Case Studies

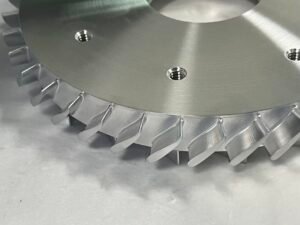

At Samshion, our team of engineers and designers partners with innovators worldwide—from startups to Fortune 500 leaders—to craft high-performance prototypes and precision components. We serve industries like automotive, aerospace, medical devices, and consumer tech, transforming blueprints into reality through advanced technologies like CNC machining, vacuum casting, and 3D printing.

Speed and agility define our approach. Whether testing market viability with low-volume batches or validating mass production via rapid tooling and die casting, we empower clients to iterate faster, reduce risks, and scale confidently.

Below, explore how we’ve delivered solutions for complex challenges across industries—detailing materials, processes, and outcomes.

The “Tolerance Stack-up” Nightmare: Why Your CNC Prototypes Don’t Fit Together

Introduction: When Perfect Parts Refuse to Assemble I believe as customers, you may have encountered similar ‘nightmares’. You have received

CNC Fixturing & Setup: Why Low-Volume Prototyping Costs So Much Compared to Mass Production?

Introduction: The Cost Paradox in CNC Manufacturing For many hardware startups and procurement managers, the first quote for a custom

Cost-Efficient PEEK Prototyping: Key Considerations for CNC Projects

What is PEEK and Why Does It Pose Unique Machining Challenges? We often receive inquiries from engineers asking why a

CNC Machining PA6 vs. PA66: Prototyping Guide and Technical Parameters

Introduction – Why PA6 and PA66 Matter in CNC Prototyping In the world of CNC prototyping plastics, Polyamide (Nylon) reigns

Rapid CNC Prototyping: How to Get Parts in 3 Days (Timeline)

Why Speed Matters in CNC Prototyping? In the high-stakes world of product development, the difference between a market leader and

Cast Iron CNC Machining: Achieving Precision & Controlling Wear

A Technical White Paper on Stability, Tooling, and Quality Control Executive Summary Despite the maturity of modern CNC technology, achieving