Introduction: Understanding CNC Turning and Milling

When you’re looking for precise, high-quality parts for your project, choosing the right manufacturing method is crucial. CNC turning and CNC milling are two of the most popular machining methods used in the manufacturing industry. While both processes involve computer-controlled machines to shape and form parts, they are quite different in terms of how they operate and the types of parts they produce.

In this blog, we’ll break down the key differences between CNC turning and CNC milling, and help you determine which one is best suited for your needs. Whether you’re designing a part for aerospace, automotive, medical devices, or another industry, understanding these differences will ensure that your parts are made with the right process, precision, and efficiency.

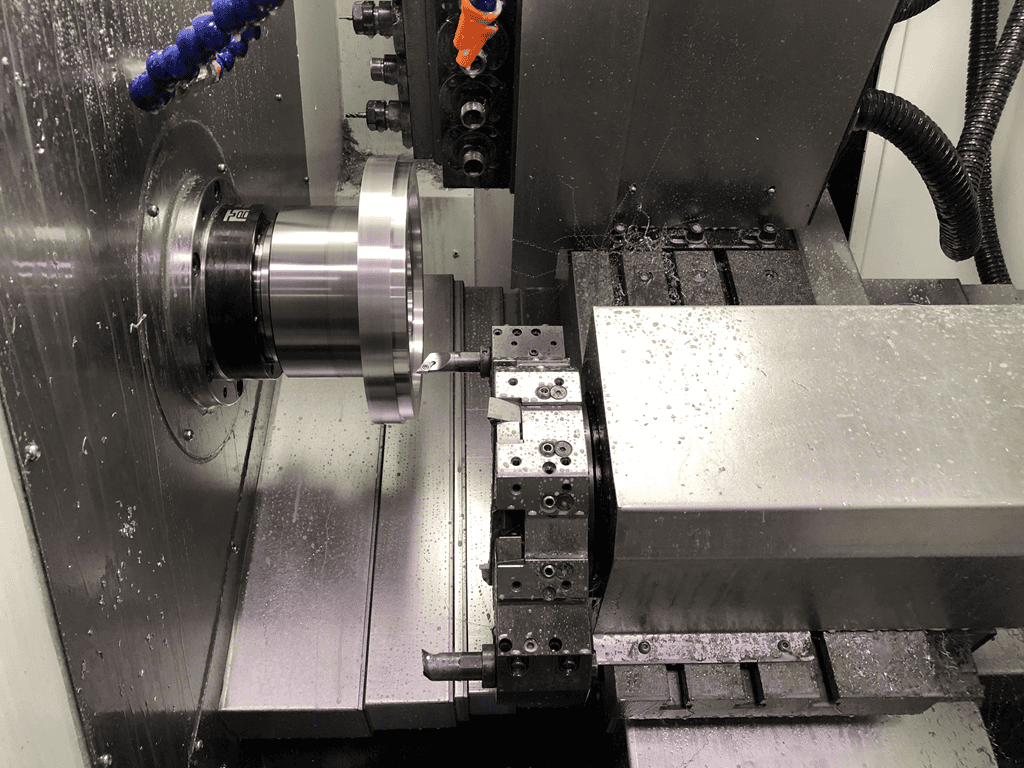

What is CNC Turning?

CNC turning is a machining process where a rotating workpiece is shaped by a stationary cutting tool. The cutting tool removes material from the workpiece, which is typically held in place by a chuck or collet. The rotation of the workpiece allows the cutting tool to create round or cylindrical parts with high precision.

Key Features of CNC Turning:

Rotating Workpiece: The main characteristic of CNC turning is that the workpiece rotates while the cutting tool stays in a fixed position.

Ideal for Symmetrical Parts: CNC turning is commonly used for creating cylindrical, conical, and spherical parts.

High-Speed Machining: CNC turning is often faster than CNC milling, especially for simpler parts.

Common Uses: It’s perfect for parts such as shafts, pins, bolts, bushings, and round bars that require a smooth, uniform shape.

Advantages of CNC Turning:

Faster production for simple geometries

Cost-effective for high-volume, repetitive part production

High precision for round and cylindrical parts

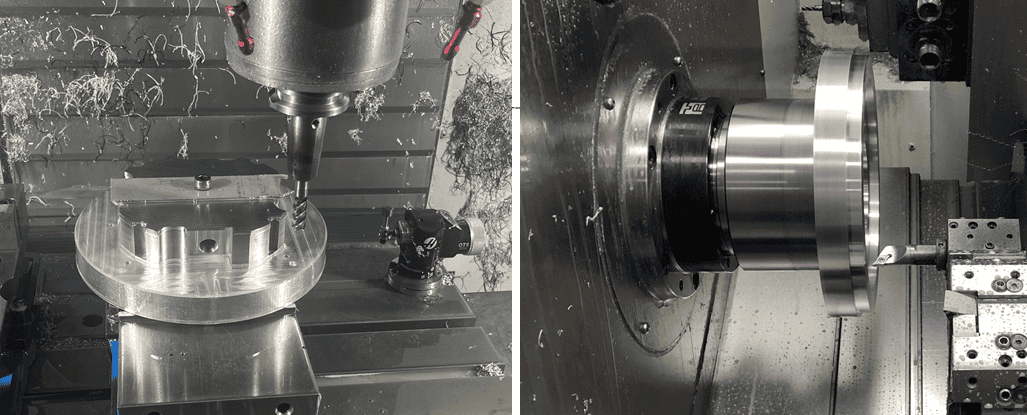

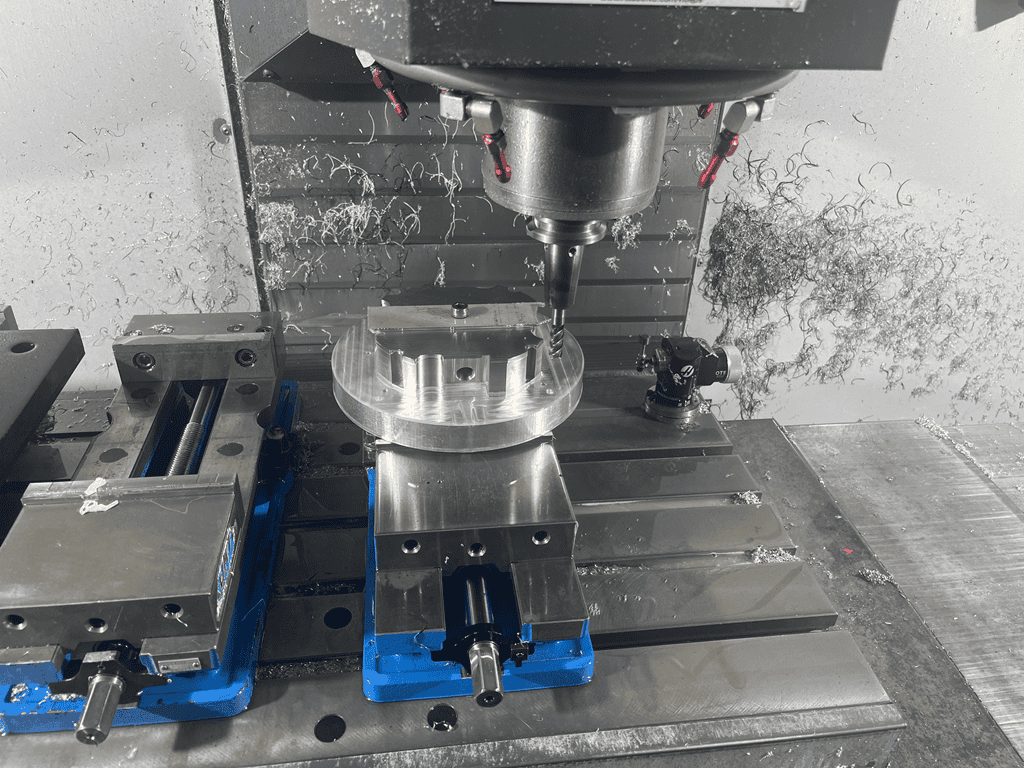

What is CNC Milling?

CNC milling involves a stationary workpiece that is shaped by rotating cutting tools. The cutting tools can move along multiple axes (typically 3, 4, or 5), allowing for the creation of complex, intricate designs that aren’t achievable with turning alone. Unlike CNC turning, which is ideal for round parts, CNC milling is better suited for parts with flat surfaces, holes, and non-circular shapes.

Key Features of CNC Milling:

Stationary Workpiece: The workpiece remains fixed while the cutting tool moves around it, which allows for a wider range of shapes and sizes.

Multiple Axes of Movement: CNC milling machines typically operate on 3 to 5 axes, which makes them ideal for more complex parts with intricate geometries.

Versatile for Complex Parts: CNC milling is used to produce parts with flat surfaces, slots, pockets, and holes.

Common Uses: It is used for producing parts like machine housings, brackets, gears, and components with complex features or non-symmetrical shapes.

Advantages of CNC Milling:

Ability to produce complex shapes and geometries

Suitable for high-precision parts with fine details

Flexible for creating parts with multiple features like holes, slots, and threads

CNC Turning vs Milling: Key Differences

| Feature | CNC Turning | CNC Milling |

|---|---|---|

| Workpiece Movement | Rotates while cutting tool is stationary | Cutting tool rotates while workpiece is stationary |

| Ideal Part Shapes | Best for cylindrical, conical, and round parts | Best for flat, complex, and non-circular shapes |

| Precision | High precision for symmetrical parts | High precision for intricate geometries and non-round parts |

| Production Speed | Faster for simple designs | Slower for more complex designs |

| Common Applications | Automotive, aerospace, medical (e.g., shafts, pins, bushings) | Aerospace, medical, and industrial (e.g., gears, housings, machine parts) |

Which Process Should You Choose for Your Project?

Choose CNC Turning If:

You need cylindrical or symmetrical parts (e.g., shafts, bushings, or bolts).

Your design requires a high-speed machining process for simpler geometries.

You need cost-effective, high-volume production of similar parts.

Choose CNC Milling If:

You need parts with complex shapes, such as those with flat surfaces, holes, pockets, or geometries that can’t be created with turning.

Your project involves intricate features or non-symmetrical components (e.g., gears, housings).

You need high precision for parts that require fine details and multiple features.

Conclusion: CNC Turning vs Milling – What’s Right for You?

Both CNC turning and CNC milling are essential processes in modern manufacturing, but each has its strengths depending on the part geometry and production needs. If your part is simple and symmetrical, CNC turning may be the best choice. If you require intricate designs or non-cylindrical parts, CNC milling is your go-to option. In some cases, a combination of both processes may be required to meet your specific needs.

By understanding the differences between CNC turning and CNC milling, you can make more informed decisions, reduce costs, and streamline your production process.