A Comprehensive Technical and Economic Analysis by Samshion Rapid

Executive Summary

The cost of an injection mold is often the first and most visible figure in any plastic product development budget. However, the true economic value of a mold cannot be determined solely by its upfront price. The real costs are distributed throughout the mold’s lifetime—spanning design, machining, assembly, production, maintenance, and eventual retirement.

This paper examines, in detail, why inexpensive injection molds frequently result in higher total ownership costs for manufacturers. While the initial investment appears low, these molds often introduce hidden expenses: reduced mold life, increased scrap rates, longer cycle times, higher downtime, poor material compatibility, and limitations in automation integration.

Drawing on over 15 years of tooling experience, Samshion Rapid outlines how mold quality, steel selection, thermal management, and precision machining influence both productivity and part cost. Through practical engineering examples and cost modeling, this document demonstrates that choosing the right mold is not a question of “how much it costs today,” but rather “how efficiently it performs tomorrow and how consistently it pays back over its operational life.”

How Can We Understand the Hidden Economics of Molding?

For most buyers considering injection molding, the very first question is always:

“How much does the mold cost?”

That’s completely understandable—after all, tooling is usually the largest upfront investment in plastic part production.

But there is a hidden risk: if you only focus on the initial mold price and ignore other key factors, in the long run, you may end up paying more fees. At first, seemingly cheaper molds can quickly turn into higher production costs, such as unexpected downtime or even comprehensive repairs.

In practical terms, injection molds are capital assets, not consumables. They are expected to deliver consistent parts over tens or hundreds of thousands of cycles, often operating under harsh mechanical and thermal conditions. Evaluating a mold’s economic performance, therefore, requires a total cost of ownership (TCO) approach—considering factors such as:

1.Tool steel grade and heat treatment

2.Dimensional stability and precision of cavity machining

3.Cooling channel design and heat transfer efficiency

4.Mold maintenance accessibility and part replacement design

5.Automation readiness and integration with molding cells

6.Expected mold lifetime in terms of validated cycle counts

A low-cost mold that lacks these engineering optimizations might save 20–30% at purchase, but can easily increase per-part cost by 50–100% during its production life.

Let’s break down the key factors beyond upfront cost that truly determine whether your mold investment saves money—or silently drains it.

Mold Lifetime – How Long Will the Tool Really Last Before Replacement?

At Samshion Rapid, our engineering team often encounters this exact scenario when evaluating customer tooling requests. In many cases, we find that molds designed purely to minimize initial cost ultimately fail to deliver consistent output or efficiency across production runs. A mold’s lifetime determines how many cycles it can run before major repairs or replacement.

A “cheap” mold made with low-grade steel might only last for 100,000 shots, while a properly hardened mold with higher-grade steel could last well beyond 1 million cycles.

1. The Relationship Between Steel Selection and Tool Life

The steel grade is the most decisive factor in determining mold durability. Inexpensive molds often use P20 pre-hardened steel (28–32 HRC) or even aluminum alloys (7075-T6) for rapid tooling. These materials are suitable for low-volume runs or prototype molds but are not designed for continuous production.

By contrast, DIN 1.2344, DIN 1.2083, or 420 SUS tool steels—when vacuum-hardened to 48–52 HRC—offer exceptional wear and corrosion resistance, supporting millions of molding cycles without dimensional drift.

When manufacturers attempt to save costs by using soft or uncoated steel, they often encounter early wear at the parting line, gate area, and ejector pin locations—leading to flash, burn marks, and ultimately, rework or full mold replacement.

2. Tool Life Cost Calculation Example

Consider a production requirement of 500,000 parts.

1.A low-cost mold using P20 steel might last only 100,000 cycles before dimensional degradation.

2.A high-quality mold using hardened H13 steel might last 1,000,000 cycles or more.

This means the cheaper mold must be replaced five times to meet the same output.

If the initial cheap mold costs $15,000, total mold spending over the project becomes $75,000, excluding downtime, setup, and re-qualification.

A premium mold costing $35,000 initially could complete the same volume with consistent part quality, ultimately saving over $40,000 in hidden replacement and downtime costs.

3. What Are the Downtime and Requalification Losses?

Each mold replacement involves downtime, machine idling, quality revalidation, and potential scrap during setup. For automotive or medical component production, every revalidation requires formal PPAP (Production Part Approval Process) or IQ/OQ/PQ qualification. These processes can cost thousands of dollars and cause weeks of delay.

The real cost is not what you pay for the mold, but how long it serves you.

4. The Role of Heat Treatment and Surface Coating

Tool steels must undergo proper heat treatment, stress relief, and polishing. Poor heat treatment can result in internal stresses and cracking, reducing mold lifetime drastically.

For aggressive materials such as glass-filled nylon (PA6+GF30) or PBT, coatings like TiN, TiAlN, or CrN applied via PVD (Physical Vapor Deposition) can extend tool life by reducing friction and wear.

A cheap mold supplier may skip or underperform these processes, resulting in rapid tool degradation. Once wear reaches the cavity area, dimensional accuracy cannot be recovered without costly re-machining.

Precision – Does Saving on Tooling Lead to Higher Scrap?

Low-cost molds often compromise on machining precision. The result is higher scrap rates and inconsistent part quality.

Even a 2–3% increase in scrap rate may seem minor, but in mass production it translates into tens of thousands of wasted parts, plus wasted resin, labor, and machine time.

At Samshion Rapid, our engineering team frequently audits molds from various suppliers and has observed that inadequate cavity accuracy and poor surface finish are the primary causes of these scrap increases.Every percentage point in part quality translates directly into cost. Skimping on precision molds will always cost more than it saves.

1. Why Are Tolerancing and Fit Accuracy Critical?

In injection molding, precision is not optional—it defines the mold’s ability to repeatably produce dimensionally stable parts.

Tolerances in the range of ±0.02 mm to ±0.05 mm are common for technical parts. Achieving this requires CNC machining, EDM finishing, and coordinate measurement inspection (CMM) for validation.

Inexpensive molds often skip precision inspection, leading to cavity mismatch, gate imbalance, or inconsistent venting—all of which result in flashing, sink marks, or short shots.

2. How Do Dimensional Drift and Warpage Affect Quality?

Tool wear, improper mold alignment, and insufficient cooling symmetry contribute to dimensional drift over time.

Precision molds employ guide pillars, leader bushings, and precision dowels (e.g., HASCO standard) to maintain repeatable alignment. They also rely on uniform wall thickness and optimized moldflow analysis to predict and correct warpage before cutting steel.

Low-cost molds skip these analyses, resulting in high rejection rates once mass production starts.

Cycle Time – Why Is Every Second Really Money?

Molding is a numbers game: the faster your cycle time, the more parts you produce per hour. Cooling design and mold materials play a huge role here.

A mold with poor cooling may run at 40 seconds per cycle, while a well-engineered mold with beryllium copper inserts could cut that to 30 seconds. Over 1 million cycles, saving 10 seconds per cycle means nearly 2,777 hours less machine time. Multiply that by your machine’s hourly cost, and the “expensive” mold quickly proves to be cheaper in the long run.

Mold cost is one-time; cycle time affects every single part you produce.

1. The Thermodynamics of Mold Cooling

Injection molding involves repeated cycles of melting, filling, packing, cooling, and ejection. Among these, cooling accounts for up to 60–70% of the total cycle time. The thermal efficiency of a mold depends primarily on the design of its cooling channels, the thermal conductivity of the materials used, and the temperature control system (including water flow, turbulence, and mold temperature controllers).

Poorly designed or shallow cooling channels lead to uneven temperature distribution, localized hot spots, and extended cooling time. These issues not only lengthen each molding cycle but also cause internal stress, warpage, and shrinkage variation in parts.

A mold engineered with conformal cooling (channels following the shape of the cavity, often 3D printed in tool steel or hybrid Cu alloys) can reduce cycle times by 20–40% while maintaining part quality. Though this increases the initial cost by 15–25%, the return on investment is typically achieved within the first few months of production.

2. Material Influence and Heat Transfer

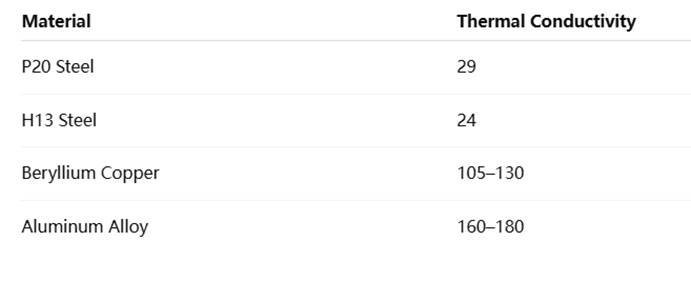

Different tool materials have vastly different thermal conductivities (W/m·K):

Strategic use of high-conductivity inserts (beryllium copper or aluminum bronze) in regions like the core or gate area can drastically shorten cooling times. However, these inserts must be engineered carefully to avoid galvanic corrosion or bonding failure when combined with steel components.

Maintenance & Repair -Why ls Downtime More Expensive than Tooling?

Cheap molds often have integrated designs that are difficult to repair. When a small part wears out, the entire tool might need to stop production for extended maintenance.

A better-designed mold with replaceable inserts may cost more initially, but when wear occurs, you can simply swap out the insert in hours instead of stopping production for days or weeks. At Samshion Rapid, our mold maintenance engineers emphasize modular and serviceable mold structures in every design stage.

Every hour of downtime costs more than most customers realize. Investing a bit more in maintainable molds saves money over the long term.

1. What Is the Value of Modular Design?

A modern, well-designed mold is built according to a modular architecture. This means the mold is composed of interchangeable inserts, standardized components (HASCO/DME), and easily removable wear parts such as lifters, sliders or gates.

For example, in a multi-cavity tool, even without disassembling the entire mold base. individual cavity inserts should be detachable. This allows operators to replace a single damaged cavity while the remaining ones continue production, maintaining about 70% uptime.

Low-cost molds typically do not follow this philosophy—they integrate all features into a solid core block, meaning that any failure (even a worn ejector pin hole or chipped gate) requires complete teardown and re-machining.

2. How Does Predictive Maintenance Reduce Costs?

Modern manufacturing facilities integrate IoT-based monitoring systems within injection molds. Sensors can record parameters such as:

Number of cycles completed

Cavity temperature distribution

Cooling channel flow rate

Mold open/close force trends

These data points allow predictive maintenance, ensuring that wear components (e.g., ejector pins, seals, guide bushings) are replaced before failure occurs.

In low-cost tooling, such systems are often omitted, leaving operators to rely on manual inspection and reactive repair—an approach that leads to unexpected breakdowns.

Material Compatibility – How Can Wear & Corrosion Be Minimized?

Plastic resins behave differently under heat and pressure. Some contain glass fibers or flame retardants that are highly abrasive. Others, like PVC, release corrosive gases. Samshion’s materials engineering team conducts detailed resin–steel compatibility analyses before finalizing any mold design. By evaluating factors such as resin composition, filler abrasiveness, and thermal expansion behavior, we select optimal steels and coatings—ranging from H13 and S136 to beryllium copper or P20 variants with surface nitriding.

If the mold is built with the wrong steel, corrosion pits or abrasion marks can appear within months. Frequent re-polishing, lost precision, and premature tool failure follow.

Spending a bit more on the right mold steel avoids costly maintenance cycles and premature retooling.

1. Why Must Designers Understand Resin Behavior?

Injection mold designers must consider chemical, thermal, and mechanical interactions between the resin and mold steel.

For example:

Glass-filled nylons (PA6/PA66 GF30–50%) act like sandpaper, wearing down cavity surfaces quickly.

PVC and POM release acidic gases during processing, causing corrosion if not vented or plated properly.

Polycarbonate (PC) requires high molding temperatures, accelerating thermal fatigue in untreated steels.

For these materials, tool steels like S136, 420SS, or 2083H are recommended for their corrosion resistance and polishability. Additionally, surface treatments like nitriding, chrome plating, or DLC coating can provide an extra layer of protection.

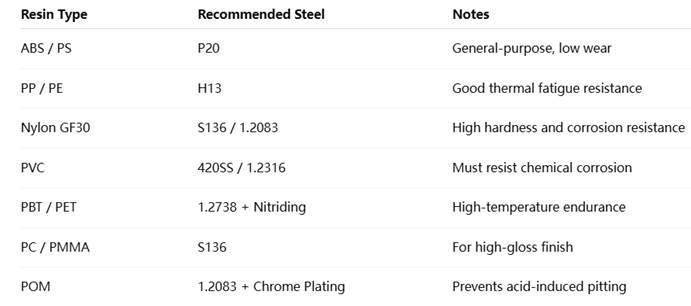

2. Steel Compatibility Reference Table

Choosing the wrong steel grade can shorten tool life by 70–80%, a problem often seen in “budget” molds built without engineering input.

Surface Quality- Why Are Appearance lssues Hard to Fix?

When it comes to aesthetic or high-precision components—automotive interior trims, medical device, electronics shells —surface quality is not negotiable. The visual and tactile quality of a product is usually the primary factor defining brand quality perception. However, the surface smoothness largely depends on the material, precision, and process of the mold itself.

A common misconception is that polishing can fix surface imperfections on low-grade molds. In reality, no amount of polishing can compensate for inferior steel composition, poor machining accuracy, or incorrect heat treatment. Because even after polishing, tiny gaps, inclusions, or tool marks embedded in the soft steel will continue to affect surface replication.

In one real-world case observed by Samshion Rapid, a client used low-carbon tool steel for a mold intended to produce glossy appliance housings. After only a few thousand shots, the surface finish degraded significantly. Microscopic corrosion, combined with resin outgassing, produced dull patches and uneven gloss. The mold had to be rebuilt using hardened stainless tool steel with mirror-finish polish capability—doubling the total project cost.

Certain resins, such as PMMA or polycarbonate, require optical-level finishes (SPI A1 or better). Achieving these finishes demands not only premium mold steel—like S136, NAK80, or SUS H13—but also meticulous polishing under controlled environmental conditions. Low-grade or improperly heat-treated steel cannot achieve such finishes because the microstructure itself lacks the density and hardness uniformity required for fine polishing.

Moreover, surface quality directly affects part release. A poorly finished cavity can lead to sticking, drag marks, or surface blemishes, all of which increase scrap rates. Conversely, a smooth, precise cavity allows consistent part ejection and extends the mold’s operational life.

Investing in surface quality is, therefore, a double win: it enhances the final product’s visual appeal while reducing cycle interruptions and part rejection. And as every experienced molder knows, it is much cheaper to polish the steel once, properly, than to repair surface defects on thousands of parts.

Single-Part Cost – How Do We Measure the True Economic Value of a Mold?

At the end of the day, customers don’t buy molds—they buy molded parts. The true measure of a mold’s economic performance is the cost per finished part it enables.

While mold pricing often dominates early discussions, what ultimately matters is how the tooling, material, maintenance, and process variables combine to determine the single-part cost. This metric captures not just the upfront tooling investment but the entire operational reality of producing each unit.

To illustrate, let’s revisit the example from earlier:

If a mold costs $20,000, and total production expenses—including maintenance, downtime, and labor—amount to $30,000, the total project cost becomes $50,000. If you produce 50,000 parts, then each part effectively costs $1.00.

Now imagine that,due to premature wear, poor cooling, or high scrap rates, the same mold can only produce 40000 high-quality parts before it needs to be replaced. Despite the “cheap” price of the mold, the effective single piece cost has jumped to $1.25 per part, an increase of 25%. On the contrary, the cost of precision designed molds may be $35000, but they can run efficiently 100000 cycles without the need for mold repair, and the cost of each part may be as low as $0.65.

At Samshion Rapid, this kind of analysis is a standard part of project consultation. The engineering team considers variables such as projected production volume, part geometry, plastic type, cycle time, maintenance frequency, and retooling intervals. By modeling these factors, we provide clients with a comprehensive Total Cost of Ownership (TCO) projection—allowing customers to choose suitable production solutions based on their own needs.

This approach demystifies mold pricing and emphasizes performance-based decision-making. It helps clients visualize that an investment in superior tooling is not a cost—it’s a long-term profit strategy.

Conclusion — Long-Term Mold Economics

The question “How much does the mold cost?” is simple, but it’s only the beginning of a much deeper conversation. A truly cost-effective mold is one that maximizes efficiency, consistency, and longevity—reducing the total cost per part over its entire operational life.

Through the lenses of lifetime, precision, cycle time, maintenance, material compatibility, automation readiness, and surface quality, the economics of injection molds become far clearer. Each of these elements interacts with the others; a weakness in one area amplifies costs in another. For example, poor cooling increases cycle time, which in turn raises per-part cost, while insufficient material hardness accelerates wear, increasing maintenance expenses.

The concept of Samson Rapid is rooted in this holistic understanding. Our company’s mission is not just to manufacture molds, but to create more value. By adjusting mold design, material selection, and production strategies, Samson Rapid provides molds with sustainable manufacturing performance and offers predictable cost control plans. With the increasingly fierce competition in the global manufacturing industry, even small inefficiencies can have huge financial consequences. The downtime of losing a few seconds, deviating from the tolerance by a few micrometers or days per cycle can quickly offset any initial savings brought by cheaper molds.

That’s why the smarter question is not:

“How much does the mold cost?”

but rather:

“What will this mold cost per part over its lifetime?”

When manufacturers start asking that question, they begin to see tooling not as an expense, but as an investment in their production future. Cheap molds rarely save money—they merely postpone costs.

A well-engineered mold, on the other hand, pays dividends every day it runs smoothly, efficiently, and reliably.

At Samshion Rapid, we help clients avoid the hidden traps of “cheap tooling” by designing molds that balance cost with performance, scalability, and durability. From prototype to mass production, our engineering team partners with you to calculate real manufacturing economics, ensuring that every mold not only meets but exceeds expectations.

That’s the true definition of value in injection molding.