Computer Numerical Control (CNC) machining has completely reshaped the way modern manufacturing works. For over 70 years, it has been the backbone of precision engineering, making it possible to create reliable, accurate, and functional parts across almost every industry.

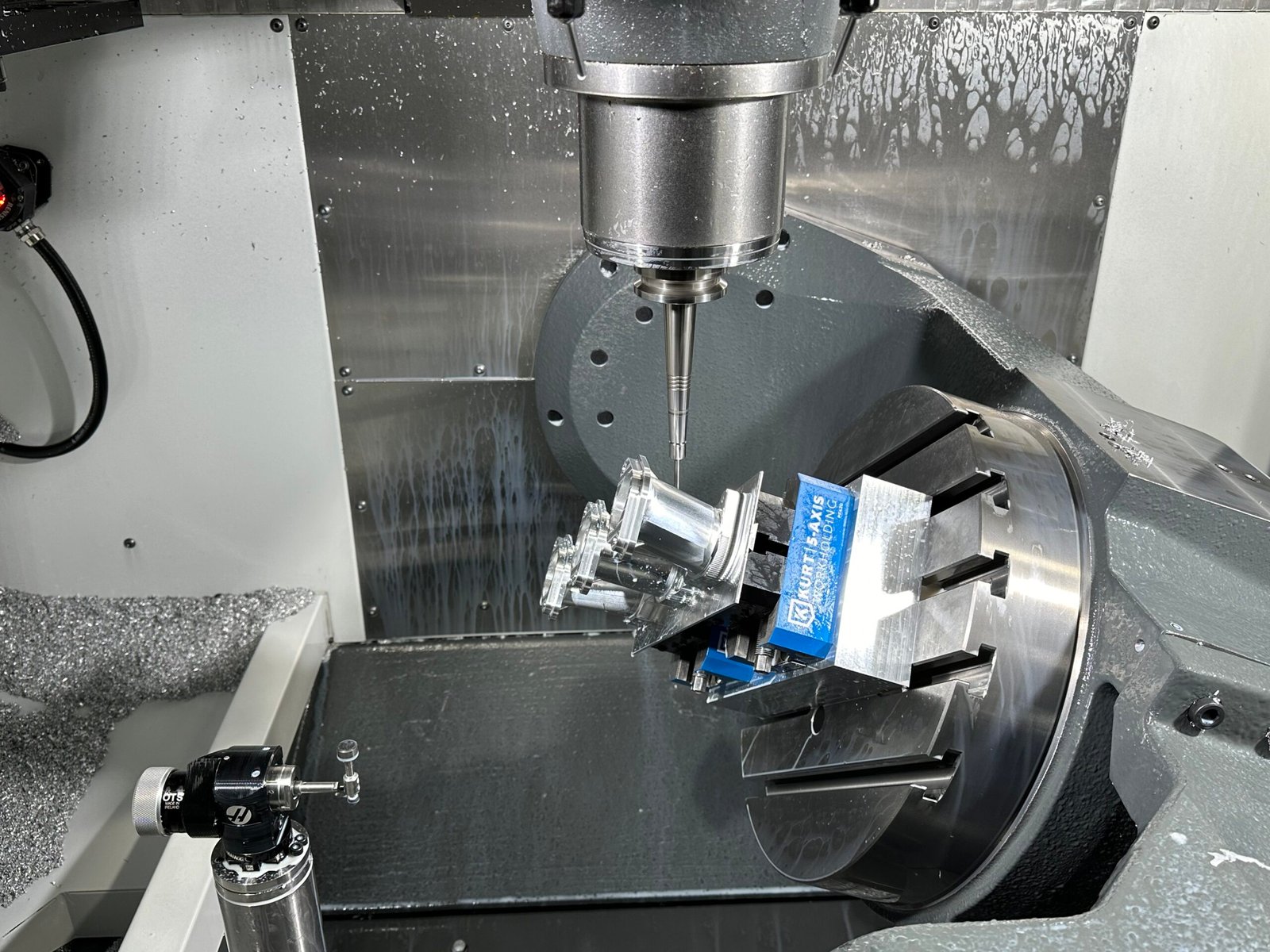

Among its many applications, CNC prototype machining stands out as one of the most valuable. When companies need to test designs, verify functionality, or shorten development cycles, CNC prototyping provides the perfect solution.

In this article, we’ll walk you through what CNC prototype machining is, how it works, the advantages and limitations, and why it’s often the best choice for creating functional prototypes.

What is Prototype Machining?

Prototype machining is the process of producing a small batch of parts that closely resemble the final product. These prototypes serve multiple purposes:

- Test how a digital design looks and performs in the real world

- Evaluate the strength, durability, and functionality of the part

- Detect and correct design flaws before moving into mass production

By catching issues early, CNC prototyping saves significant time and costs in later stages of production.

Why CNC Machining is Ideal for Prototyping

To put it simply: CNC machining is the go-to technology for prototyping. Here’s why:

- Precision & Accuracy – CNC machines achieve extremely tight tolerances, ensuring that prototypes match the exact design specifications.

- Repeatability – Every part made with the same program is an exact replica, guaranteeing consistency.

- Speed – No molds or special tooling are required. Once the CAD/CAM file is ready, prototypes can be produced quickly.

- Cost Efficiency – Fixing design errors at the prototype stage prevents expensive mistakes in mass production.

- Material Flexibility – Unlike 3D printing, CNC machining works with a wide range of materials, including aluminum, steel, titanium, plastics (ABS, PC, POM), and more.

This flexibility makes CNC prototyping suitable for industries where both performance and material properties matter.

Limitations of CNC Prototype Machining

While CNC prototyping is highly versatile, it does have some limitations:

- Material Waste – As a subtractive process, more raw material is consumed compared to additive processes.

- Geometrical Restrictions – Very complex internal geometries may not be possible with CNC.

- Technical Expertise – Skilled operators and engineers are needed to create accurate CAD files and run CNC machines.

- Higher Cost vs. 3D Printing – Although more precise and versatile, CNC prototyping can be more expensive when compared to simple 3D-printed plastic prototypes.

Applications of CNC Prototypes Across Industries

CNC prototype machining plays a key role in R&D and new product development across many industries:

- Automotive – Prototyping gears, housings, and engine parts with tight tolerances

- Aerospace – Testing lightweight yet durable components for aircraft and equipment

- Medical – Producing surgical instruments, prosthetics, and medical device parts that demand microscopic precision

- Architecture & Construction – Creating functional models and custom design elements

- Military & Defense – Developing prototypes for vehicles, weapons, and equipment that require strong, reliable materials

- Oil & Energy – Manufacturing parts that withstand high pressure, heat, and extreme environments

CNC Prototype Machining vs 3D Printing

Both CNC machining and 3D printing are popular prototyping methods. Here’s a quick comparison:

- CNC Machining → Subtractive process, supports metals & plastics, higher precision, faster for larger runs.

- 3D Printing → Additive process, limited to thermoplastics, great for complex geometries but slower for scaling up.

In many cases, CNC machining is chosen when functional testing, material strength, and real-world performance are critical.

Tips for Better CNC Prototyping

To maximize the quality of CNC prototypes, keep these tips in mind:

- Optimize cavity depth, hole sizes, and avoid unnecessary complexity in CAD models

- Maintain minimum wall thickness (≥0.8mm for metals, ≥1.5mm for plastics)

- Choose CAD software that best fits your industry needs

- Keep drawings simple and split overly complex parts into multiple components

Final Thoughts

CNC prototype machining bridges the gap between concept and production. It helps companies innovate faster, reduce risks, and bring products to market with confidence.

At Samshion, we specialize in CNC machining services for prototypes and low-volume production. Whether you need metal or plastic prototypes, we deliver precision parts with fast turnaround and competitive pricing.

Ready to turn your design into a real product? [Contact us today] to get a free CNC prototyping quote!

Frequently Asked Questions

1. Is CNC prototyping the best choice for prototypes?

Yes—when precision, speed, and material flexibility are important, CNC machining is usually the best solution.

2. Which is cheaper: CNC prototypes or injection-molded prototypes?

For small batches, CNC machining is more cost-effective. Injection molding becomes cheaper only at large-scale production.

3. How much does CNC prototyping cost?

The price depends on part complexity, materials, and the number of axes required. On average, CNC machining ranges from $25/hour for basic 3-axis machining up to $80/hour for multi-axis work.