What is the Strategic Value of Five-Axis Machining?

Five-axis machining represents a major advancement in modern CNC manufacturing, enabling the efficient production of highly complex and precision-critical components. By allowing simultaneous motion along five independent axes—three linear and two rotational—this technology overcomes the geometric and economic limitations of traditional three-axis machining.

Originally developed in the 1940s to meet aerospace manufacturing requirements, five-axis machining has since become a cornerstone technology across industries such as aerospace, automotive, medical devices, energy equipment, mold and die manufacturing, and defense. Its defining characteristic is the ability to machine complex geometries in a single setup while maintaining optimal cutting conditions throughout the process.

At its core, five-axis machining is a subtractive manufacturing process that removes material from a solid workpiece using computer numerical control (CNC), achieving shapes that would otherwise require multiple setups, specialized fixtures, or entirely different manufacturing methods.

What are the Fundamental Principles Behind 5-Axis Technology?

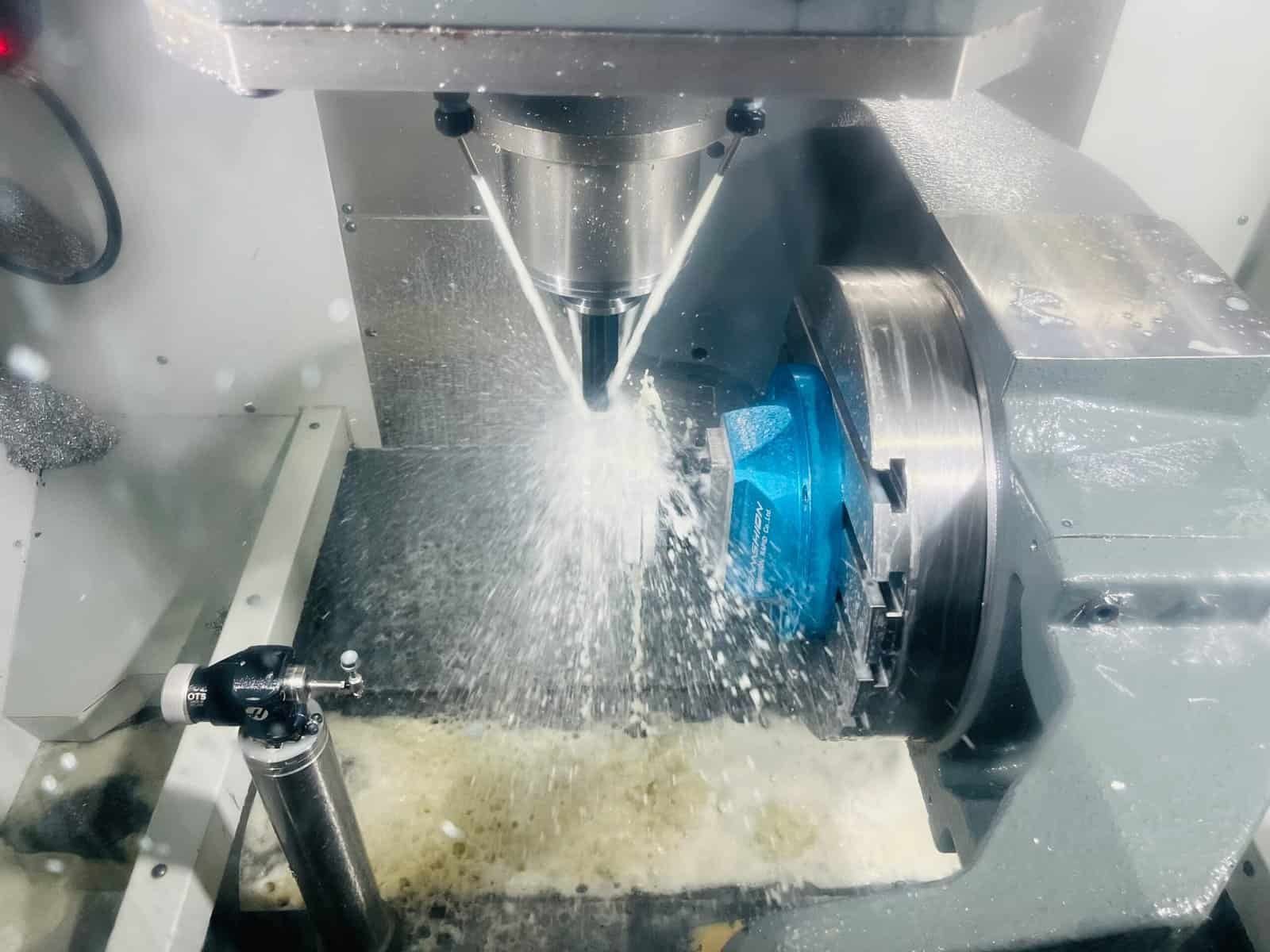

Five-axis machining is the way to make things using subtractive manufacturing technology. It gives us a lot of freedom to make complex shapes. At Samshion Rapid, we use five-axis machines to make things that are really hard to design. We can make things that regular three-axis systems cannot make. Five-axis machining is what we use to tackle the design challenges.

What Is Five-Axis Machining?

The thing, about five-axis machining is that it is a complicated process that uses computers to control the machines. This process is special because the tool that cuts the material or the material itself can move in five directions at the same time. This synchronized movement includes:

Three Linear Axes: X, Y, and Z (providing the standard directional movement).

Two Rotational Axes: Chosen from A, B, or C (depending on the specific machine kinematics, such as a trunnion table or a swiveling head).

It is really good at letting our machines work on every part of something in one go. This means we do not have to move the thing by hand. 5-axis machine helps us get the details right reduces mistakes that people make and gives the parts a better finish on complicated shapes that are not straight.

Core Operating Principle

The idea behind 5-axis machining is that the tool is always moving to the right position. This is called Continuous Tool Orientation Control. When you use a 3-axis machine the tool stays up and down.. With our five-axis machines the tool can move at an angle to the workpiece surface and it changes this angle all the time while it is cutting. This means the tool and the workpiece surface are always in the position, for five-axis machining to work properly.

By keeping this alignment the same all the time the machining process does a very important things really well:

The tool always cuts the material at the angle. This means it uses the part of the cutting edge. The tool is designed to do this all the time. It always finds the spot to cut the material, which is the optimal spot, for cutting also known as the “sweet spot” of the cutting edge. The tool maintains this cutting engagement.

The machine helps to reduce tool deflection and vibration. This is because it can tilt to avoid hitting things, which means we can use tools. When we use tools the whole setup becomes a lot more rigid. This is really important, for the Reduces Tool Deflection and Vibration of the tools. So the Reduces Tool Deflection and Vibration is improved because of this.

The surface finish is really improved when you use this method. You get surfaces that are curved in a nice way. This happens because the tool is always touching the surface. It stops the surface from having a lot of steps, in it which is something that can happen when you are using a 3-axis milling machine to make something.

This thing really helps your tools longer. When you use it the tools do not get worn out fast because they do not vibrate as much. This means that the tools will stay sharp for a time. So when you are making a lot of something all of the things you make will be the same because your tools are still sharp. This is really good, for Extends Tool Life.

Increases Material Removal Efficiency: Faster feeds and speeds can be maintained even on complex geometries, shortening overall cycle times for our clients.

How Do the Five Axes Function in Practice?

5-axis machining systems consist of three linear axes and two rotational axes, each serving specific functions in creating complex geometries. Understanding these axes is crucial for anyone working with five-axis CNC machining systems.

Linear Axes

X-axis: It is the movement of something from left to right within an area where machining can be done. The X-axis shows how things can move horizontally which means from one side, to the other.

Y-axis: Horizontal movement forward and backward, representing longitudinal motion within the work envelope.

Z-axis: Vertical movement up and down, controlling depth of cut and tool engagement.

Rotational Axes

A-axis: Rotation around the X-axis, allowing access to angled surfaces by tilting forward and backward.

B-axis: Rotation around the Y-axis, providing swivel motion for complex geometries.

C-axis: Rotation around the Z-axis, creating spin motion, especially useful for cylindrical parts.

Different machine configurations use combinations such as A+B, B+C, or A+C rotational axes. The choice depends on part geometry, size constraints, and required precision. Head/table configurations combine rotary table movement with spindle head rotation, while table/table systems use two rotary axes on the workpiece side.

What are the Main Types of Five-Axis Operations?

Simultaneous Five-Axis Machining

Simultaneous five-axis machining involves all five axes moving continuously during cutting operations, enabling machining of complex surfaces with constantly changing orientations. This approach is ideal for freeform surfaces such as turbine blades, compressor blades, and complex molds.

During simultaneous operations, the CNC system coordinates all axes to maintain consistent chip load and surface finish. This requires sophisticated CAM software capable of generating smooth, collision-free toolpaths while optimizing cutting conditions. The result is superior surface finishes and the ability to machine geometries impossible with traditional methods.

In simultaneous five-axis machining, all five axes move continuously during cutting. This approach is essential for:

Freeform surfaces

Turbine blades

Complex molds

Aerospace and medical components

Advantages include superior surface finish, consistent chip load, and the ability to machine continuously varying geometries.

3+2 (Indexed) Machining

3+2 positioning, also known as five-axis indexing, involves locking the rotational axes into specific positions before performing three-axis machining operations. This approach simplifies programming and is suitable for angled holes, multi-sided features, and simpler geometries.

Many manufacturers adopt 3+2 machining as an entry point before advancing to full simultaneous five-axis programming.

This method:

Simplifies programming

Reduces collision risk

Is well suited for angled holes and multi-sided features Many manufacturers adopt 3+2 machining as an entry point before progressing to full simultaneous five-axis operations.

Which Machine Configuration is Right for Your Project?

Table/Table Configuration

In table/table configurations, the workpiece is positioned on rotary tables while the spindle head remains stationary. This design offers excellent rigidity and is well suited for heavy or large components, such as aerospace structures and energy equipment housings.

Both rotational axes are applied to the workpiece via rotary tables.

Advantages:

High rigidity

Suitable for heavy or large parts

Stable spindle characteristics

Typical applications: Aerospace structures, energy equipment, large housings

Head/Head Configuration

Head/head machines place both rotational axes in the spindle head, allowing the cutting tool to approach the workpiece from virtually any angle. This configuration excels at machining lightweight, highly complex parts, including medical implants and precision molds.

Advantages:

Maximum tool orientation flexibility

Stationary workpiece

Excellent for complex, lightweight parts

Typical applications: Medical implants, precision molds, aerospace components

Head/Table Configuration

Head/table configurations combine a rotary table with a tilting spindle head, offering a balanced solution suitable for a wide range of part sizes and complexities. Trunnion table systems and swivel head designs are common examples.

Advantages:

Balanced versatility

Suitable for a wide range of part sizes and geometries

Common variants include trunnion tables and swivel head designs.

Why Choose 5-Axis Machining with Samshion Rapid?

Maximizing Efficiency and Speed

The time it takes to set things up is a lot less. We are talking about 60 to 80 percent setups. This is because traditional machining is really slow. You have to flip the parts over and clamp them again times.

Samshion Rapid uses 5-axis centers. This means it can get to every angle without having to stop and start again. So we can do everything in one setup. This makes things a lot faster. We do not have to waste hours doing things by hand.

This really helps when we are making prototypes. We can get them done quicker. Haas system is also a help. It saves us a lot of time with programming prototypes and making the setup time a lot less.

Faster Cycle Times, which means we can get things done twenty five to fifty percent faster is a deal. Time is really important when we are making prototypes quickly. The reason we can do this is because of 5-axis machining. This type of machining lets us plan the path for our tools and remove material faster. When we are working with shapes our engineers can make the whole process up to half as fast. This means that Faster Cycle Times with 5-axis machining can get your project from the computer to the testing stage faster, than before.

Superior Quality and Precision

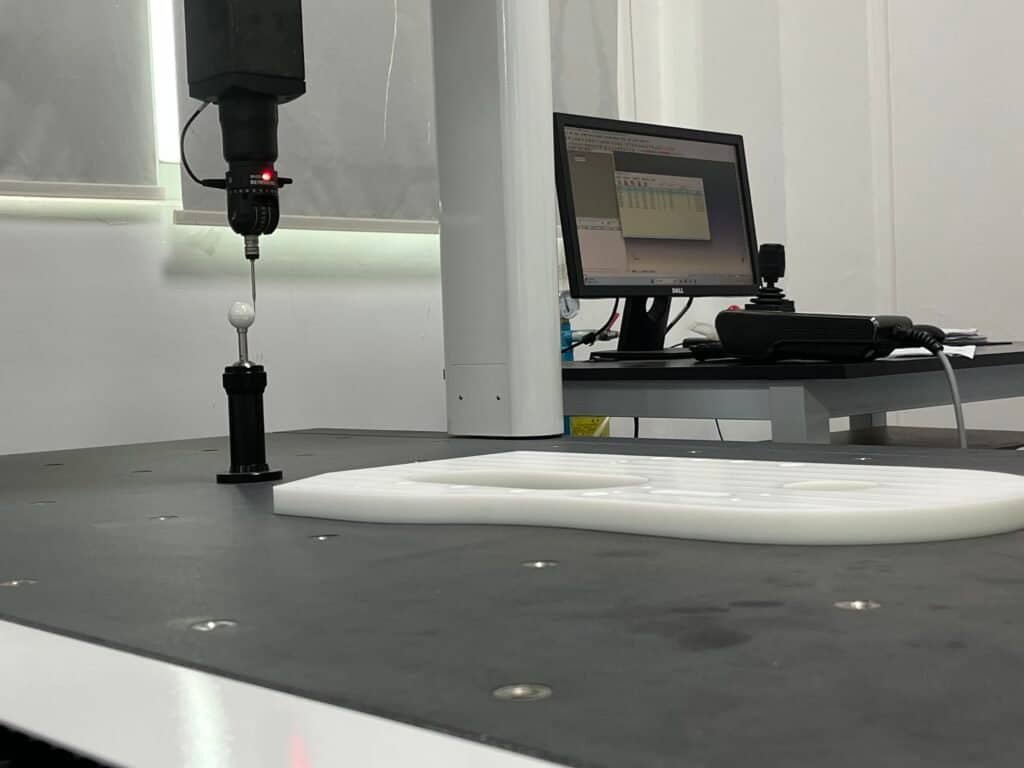

Higher Dimensional Accuracy: When you are working with 3-axis machining every time you have to move the part you are taking a risk. By machining a part within a single coordinate system, Samshion’engineers ensure that every feature is perfectly aligned. This is vital for aerospace and medical components where a deviation of a few microns can be the difference between success and failure.

The Surface Finish is really good because the machine can move in five directions. This means it can tilt and stay at the angle for cutting. That way it can use stronger cutting tools. These tools do not vibrate much. The Surface Finish is very smooth. It is so smooth that you often do not need to polish it by hand or do work on it afterwards. The Surface Finish, from the machine is great.

Advanced Manufacturing Capability

Enhanced Tool Life: Because we make sure they do not hit the tip of the cutter. This is where the cutting speed is zero.

When we do this our tools stay sharp for a time. This means that every part we make is the same. Even the last part we make is as good, as the part. We make sure that our tools are always working well so that our parts are always perfect.

Manufacturing what seems like“Impossible” is now possible.: 5-axis machining allows us to make things that we could not make before like parts, with undercuts, complicated fan blades and complex shapes that look like they are alive. At Samshion Rapid, we help your designers come up with ideas without worrying about the usual limits of manufacturing. This means your designers can think outside the box and create things that’re really different.

The Bottom Line: Strategic Value

These advantages directly translate into lower cost per part, higher throughput, and reduced labor dependency. For our clients, this means getting a more accurate, high-performance part in a fraction of the time, providing you with the ultimate time-to-market advantage.

Where is Five-Axis Machining Most Commonly Applied?

5-axis machining is really good at doing a lot of things which is why it is the best choice, for industries that need to be very precise make complicated shapes and use materials that are very strong. Here are the main areas where five-axis machining is extremely important.

Aerospace

The aerospace industry requires components that are both lightweight and incredibly strong, often involving intricate aerodynamic profiles.

Turbine Blades: Turbine Blades have shapes that are twisted in a special way. The goal of Turbine Blades is to have airflow patterns that’re very efficient. Five-axis machining is necessary to create these shapes in it.

Engine Components: Precision-machined fuel nozzles and combustion chamber parts require multi-axis access to meet strict performance and safety standards.

Structural Brackets: The brackets that make up the airframe are usually made lighter by cutting out parts of them. This is done using a kind of machine that can move in five different directions, which is really good, at reaching into small angled spaces. This helps to make the airframe brackets even lighter. The airframe brackets are a part of the structure and making them lighter helps the whole thing work better.

Flight Control Parts: Critical actuators and gimbal components rely on the high dimensional accuracy of single-setup machining.

Automotive

In the automotive sector, five-axis machining is widely used for high-performance tuning, research and development, and complex tooling.

Transmission Components: Components such as gear housings and valve bodies are indeed critical. If holes and internal structural features can be machined simultaneously, the manufacturing process for these components can be significantly improved. This means we can avoid numerous operations to ensure transmission components achieve a perfect state.

Engine Blocks: They include cylinder heads and intake manifolds, equipped with numerous components. These parts are manufactured using tools capable of moving in five different directions. This facilitates the proper functioning of engine components and enables efficient energy utilization. The goal is to achieve smoother engine operation and fuel savings. Engine components are an indispensable part of this process.

Performance Parts: Custom-made turbochargers, impellers, and suspension uprights for racing applications require the speed and precision of multi-axis milling.

Complex Housings: Protective enclosures for sensors and electronic control units often feature non-standard mounting angles that are best handled by five-axis machining centers.

Medical Devices

Medical manufacturing often involves small, highly complex parts made from difficult-to-machine materials such as titanium or PEEK.

Orthopedic Implants: Hip, knee, and spinal implants feature organic, bone-mimicking contours that require continuous five-axis movement to achieve a smooth surface finish.

Surgical Instruments: Ergonomic handles and intricate mechanical ends of robotic surgical tools are manufactured with extreme precision to ensure life-critical reliability.

Patient-Specific Prosthetics: Custom-fitted prosthetic joints and dental implants are often machined from 3D scan data, requiring the flexibility of five-axis toolpaths.

Mold and Die

Five-axis machining has revolutionized the creation of tooling used to manufacture other products.

Injection Molds: Machining deep cores and cavities with shorter tools improves mold accuracy and enhances the surface quality of the final plastic parts.

Stamping Dies: High-strength steel dies for metal forming are machined with five-axis precision to ensure long-term durability and accurate alignment.

Complex Cooling Channel Tooling: Modern conformal cooling channels follow the contour of the part geometry, a capability only achievable through advanced multi-axis drilling and milling strategies.

Energy, Defense, and Marine

These sectors require heavy-duty components capable of surviving extreme environments, from deep-sea pressure to high-altitude defense applications.

Turbine Components: Wind, hydroelectric, and gas turbine components rely on five-axis machining to create optimized energy conversion surfaces.

Precision Weapon Systems: Guidance components, fins, and structural airframes for defense applications demand the tightest possible tolerances and repeatability.

Marine Propellers and Engine Parts: Large-scale marine propellers feature complex hydrofoil geometries that must be machined with high surface integrity to prevent cavitation and improve fuel efficiency.

What are the Challenges of 5-axis machining ?

High Capital Investment: A high-quality 5-axis machining center typically requires an investment ranging from $500,000 to over $2M. The reason it costs so much is because of the very precise parts it has like the rotary tables and spindles and the controllers that make it move quickly at the same time. The High Capital Investment, for a 5-axis machining center is really high because it needs these special parts to work properly.

Higher Maintenance and Calibration: These machines have a lot of moving parts and complicated systems so you have to take care of them all the time. So we must adjust them regularly. This is very important to make sure they are accurate to a level. And we need to use tools like laser interferometers and ballbar tests to do this. Regular calibration is necessary for these machines to work properly. The Maintenance and Calibration of these machines is non-negotiable.

Advanced Programming Complexity: Programming 5-axis toolpaths is significantly more difficult than 3-axis work. It requires high-end CAM (Computer-Aided Manufacturing) software and programmers who understand complex kinematics, tool vectors, and singular point management.

Increased Collision Risk: With five axes moving simultaneously, the risk of the spindle or tool holder colliding with the workpiece or the machine table increases exponentially. Samshion Rapid mitigates this by using Digital Twin simulation—verifying every second of the toolpath in a virtual environment before a single chip is cut.

Longer Initial Programming Times: Because of the need for advanced simulation and collision checking, the “front-end” time for a 5-axis project is often longer. However, this is usually offset by the massive reduction in physical setup time on the factory floor.

Skilled Labor Shortage: There is a global shortage of operators and programmers capable of running simultaneous 5-axis systems. Successful implementation requires a dedicated team with a deep understanding of 3D geometry and machine limits. At Samshion Rapid, we invest heavily in continuous training to ensure our team stays at the forefront of this technology.

What Software is Required for Success?

Advanced CAM systems (e.g., Mastercam, NX, PowerMill, Fusion 360)

Machine-specific post-processors

Full-process simulation and collision detection

Digital twin and virtual machining tools

Extensive training (6–12 months typical ramp-up)

CAM software plays a central role in managing machine kinematics, optimizing toolpaths, and ensuring safe, efficient operations.

What is the Expected ROI for 5-Axis Projects?

Key ROI drivers include:

Setup reduction

Cycle time improvement

Labor savings

Scrap and rework reduction

Access to higher-margin work

Typical payback periods range from 48 to 84 months, depending on utilization and part complexity. High-mix, low-volume manufacturers often see the fastest returns.

Conclusion: The Strategic Future of Five-Axis Machining

Five-axis machining is no longer a niche capability but a defining technology of advanced manufacturing. Its ability to produce complex, high-precision components in fewer setups positions it as a strategic investment for manufacturers seeking long-term competitiveness.

While the barriers to entry are significant, organizations that successfully integrate five-axis machining gain substantial advantages in quality, efficiency, and market access.

At Samshion Rapid, we bridge the gap between these technical barriers and your project goals. We have already made the necessary investments in state-of-the-art five-axis machining centers, advanced CAM simulation software, and a world-class engineering team.

Our mission is to ensure that you gain the full advantages of five-axis machining—including superior surface finishes, micron-level accuracy, and reduced lead times—without having to manage the underlying complexities yourself. Whether you are developing an aerospace prototype or a high-performance automotive component, Samshion Rapid is your trusted partner in transforming “impossible” designs into high-quality reality.