At Samshion Rapid, our engineers are asked one question daily: “For this part, should I use CNC machining or 3D printing?” The answer is never black and white. It hinges on a complex equation balancing end-use, material properties, cost, and timeline. This guide cuts through the hype to give you the practical insights you need to make the smartest choice.

When it comes to rapid prototyping and custom part manufacturing, two technologies stand out: 3D Printing and CNC Machining. Both are powerful, both can accelerate product development, but they work in very different ways.

So, how do you decide which one is right for your project? Let’s break it down.

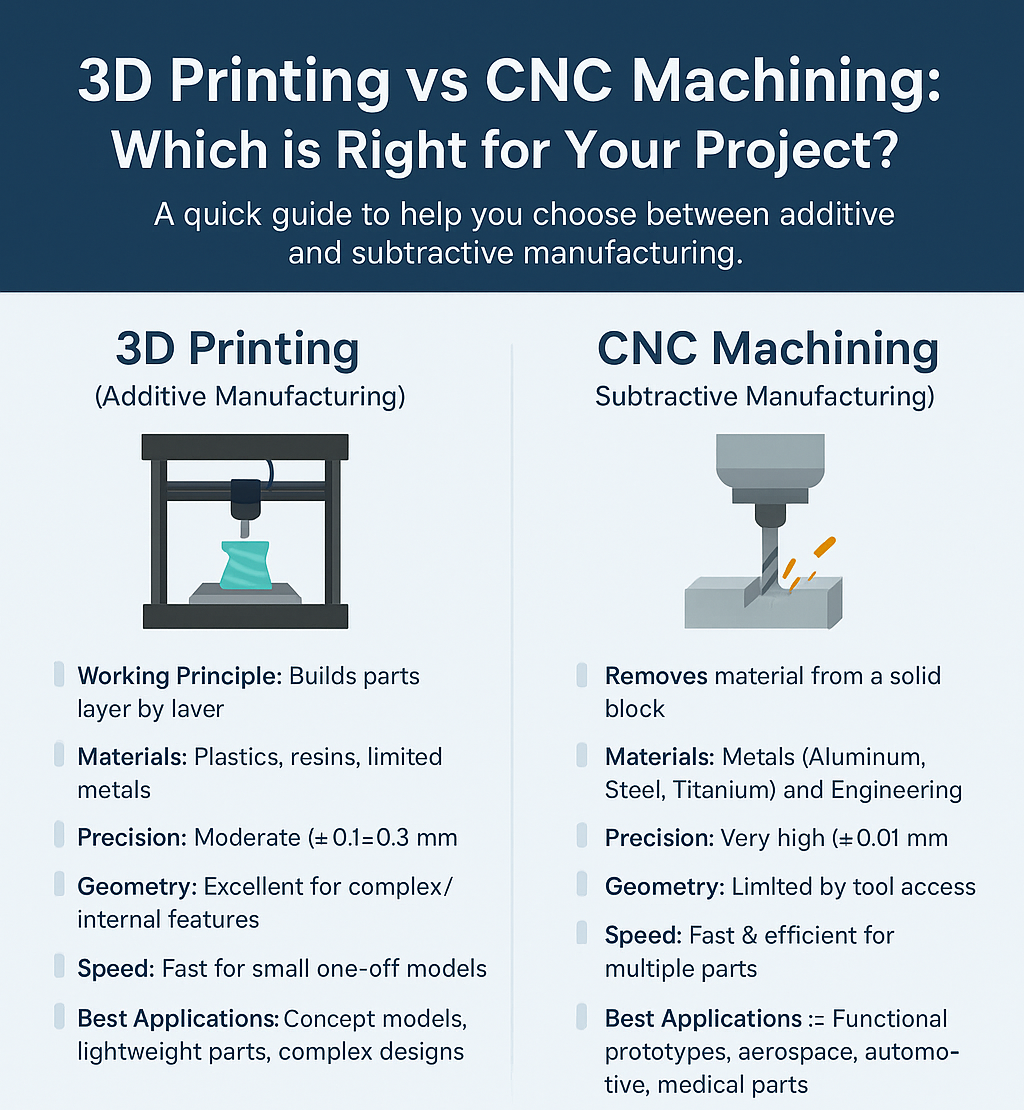

1. Working Principles: Additive vs. Subtractive

3D Printing (Additive Manufacturing)

Builds parts layer by layer from raw material (usually thermoplastics, resin, or metal powders). Ideal for complex geometries and low-volume prototypes.

CNC Machining (Subtractive Manufacturing)

Starts with a solid block of material and removes excess material using cutting tools. Perfect for achieving tight tolerances, high strength, and functional prototypes.

The key difference? 3D printing adds material; CNC machining removes it.

2. Precision and Tolerances

CNC Machining: Offers excellent accuracy (±0.005 in / ±0.01 mm) and repeatability. Suitable for high-performance components where fit and function are critical.

3D Printing: Typically less precise, with tolerances depending on the process (FDM, SLA, SLS, DMLS). Good enough for visual models or low-stress parts, but may require post-processing for tighter accuracy.

If you need high precision and mechanical stability, CNC is the clear winner.

3. Materials and Mechanical Properties

CNC Machining: Works with metals (aluminum, steel, titanium, brass, copper) and engineering plastics (ABS, POM, PC, Nylon). Final parts have real-world mechanical properties.

3D Printing: Strong in plastics (PLA, ABS, Nylon, resin) and now supports some metals (via SLM/DMLS), but strength is usually lower than CNC-milled parts.

For functional testing with production-grade materials, CNC machining is superior.

For concept models or lightweight designs, 3D printing works well.

4. Geometrical Complexity

3D Printing: Excels at complex geometries, internal channels, lattice structures, and organic shapes that CNC cannot easily produce.

CNC Machining: Limited by tool access and cutting angles. Complex internal cavities may be impossible without assembly.

If your part requires complex internal features, go with 3D printing.

5. Speed and Lead Time

3D Printing: Often marketed as “rapid prototyping.” A small part can be printed in hours, but large parts may take much longer.

CNC Machining: Once the CAD/CAM setup is ready, parts can be produced in minutes. Especially efficient for low-volume production.

If you need one-off prototypes quickly, 3D printing may be faster.

If you need several functional parts with precision, CNC machining is faster overall.

6. Cost Considerations

3D Printing: Lower setup costs, no tooling required. Best for small runs or one-off models. However, material costs (resin, powders) can be high.

CNC Machining: Higher upfront setup cost, more waste material. But for multiple parts or when precision matters, CNC can be more cost-effective.

For low-budget concept models, 3D printing wins.

For functional prototypes and repeatability, CNC machining offers better long-term value.

Comparison Table: 3D Printing vs CNC Machining

| Factor | 3D Printing (Additive) | CNC Machining (Subtractive) |

|---|---|---|

| Working Principle | Builds parts layer by layer | Cuts material from a solid block |

| Precision & Tolerance | Moderate (±0.1–0.3 mm, process-dependent) | High precision (±0.01 mm) |

| Materials | Mainly plastics, resins, some metals (DMLS/SLM) | Metals (Aluminum, Steel, Titanium, Brass) + Engineering Plastics |

| Mechanical Strength | Weaker, layer bonding reduces strength | Stronger, material retains original properties |

| Geometrical Complexity | Excellent for complex/internal features | Limited by tool access & cutting angles |

| Surface Finish | Often rough, needs post-processing | Smooth finish, can achieve mirror-like quality |

| Speed | Fast for small one-off parts, slower for larger pieces | Very fast once set up, efficient for multiple parts |

| Cost | Low upfront cost, but higher material price | Higher setup cost, but cost-effective for small/medium runs |

| Waste Material | Minimal material waste | More waste, but recyclable |

| Best Applications | Concept models, architectural designs, custom consumer products | Functional prototypes, aerospace, automotive, medical, defense parts |

7. Industry Applications

3D Printing: Architecture models, medical implants (biocompatible resins), lightweight aerospace structures, custom consumer products.

CNC Machining: Automotive gears, aerospace turbine components, medical instruments, defense hardware, energy sector components.

In many cases, companies use both: 3D printing for concept validation, CNC machining for functional testing.

8. How to Choose: A Practical Decision Framework

Stop thinking about which technology is “better.” Start by asking these questions about your project:

1. What is the part’s primary use?

- Choose CNC for: Functional prototypes that must endure real-world testing and end-use parts that require high reliability, strength, and precise tolerances.

- Choose 3D Printing for: Concept models, fit-and-assembly checks, and parts with geometries impossible to make any other way.

2. What are your volume requirements?

- Choose CNC for: High-volume production (typically > 50-100 parts, depending on complexity). The low per-part cost outweighs the higher setup cost.

- Choose 3D Printing for: Low-volume runs (1-10 parts), custom one-off parts (e.g., medical implants, jigs & fixtures), or bridging production before tooling is ready.

3. How complex is your design?

- Choose CNC for: Parts with relatively simple, blocky, or prismatic geometries.

- Choose 3D Printing for: Parts with complex organic shapes, topologically optimized structures, or internal features that would require multiple CNC setups or assembly.

To visualize this decision process, follow this flowchart:

4. Beyond the Binary: The Hybrid Manufacturing Advantage

The smartest engineers don’t limit themselves. At Samshion Rapid, we often employ a hybrid manufacturing approach:

- 3D Print + CNC Finish: A complex, lightweight base structure is 3D printed, and then CNC machining is used to create precision-machined threads, bores, or mating surfaces. This combines complexity with precision.

- CNC + 3D Printed Jigs: We rapidly 3D print custom jigs, fixtures, and tooling for our CNC production lines, drastically reducing the cost and lead time of manufacturing aids.

5. Conclusion: It’s About the Right Tool for the Job

There is no universal winner.

- CNC Machining is the king of strength, precision, and high-volume economics.

- 3D Printing is the champion of complexity, speed-to-first-part, and design freedom.

9. How to Decide? A Quick Guide

Ask yourself these questions:

Do I need tight tolerances and strength? → CNC Machining

Do I need complex geometry and fast concept models? → 3D Printing

Am I working with metals or engineering-grade plastics? → CNC Machining

Is this just for visual presentation? → 3D Printing

Final Thoughts

Both 3D Printing and CNC Machining are indispensable in modern manufacturing. Choosing the right one depends on your project goals, budget, materials, and required functionality.

At Samshion, we provide CNC machining services and rapid prototyping solutions to help you bring your designs to life—whether you need concept models or functional prototypes ready for real-world testing.

The most effective path is to consult with our manufacturing experts early. Send us your CAD file, and we’ll provide a data-driven recommendation on the most efficient and cost-effective process for your specific project.

Still unsure which process is right for your application? Upload your 3D model today for a free, professional design analysis and quote delivered in 24 hours!