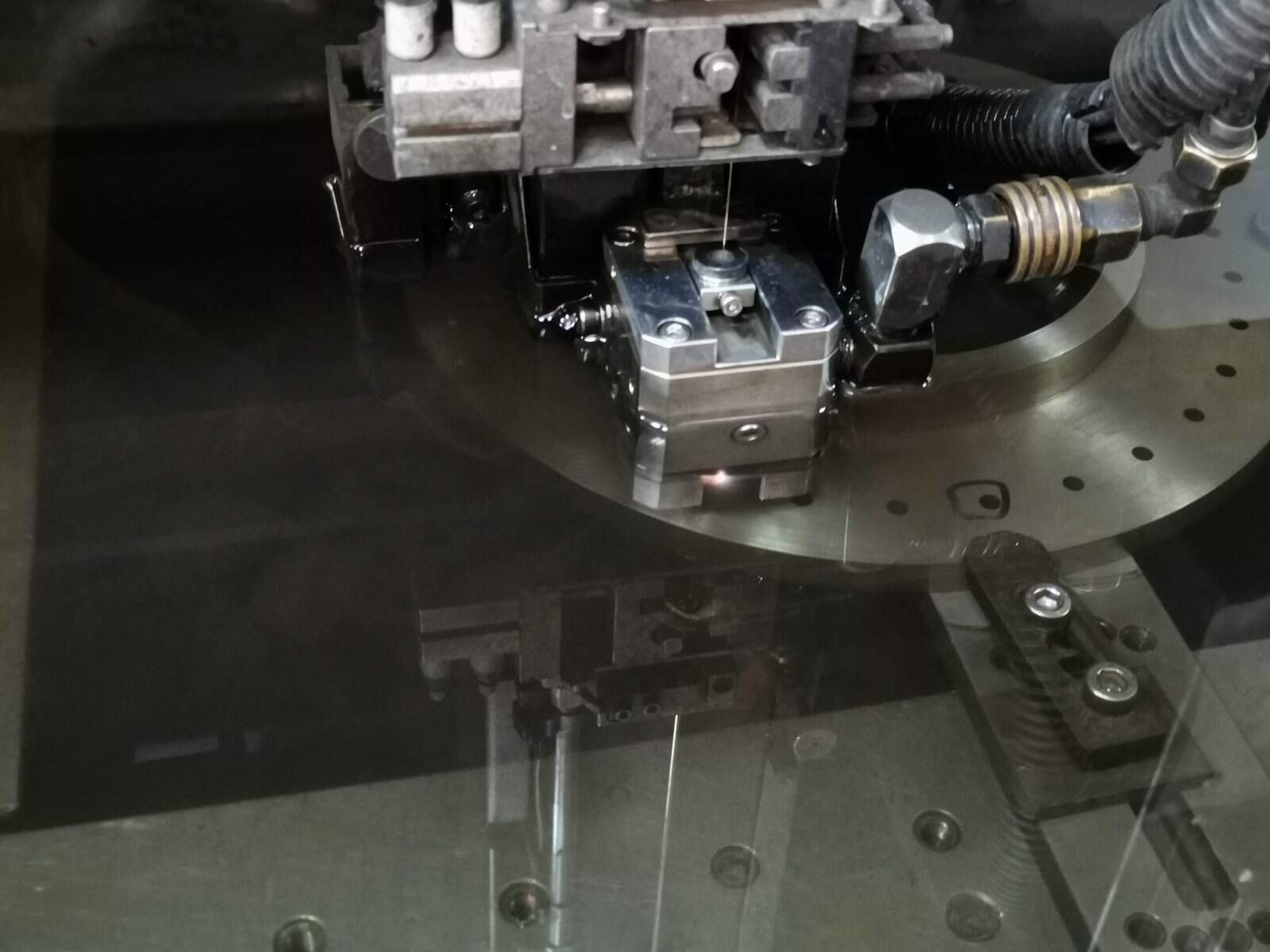

At Samshion Rapid, precision isn’t just a promise—it’s part of our daily workflow. Our EDM machining team, composed of engineers and operators with over 20 years of hands-on experience, consistently pushes the limits of accuracy and efficiency in fine toolmaking and mold manufacturing.

In the field of wire EDM (Electrical Discharge Machining), we often face common challenges such as entry marks, poor corner finishing, part deformation, and dimensional inconsistencies in thick workpieces. Even with advanced machines from Mitsubishi and Sodick, such challenges can occur.Based on years of production experience at Samshion, this article summarizes practical methods our engineers use to solve these problems and ensure stable, high-precision results.

How Can Samshion Eliminate Tool Entry Marks?

Entry marks are small but can ruin the precision or aesthetic of a part. Our team has developed several strategies to avoid visible tool entry marks.

For External Profiles

Samshion’s programmers always apply arc entry and exit paths instead of direct linear approaches. The arc movement distributes discharge energy gradually, preventing concentrated spark erosion that leaves visible tool marks. This kind of techniques produce a seamless transition between cutting start and end points, resulting in smooth surfaces ideal for mold cavities or aesthetic components.

For Internal Holes

1.Start from a corner if possible. For closed holes, our engineers sometimes redesign them as open-ended structures to allow cleaner wire entry.

2.Vary entry positions for multi-pass cutting. Each finishing pass starts at a different point to avoid overlap, minimizing localized burn marks and achieving uniform surface quality.

Machine operators in Samshion Rapid closely monitor spark gap voltage and wire feed during the initial entry, ensuring stable discharge conditions before the wire engages the workpiece fully.

How Can we Effectively Clean Sharp Corners?

Corner precision is critical for molds and punch dies. At Samshion, our EDM programmers rely on two reliable approaches:

Graphic-Based Corner Cleaning

Before machining, the drawing is pre-processed in CAD. Operators add small clearance shapes at the corner, ensuring the wire fully cuts the geometry.

Compensation-Based Corner Cleaning

When geometry editing is not possible, we introduce a small inner-radius compensation—typically around 0.09 mm for 0.25 mm wire. During cutting, this controlled overcut removes micro material remnants, effectively achieving a crisp corner.

Samshion’s long-term experience shows that compensation-based cleaning not only sharpens corners but also improves repeatability for multi-cavity molds.

Each corner is verified under a 20x microscope by our quality control department to confirm consistency before polishing or fitting.

How Can Samshion team Prevent Deformation?

Deformation is one of the most common—and frustrating—issues in precision EDM machining. It can originate from residual stress in the material or from unbalanced clamping during machining.

Material Treatment

Before EDM, Samshion’s heat treatment workshop always performs tempering and stress relief to eliminate internal stress, particularly for hardened materials(like SKD11 or DC53).

Process Strategy

Select proper entry and support points. Improper support can cause thin areas to bend after roughing.

Use multiple supports for long or large workpieces. Our operators often add two or more supporting bridges to distribute stress evenly.

When the workpiece tends to deform during threading, we drill start holes and use them as stable entry points for wire cutting.

How Do You Maintain Dimensional Consistency for Thick Workpieces?

Tall or thick parts can exhibit top-bottom deviation due to wire deflection or flushing pressure differences.

At Samshion, we guarantee consistency between top and bottom surfaces through a combination of advanced setup and process tuning:

1.Increasing wire feed speed and tension, improving wire straightness.

2.Repeating the first finishing pass, which primarily defines the geometry.

3.Fine-tuning servo voltage (SV) to correct mid-section bulging or concavity.

4.Using taper compensation in the program (typically 0.002 mm) to ensure parallelism.

Our quality control team verifies each high-thickness workpiece using CMM (Coordinate Measuring Machine) to confirm consistent top and bottom dimensions.

How Can we Achieve Burr-Free (Chip-Free) Machining?

Clean, burr-free edges are a signature of Samshion’s work. We implement two main techniques:

Software-Controlled Burr-Free Mode

Our Mitsubishi MV series and Sodick AQ series EDM machines are equipped with built-in burr-free cutting modes. These functions automatically control discharge energy and flushing direction to minimize micro-recast layers, leaving surfaces clean and ready for direct assembly.

Multi-Cut Offset Control

For parts requiring extreme precision, Samshion’s operators perform multiple finishing passes with progressively reduced offsets.

By fine-tuning discharge energy and feed rate in each pass, the final surface becomes uniform, free of spark pits, and with minimal heat-affected zones.

In high-polish molds or electronic connector dies, this method ensures no post-processing such as polishing or deburring is required.

What Are the Best Methods for Wire-Free (No Wire Tail) Cutting?

At Samshion, when producing micro punches or precision inserts, we’ve found that wire tails left by wire EDM can cause serious fitting issues if not properly managed.

Copper Shim and Adhesive Technique

After the final pass, the operator places copper shims around the workpiece and applies a minimal amount of glue to hold it. This method is effective for medium-sized parts, but requires careful control—too much adhesive can cause short circuits.

Secondary Clamping for Finishing

For larger or batch-produced components, our team uses precision re-clamping to remove support tabs cleanly. For small batch parts, fixture hole machining helps improve alignment and overall efficiency.

How Do You Ensure Precision When Cutting Terminal Dies?

When working on high-precision terminal dies or templates, accuracy and positional consistency are crucial.

Samshion Rapid’s standard process is:

1.Perform rough cutting on all holes first without finishing passes.

2.Surface grind the plate to eliminate minor warping caused by roughing.

3.Execute final finishing cuts to restore geometry and position accuracy. Every terminal die component is inspected under a microscope and measured using 2D projectors and height gauges before final assembly. This multi-layer verification guarantees consistent punch-to-die clearance and perfect alignment in production tools.

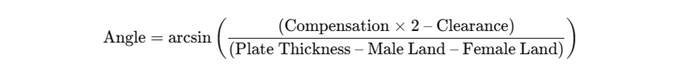

How Should You Calculate Angles for Shared Male/Female Dies or Stripper Plates?

When a male and female die share the same template or when stripper plates are reused, our programmers calculate the cutting angle as follows:

In most cases, Samshion apply a reverse taper cutting strategy for proper fitting.

For shared stripper plates, two design options are common:

Step-type (tiered) structure – preferred for most die applications.

Angle-controlled structure – similar in principle but without a straight body section.

The Samshion Team Behind Every Precision Cut

Behind every precise EDM job at Samshion, there’s a coordinated effort between programmers, machine operators, and quality inspectors.

Programming Department – Engineers use advanced CAM software to simulate tool paths and optimize entry points, and it can reduce unnecessary wire motion.

Operation Team – Skilled operators manage wire tension, discharge settings, and flushing conditions in real-time to maintain consistent accuracy.

QC Department – Equipped with CMMs, projectors, and height gauges, our inspectors verify every dimension before shipment.

We believe precision is achieved not only through machines but through a disciplined workflow and teamwork. Every operator in our EDM department is trained to follow a detailed inspection checklist after each cut, ensuring every component meets international tooling standards.

Conclusion

Wire EDM machining may appear simple, but perfection comes from careful control of every detail—from stress relief and wire entry to corner compensation and taper correction.

At Samshion Rapid, we combine advanced technology, precise process control, and experienced technicians to ensure every EDM part achieves flawless geometry, stable dimensions, and superior surface quality.

Whether it’s for high-precision molds, stamping dies, or custom components, our team’s craftsmanship and commitment to detail guarantee results that meet the world’s most demanding standards.