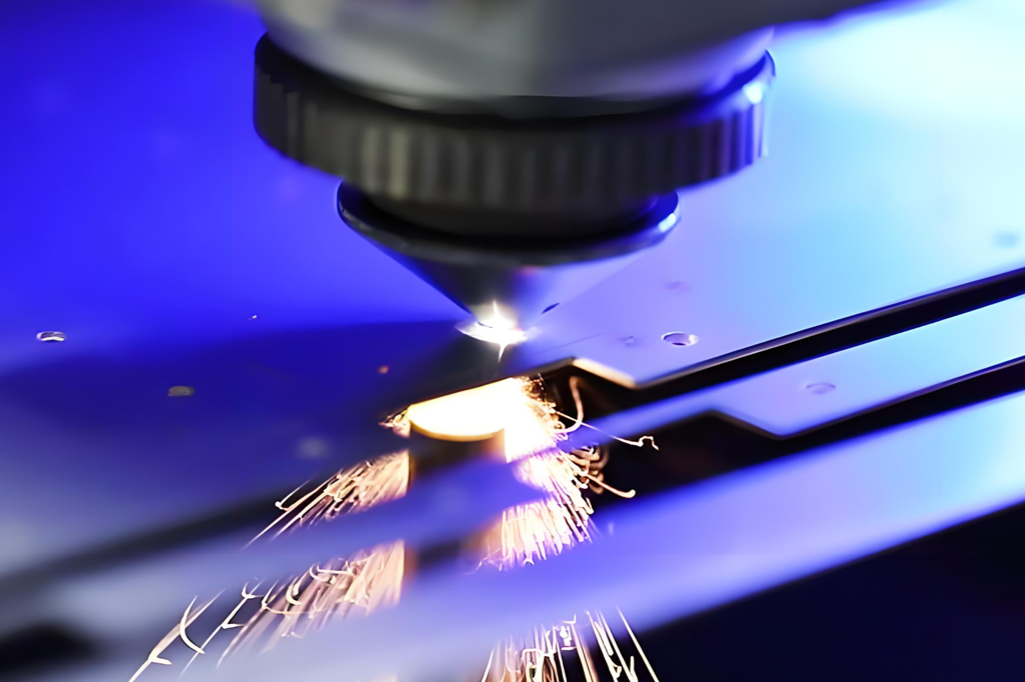

Is Laser Engraving Worth It for Your Business in 2025? | ROI & Insights

In this post, we’ll break down the costs, benefits, and potential of laser engravers, and how to use lasers to create personalized engravings for custom business.At Samshion, our team has extensive experience in rapid prototyping and precision machining. We provide professional manufacturing services to meet the products requirement of hobbyists and businesses. If you’ve ever […]

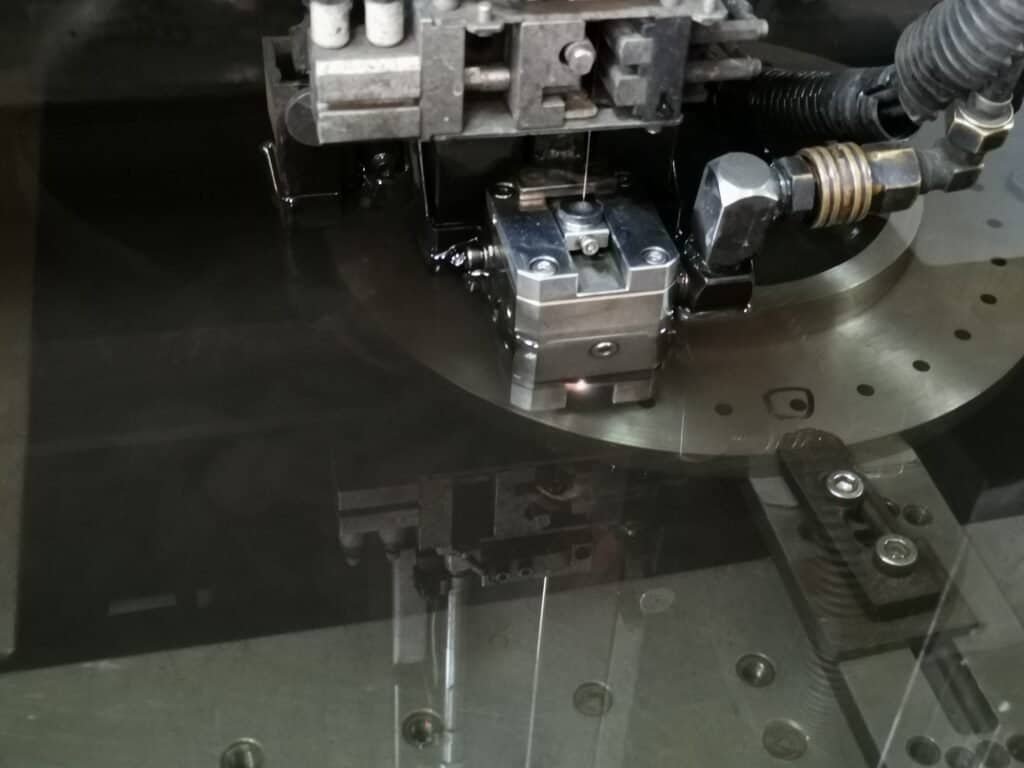

How to Solve Common Problems in Wire EDM Machining: Tool Marks, Corner Cleaning, and Deformation

At Samshion Rapid, precision isn’t just a promise—it’s part of our daily workflow. Our EDM machining team, composed of engineers and operators with over 20 years of hands-on experience, consistently pushes the limits of accuracy and efficiency in fine toolmaking and mold manufacturing. In the field of wire EDM (Electrical Discharge Machining), we often face […]

Do You Really Understand Cutting Tools? A Comprehensive Guide

A good horse needs a good saddle. Using advanced CNC machines is useless if the wrong cutting tools are used! Choosing the right cutting tool material greatly affects tool life, efficiency, quality, and cost. At Samshion, we combine years of prototyping and CNC machining expertise to help clients choose the right tools and materials. What […]

3D Printing: Transforming Manufacturing with Innovation and Precision

Introduction: Why Is 3D Printing Changing the Manufacturing Landscape? In today’s fast-changing manufacturing world, speed, flexibility, and innovation matter more than ever. Traditional methods like CNC machining, stamping, and casting remain important, but companies also need new tools that can shorten development time, reduce costs, and allow more creativity. One of the most powerful tools […]

How to Choose a CNC Manufacturing Supplier: The Ultimate Guide

The constantly changing market needs have necessitated faster and more accurate fabrication of products. CNC machine shops are a product of this industrial revolution. A CNC machine shop continuously advances and invests in technologies to achieve the highest efficiency in manufacturing products. They provide CNC machining services to various businesses for different applications. This guide […]

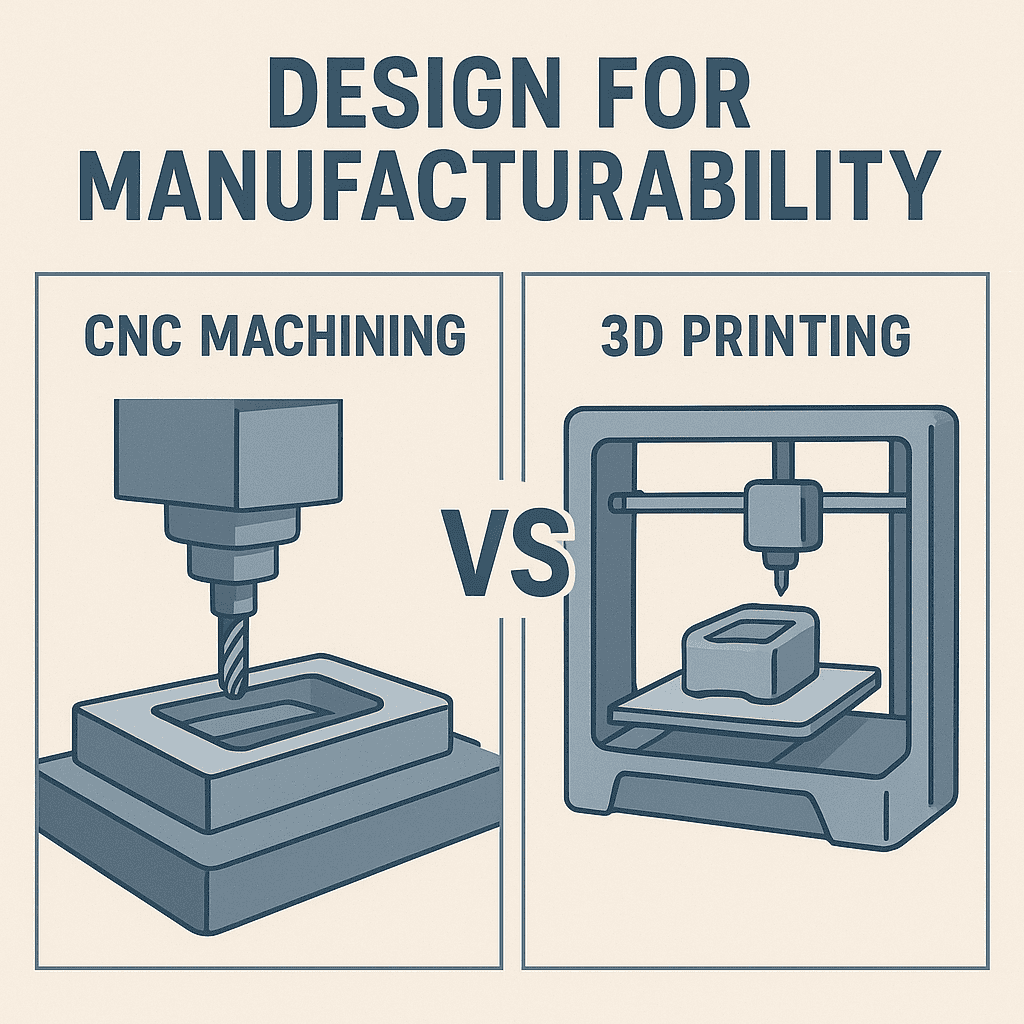

Design for Manufacturability (DFM) Guide: Optimize for CNC Machining And 3D Printing

Introduction: The $5,000 Mistake We Caught in 5 Minutes At Samshion Rapid, a client once sent us a complex aluminum housing design. It looked perfect on screen. But our engineers spotted it immediately: a beautiful, completely un-machinable internal corner. Fixing it before production took a 5-minute design tweak. If we had machined it as-is, it would have […]

Understanding Surface Finish Options for CNC Machined Parts

When it comes to CNC machining services, precision is only half of the story. The other half lies in the surface finish—how the part looks, feels, and performs in real-world conditions. Surface finishes not only improve the visual appeal of CNC machined parts but also enhance durability, corrosion resistance, and functionality. If you’re developing a […]

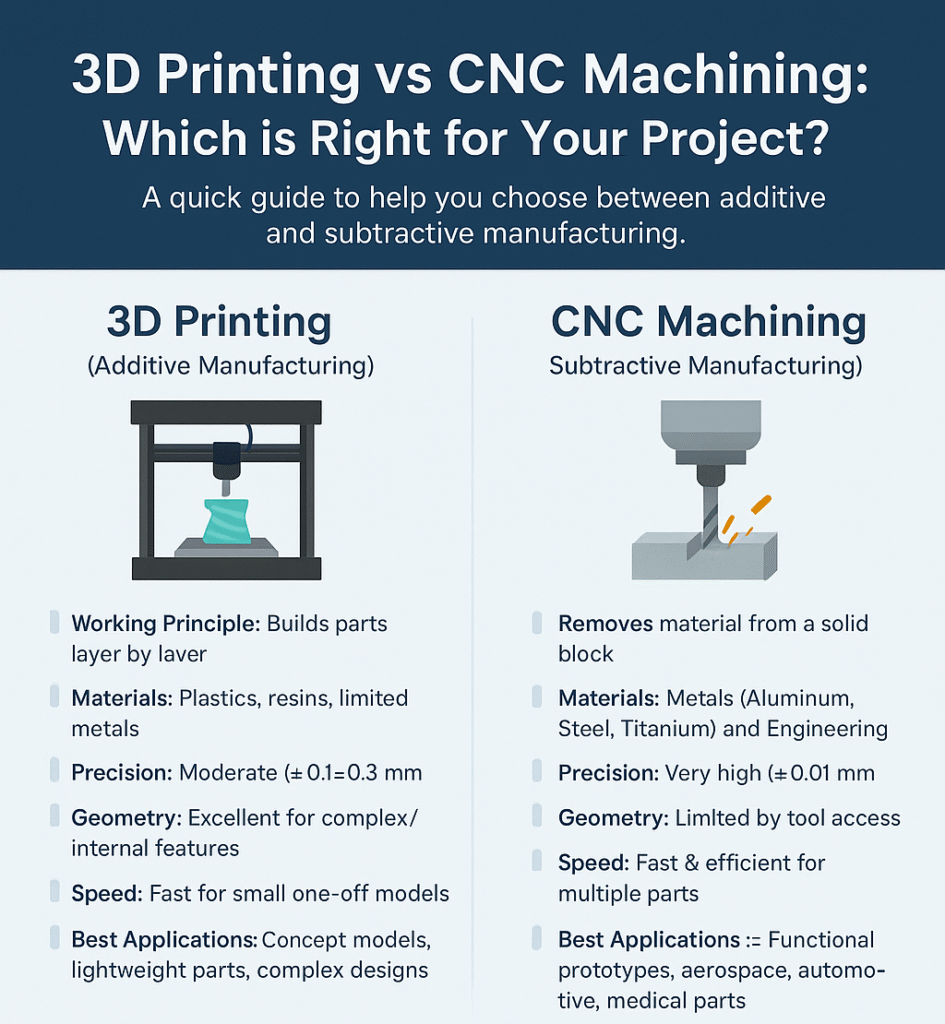

CNC Machining vs. 3D Printing: The Ultimate Selection Guide for Engineers

At Samshion Rapid, our engineers are asked one question daily: “For this part, should I use CNC machining or 3D printing?” The answer is never black and white. It hinges on a complex equation balancing end-use, material properties, cost, and timeline. This guide cuts through the hype to give you the practical insights you need to make […]

CNC Prototype Machining: Fast, Accurate & Cost-Effective Prototyping Services

Computer Numerical Control (CNC) machining has completely reshaped the way modern manufacturing works. For over 70 years, it has been the backbone of precision engineering, making it possible to create reliable, accurate, and functional parts across almost every industry. Among its many applications, CNC prototype machining stands out as one of the most valuable. When […]

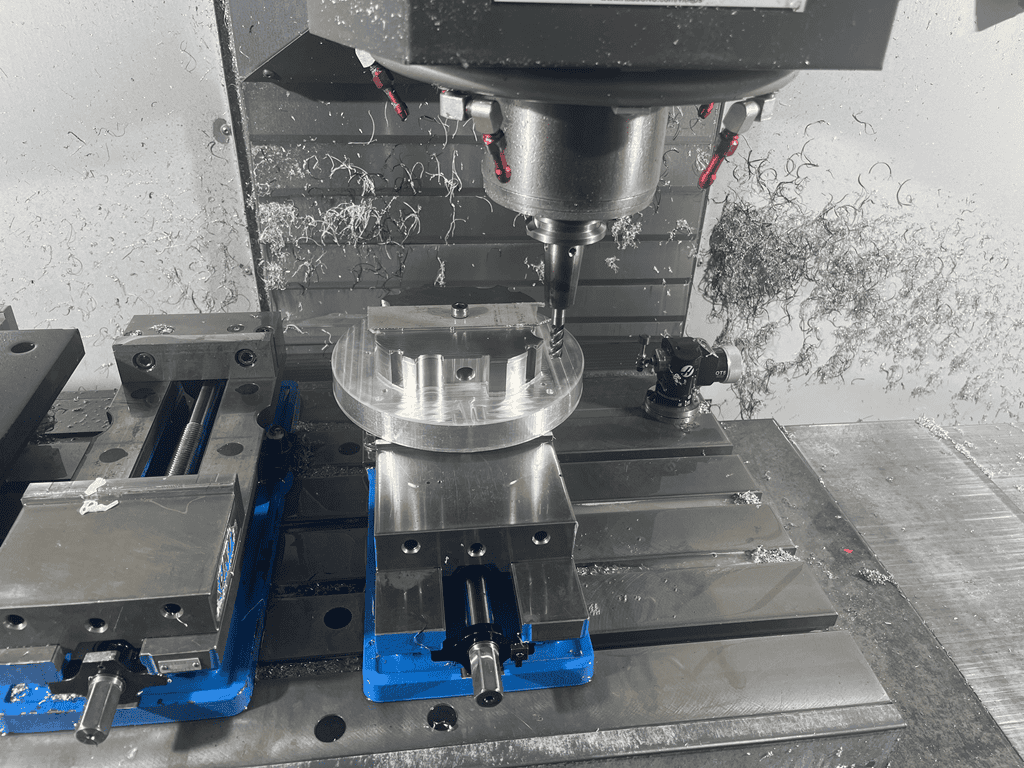

End Milling Guide: Techniques, Tools & Tips

Samshion Rapid’s production team takes pride in using end milling not just as another machining step—but as a core capability tailored to handle complex geometries and demanding surface finishes using our Haas CNC centers. When machining materials like stainless steel, aerospace alloys, or engineering-grade plastics, we precisely control every cut—only removing material where needed. This […]