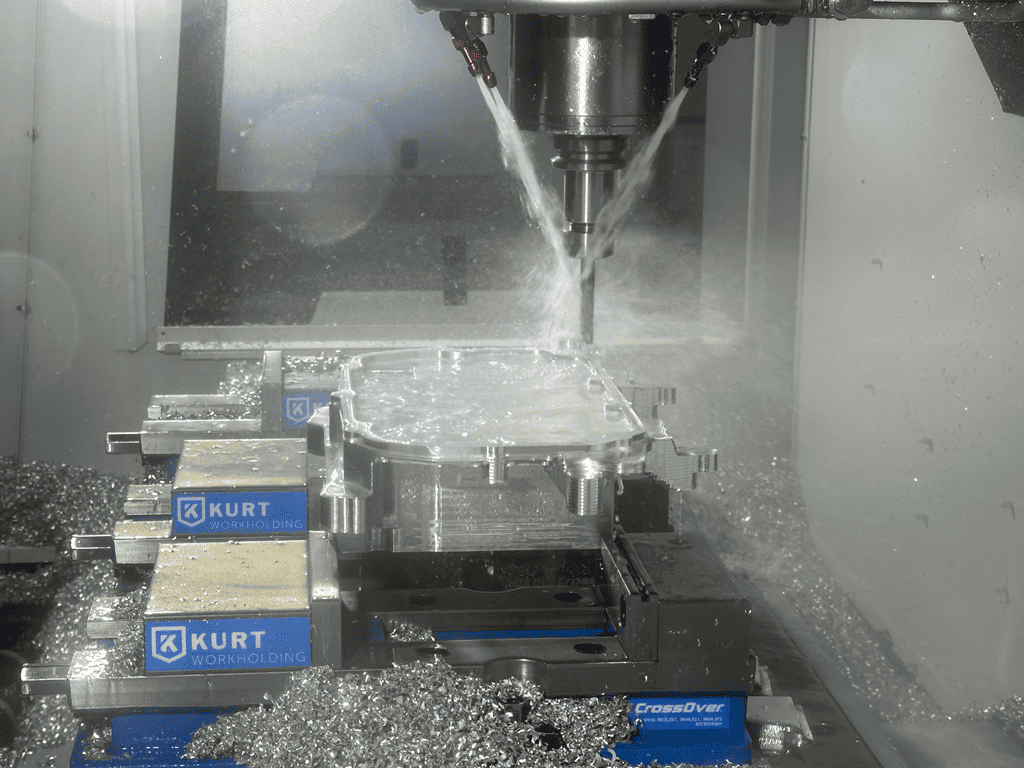

Machining Hardened Tool Steel: Advanced CNC Strategies for High-Performance

Introduction: Navigating the Challenges of Precision Machining for Hardened Tool Steels Hardened tool steel represents one of the most demanding materials in precision CNC machining, combining exceptional hardness, wear resistance, and thermal stability that push conventional machining technologies to their limits. With hardness levels typically ranging from 45–68 HRC, these materials require specialized tooling strategies, […]

How to Reduce CNC Milling Vibration: 12 Expert Strategies

In CNC milling, cutting vibration—commonly known as chatter—is one of the most persistent and critical issues that machinists and manufacturing engineers face. Vibration not only compromises machining accuracy and surface finish, but also significantly shortens tool life and increases wear on the spindle and machine components. In severe cases, chatter can cause tool breakage, poor […]

An In-Depth Overview of Reamers: Classification, Applications, and Design Principles

Over years of supporting global customers in CNC machining and precision tooling, the Samshion team has accumulated extensive hands-on experience with reamers, hole-finishing processes, and tolerance control. In actual production—whether dealing with small-batch prototypes or high-volume precision components—we consistently observe that the correct choice of reamer type, reaming allowance, cutting parameters, and tool material directly […]

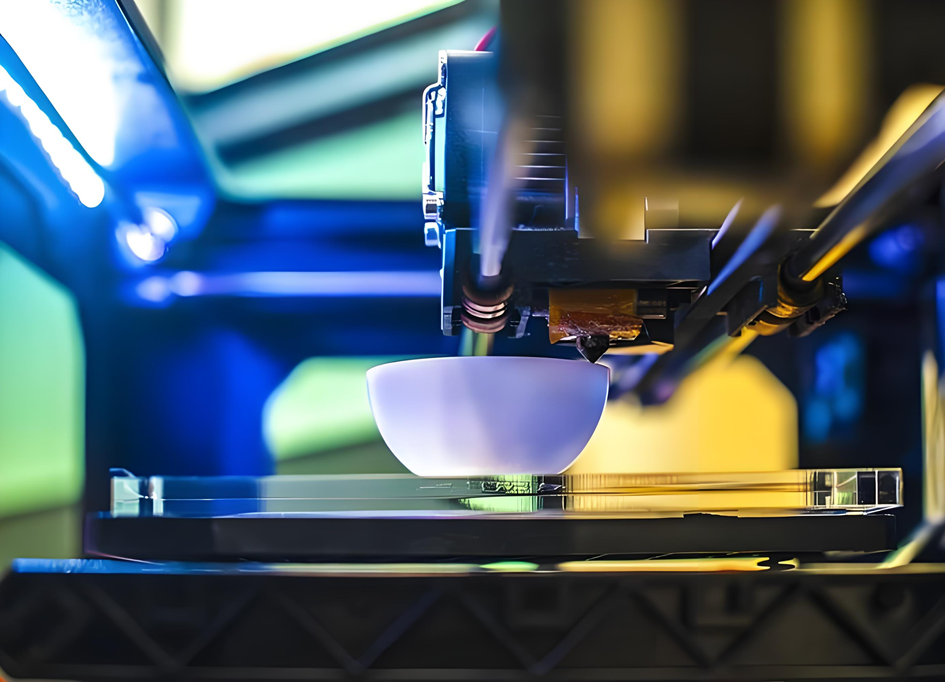

The 3D printing process: How an idea becomes a precise component

3D printing has long since become more than just a tool for prototypes or one-off productions. A growing number of companies, including Samshion, are integrating additive manufacturing as a complementary process into their production. However, to produce components consistently and to a high standard, a deep understanding of the entire 3D printing process is crucial […]

Commonly Misapplied CNC Features: How Engineers and Operators Can Identify and Avoid Inefficiencies in CNC Operations

CNC machining centers and turning centers are used for countless applications, which is why almost every manufacturer has these machines in their shops. Paralleling company diversity is the wide spectrum within each utilization factor: Lot size – At one end of the spectrum are companies that regularly run under 10 workpieces per lot. At the […]

Vertical vs Horizontal Milling: Which Is Best for Your CNC Project?

At Samshion Rapid, our engineers and machinists rely daily on both vertical and horizontal milling systems to produce high-precision metal parts for industries ranging from automation to tooling and custom product development.Through years of CNC production experience, our team has gained a deep understanding of how the structure and motion of each milling type — […]

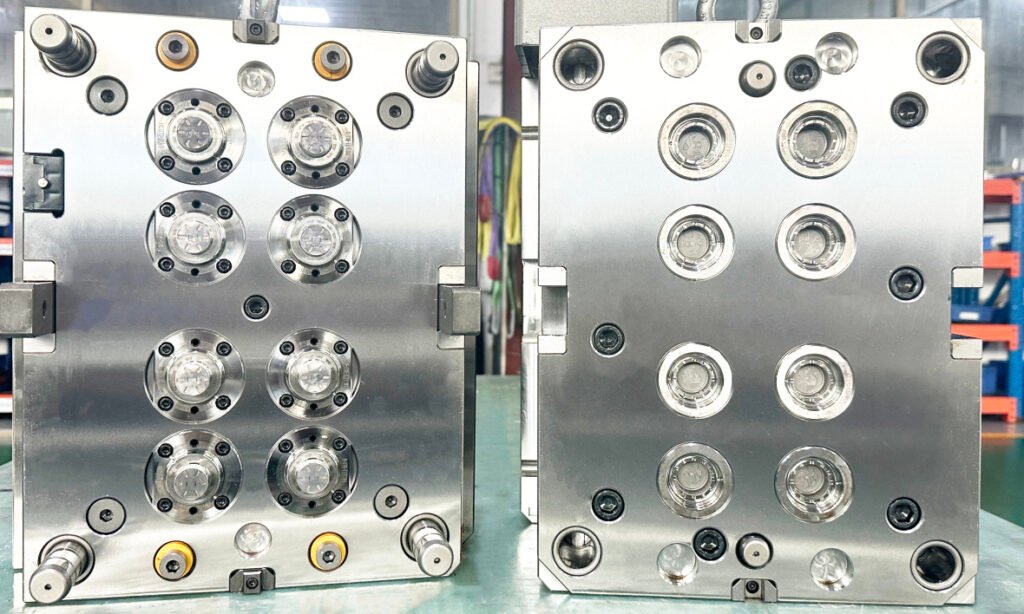

Why Cheap Injection Molds Cost More: The Hidden Expenses

A Comprehensive Technical and Economic Analysis by Samshion Rapid Executive Summary The cost of an injection mold is often the first and most visible figure in any plastic product development budget. However, the true economic value of a mold cannot be determined solely by its upfront price. The real costs are distributed throughout the mold’s […]