304 stainless steel is one of the most widely used materials in CNC machining due to its excellent corrosion resistance, mechanical strength, and machining versatility. As the workhorse material of stainless steel CNC machining, 304 stainless steel is commonly applied in precision components across medical, aerospace, automotive, and industrial equipment industries. At Samshion Rapid, we specialize in CNC machining 304 stainless steel, achieving tight tolerances of plus or minus 0.005 millimeters through optimized cutting parameters, advanced tooling, and data-driven process control. This technical guide focuses on

In this article, we will explore 304 stainless steel machining parameters, tooling selection, and best practices for achieving high precision and production efficiency.

What Defines 304 Stainless Steel and Its Low-Carbon Variants?

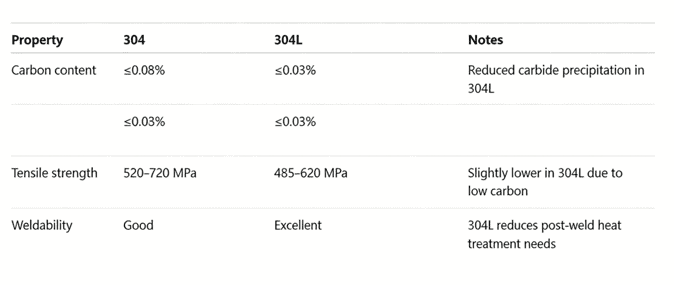

304 stainless steel is a chromium-nickel austenitic alloy from the 18-8 series. Its low-carbon counterpart, 304L, contains a maximum carbon content of 0.03 percent and is specifically engineered to reduce chromium carbide precipitation during welding.

Key Differences Between 304 and 304L

And mechanical property differences between 304 and 304L are minimal, but 304L may have slightly lower yield and tensile strength due to its lower carbon content (Tensile Strength: 485–620 MPa vs 520–720 MPa for standard 304). However, the trade-off is offset by improved weldability and long-term service performance in corrosive environments.

For projects involving welded assemblies, such as medical enclosures or chemical fluid manifolds, Samshion Rapid recommends 304L. Using 304L eliminates the risk of intergranular corrosion and often removes the need for post-weld annealing, significantly reducing total lead times.

What Are the Core Machinability Challenges of 304 Stainless Steel?

304 stainless steel has moderate machinability, rated 45% on the AISI scale compared to 78% for 303 and 40% for 316 stainless steel. Its austenitic structure causes rapid work hardening and localized heat buildup, reducing tool life by 30–40% compared to mild steel.

Factors Affecting Machinability

Work Hardening – 304 stainless steel exhibits a high strain-hardening coefficient (approx. 0.45), meaning the material’s yield strength increases significantly during plastic deformation.

During the initial cutting pass, the material directly beneath the cutting tool experiences severe plastic deformation and becomes harder than the base material. If the subsequent pass uses an insufficient depth of cut, the tool does not properly shear fresh material. This rubbing makes the cutting process much harder creates a lot of heat. This abrasive friction generates intense localized thermal energy, accelerating flank wear and compromising tool longevity.

Heat Generation and Thermal Conductivity – When you are working with carbon steels the heat that is made when you are cutting them is taken away by the chip that is removed.. With materials that are really hard to cut the heat does not go away easily because these materials do not let heat pass through them very well.

Because heat cannot escape quickly through either the chip or the workpiece, it accumulates at the tool–chip interface. This localized heat concentration creates what is often referred to as a “heat sink” effect, where thermal energy is trapped directly at the cutting edge.

Tool Wear – Flank wear rates increase significantly; primary mechanisms are adhesive wear (BUE), abrasive wear, and notching.

When it is being CNC machined, the material will getting hotter, so that it can stick to the cutting edge. This makes a built-up edge on the cutting edge. The stuck pieces break off sometimes. They often take some of the tool coating or the tool itself, with them. This means the surface of the material does not look good and the cutting edge gets damaged fast. The cutting edge and the material you are working with are affected by this process. The material you are working with can stick to the cutting edge. Cause problems.

Surface Finish – Standard turning produces Ra 1.6–3.2 µm; optimized PVD-coated carbide inserts and high-pressure coolant can achieve Ra 0.8 µm.

It sounds like we are dealing with the classic “double-edged sword” of 304 stainless steel. Its fully austenitic microstructure delivers outstanding corrosion resistance, ductility, and toughness, yet that same structure makes it one of the more challenging materials to machine efficiently.

What Should You Consider When Machining 304 Stainless Steel?

Strategic Process Selection

The secret to machining 304 is never letting the tool dwell or rub against the surface, as this triggers immediate work hardening.

Roughing (The Power Phase): Focus on high-speed cutting with aggressive feed rates. The goal is to remove bulk material quickly, ensuring the heat stays in the chip and is carried away before it can soak into the workpiece.

Finishing (The Precision Phase): Use light cuts but maintain a stable feed. Reducing the feed too much will cause the tool to rub rather than cut, ruining the surface finish.

Grade Substitution: If the design allows for slightly lower corrosion resistance (for example, internal mechanical parts), Samshion Rapid may recommend AISI 303. This sulfur-modified grade improves cutting efficiency by 20 to 30 percent, significantly reducing lead times.

Tooling and Coolant

High-performance hardware is required to maintain the tight tolerances of plus or minus 0.005 mm that Samshion Rapid is known for.

Chip Breaker Geometry: Because 304 stainless steel creates long, stringy chips that can mar the surface or wrap around the spindle, carbide tools with aggressive chip breakers are used to break the material into manageable segments.

High-Pressure Systems (70 bar or higher): Standard flood coolant is often insufficient for 304. At high pressure, the coolant acts as a hydraulic wedge, forcing its way into the tool-chip interface to lubricate the most adhesive part of the cut.Synthetic Lubrication: For high-speed milling, Samshion utilizes full synthetic coolants. These provide superior cooling properties compared to traditional emulsions, helping achieve a surface roughness of Ra 0.8 to 1.6 micrometers without secondary polishing.

Productivity and Cost Optimization

In the prototyping and low-volume world, efficiency is measured by time to market.

Tool Life Management: Tooling accounts for 10 to 15 percent of total costs. By optimizing speeds (turning: 160 to 180 meters per minute; milling: 90 to 110 meters per minute), Samshion increases productivity by up to 18 percent while preventing unexpected tool failures that cause downtime.

Digital Monitoring: Implementing online wear tracking allows technicians to change tools just before failure. This prevents scrapped parts, a critical factor when working with expensive stainless steel alloys.

In summary, Samshion Rapid optimizes 304 Stainless Steel production by balancing aggressive roughing cycles with high-stability finishing and advanced PVD-coated carbide tooling. By utilizing high-pressure coolant systems of 70 bar or higher and high-performance synthetic lubricants, they effectively mitigate the 304 grade’s tendency for heat accumulation and work hardening. This data-driven approach, incorporating optimal cutting speeds and real-time tool monitoring, allows us to boost productivity by up to 18 percent while delivering precision components with superior surface finishes and guaranteed structural integrity.

How Can You Optimize Cutting Parameters and Tooling for 304 Stainless Steel?

To achieve the precision and efficiency Samshion Rapid is known for, we follow data-driven machining protocols that balance material removal rates with maximum tool life. Successful machining of 304 stainless steel depends on preventing the material from “fighting back” through excessive heat buildup and work hardening.

Recommended Cutting Parameters: Preventing the Rubbing Effect

Precision 304 machining requires a high-engagement cutting strategy to mitigate the material’s inherent strain-hardening tendencies. By ensuring the cutting edge remains consistently below the work-hardened ‘skin’ of the previous pass, we maintain dimensional stability and prevent premature tool failure

Turning (CNC Lathe):

Cutting speed: The cutting speed is from 160 to 180 meters per minute. This range allows heat to be carried away by the chip before it transfers into the workpiece.

Feed rate: 0.15 to 0.35 millimeters per revolution. A consistent, sufficiently aggressive feed prevents tool dwell, which is the primary cause of surface hardening.

Depth of cut: 1.5 to 3.0 millimeters for roughing, keeping the tool well below any work-hardened surface layer.

Milling (CNC Milling):

Cutting speed: 90 to 110 meters per minute.

Radial engagement: 10 to 30 percent. Lower radial engagement, such as trochoidal milling, reduces tool contact time with hot material and allows cooling between tool rotations.

Specialized Tooling: Precision Through Geometry

Standard cutting tools tend to fail rapidly when machining 304 stainless steel. At Samshion Rapid, we rely on advanced tooling geometry to maintain tight tolerance requirements.

High-Performance Coatings:

Samshion’s team use PVD-coated carbide tools such as TiAlN or AlCrN. PVD coatings are thinner and sharper than CVD coatings, allowing the tool to slice through 304 stainless steel instead of plowing. These coatings also act as a thermal barrier, protecting the tool core from excessive heat.

Sharp Geometry and Positive Rake:

Cutting tools are ground with a positive rake angle of approximately 10 to 15 degrees. This geometry reduces cutting forces and minimizes plastic deformation, which directly lowers the risk of work hardening.

Vibration and Chip Control:

Variable pitch and high-helix end mills are used to suppress harmonic vibration and chatter, which can cause instant tool chipping in austenitic stainless steels. Aggressive chip breaker geometries help break long, stringy chips into manageable segments, preventing chip entanglement and surface damage.

By combining optimized cutting parameters, specialized PVD-coated carbide tooling, and high-pressure coolant systems of 70 bar or higher, Samshion Rapid consistently achieves superior surface finishes of Ra 0.8 micrometers or better. This integrated machining strategy also extends tool life by up to 40 percent, ensuring stable, cost-effective, and high-precision CNC machining of 304 stainless steel.

What Surface Treatments and Protections are Available for 304 Stainless Steel?

The long-term performance of 304 stainless steel components depends heavily on surface condition after machining. Samshion Rapid offers several critical post-processing options.

Passivation removes free iron contamination introduced during machining and restores the stainless steel’s protective chromium oxide layer.

Electropolishing produces a smooth, near-mirror surface finish in the range of Ra 0.4 to 0.8 micrometers and significantly improves corrosion resistance for medical and food-grade applications.

PVD functional coatings can be applied to increase surface hardness and wear resistance for components exposed to abrasive conditions.

These surface treatments and protection strategies ensure long-term stability, aesthetic quality, and reduced maintenance costs for 304 stainless steel components, making them suitable for high-cleanliness, high-corrosion-resistance, and high-decorative-value applications.

Why Is 304 Stainless Steel the “Workhorse” of Global Industry?

In the world of precision manufacturing, 304 Stainless Steel is unparalleled in its versatility. Its “workhorse” status is primarily due to its balanced chemical composition—18% Chromium and 8% Nickel—which allows it to transition seamlessly from a raw block of metal to a high-performance component across nearly every major sector. For CNC machining specifically, its applications are vast because it provides the perfect middle ground between cost-efficiency and extreme durability.

Key CNC Applications by Industry:

Medical & Healthcare: Because 304 can withstand aggressive sterilization chemicals without corroding, it is the standard for CNC-machined surgical instruments, orthopedic implants, and diagnostic equipment housings.

Aerospace & Defense: Its high strength-to-weight ratio and resistance to oxidation at elevated temperatures make it ideal for actuator components, fuel manifolds, and specialized fasteners that must not fail under pressure.

Food & Chemical Processing: Due to its non-reactive nature, it is used to machine complex valve bodies, mixing impellers, and sensor probes that come into direct contact with corrosive fluids or consumable products.

Automotive Engineering: We frequently utilize 304 for high-pressure fuel rails, exhaust manifolds, and decorative trim where both structural integrity and long-term aesthetic appeal are required. At Samshion Rapid, we leverage the inherent toughness of 304 to deliver parts that maintain their structural integrity even after intensive subtractive processing. Whether it’s a high-polish mirror finish for an architectural piece or a tight-tolerance internal component for a laboratory centrifuge, 304 remains the most reliable choice for a “zero-failure” design philosophy.

FAQ: Expert Tips for 304 Stainless Steel Machining

Q1: Why is my tool wearing out instantly?

A1: Samshion’s suggestion is to check your feed rate. If it is too low, the tool may be rubbing against a work-hardened layer. Increasing the feed helps the tool stay ahead of the hardening effect and prolongs tool life.

Q2: Can 304 stainless steel achieve a mirror finish?

A2: Yes. By using sharp PVD-coated carbide tooling and applying electropolishing as a post-process, finishes as smooth as Ra 0.4 micrometers can be achieved.

Q3: What is the best alternative to 304 stainless steel?

A3: If weldability is not required and the component is non-critical, 303 stainless steel offers approximately 20 percent better machinability.

Conclusion

304 stainless steel stands as the premier “workhorse” of modern industry, offering an elite balance of corrosion resistance, structural durability, and versatile formability. Successful production of 304 stainless steel is a balance of science and stability. By optimizing cutting speeds (160–180 meters per minute for turning) and implementing real-time tool wear monitoring, Samshion Rapid boosts production efficiency by 12 to 18 percent while significantly reducing per-part costs. Whether for a single complex prototype or a low-volume production run, our optimized workflow ensures that the inherent strengths of 304 stainless steel are fully realized in the final product.

Do you have a project requiring the durability of 304 stainless steel? Contact Samshion Rapid now for a comprehensive design-for-manufacturing evaluation and see how our optimized machining strategies can bring your design to life with world-class precision.