The “Tolerance Stack-up” Nightmare: Why Your CNC Prototypes Don’t Fit Together

Introduction: When Perfect Parts Refuse to Assemble I believe as customers, you may have encountered similar ‘nightmares’. You have received a batch of CNC prototypes, and the shipping report looks flawless. Each key dimension is highlighted in green, each hole is precisely positioned according to the modeling, and each individual component is strictly within its […]

CNC Fixturing & Setup: Why Low-Volume Prototyping Costs So Much Compared to Mass Production?

Introduction: The Cost Paradox in CNC Manufacturing For many hardware startups and procurement managers, the first quote for a custom project often leads to a “sticker shock” moment. It is the CNC Cost Paradox: why does a single prototype cost $500, while the exact same part costs only $15 in a mass-production run of 10,000 […]

Cost-Efficient PEEK Prototyping: Key Considerations for CNC Projects

What is PEEK and Why Does It Pose Unique Machining Challenges? We often receive inquiries from engineers asking why a PEEK part costs significantly more than one made of Aluminum or POM. The answer lies in the material’s extraordinary properties and the rigorous high-precision PEEK prototype machining standards required to process it. What is PEEK […]

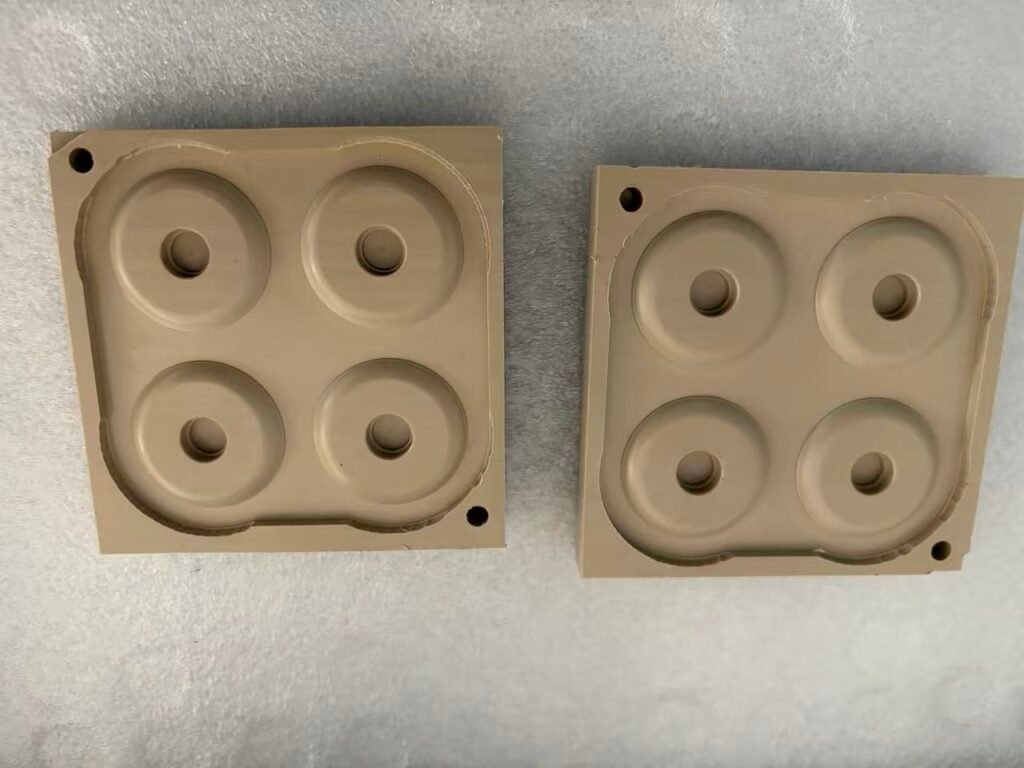

CNC Machining PA6 vs. PA66: Prototyping Guide and Technical Parameters

Introduction – Why PA6 and PA66 Matter in CNC Prototyping In the world of CNC prototyping plastics, Polyamide (Nylon) reigns supreme. Specifically, PA6 and PA66 are the “workhorse” materials for engineers who need to bridge the gap between a digital CAD model and a high-performance physical part. Why PA6 and PA66 Are the Go-To Materials […]

Rapid CNC Prototyping: How to Get Parts in 3 Days (Timeline)

Why Speed Matters in CNC Prototyping? In the high-stakes world of product development, the difference between a market leader and a follower often comes down to speed. Rapid CNC Prototyping isn’t just about getting a part quickly; it’s about maintaining the momentum of your entire project. When your team is facing critical milestones, every hour […]

Cast Iron CNC Machining: Achieving Precision & Controlling Wear

A Technical White Paper on Stability, Tooling, and Quality Control Executive Summary Despite the maturity of modern CNC technology, achieving consistent precision in cast iron machining remains a formidable engineering challenge. Cast iron is not a monolithic material; its heterogeneous nature—characterized by varying graphite structures and internal casting stresses—introduces volatility into the machining process. At […]

High-Precision 6061 Aluminum CNC Machining: Achieving ±0.005mm Tolerance

What is 6061 Aluminum CNC Machining? In the competitive landscape of modern manufacturing, 6061 aluminum has emerged as the premier choice for engineers and designers worldwide. Known for its exceptional versatility, it serves as the backbone of rapid prototyping and high-precision production. At Samshion Rapid, we leverage the unique properties of this alloy to deliver […]

304 Stainless Steel CNC Machining: Critical Parameters, Tooling & Finish Requirements

304 stainless steel is one of the most widely used materials in CNC machining due to its excellent corrosion resistance, mechanical strength, and machining versatility. As the workhorse material of stainless steel CNC machining, 304 stainless steel is commonly applied in precision components across medical, aerospace, automotive, and industrial equipment industries. At Samshion Rapid, we […]

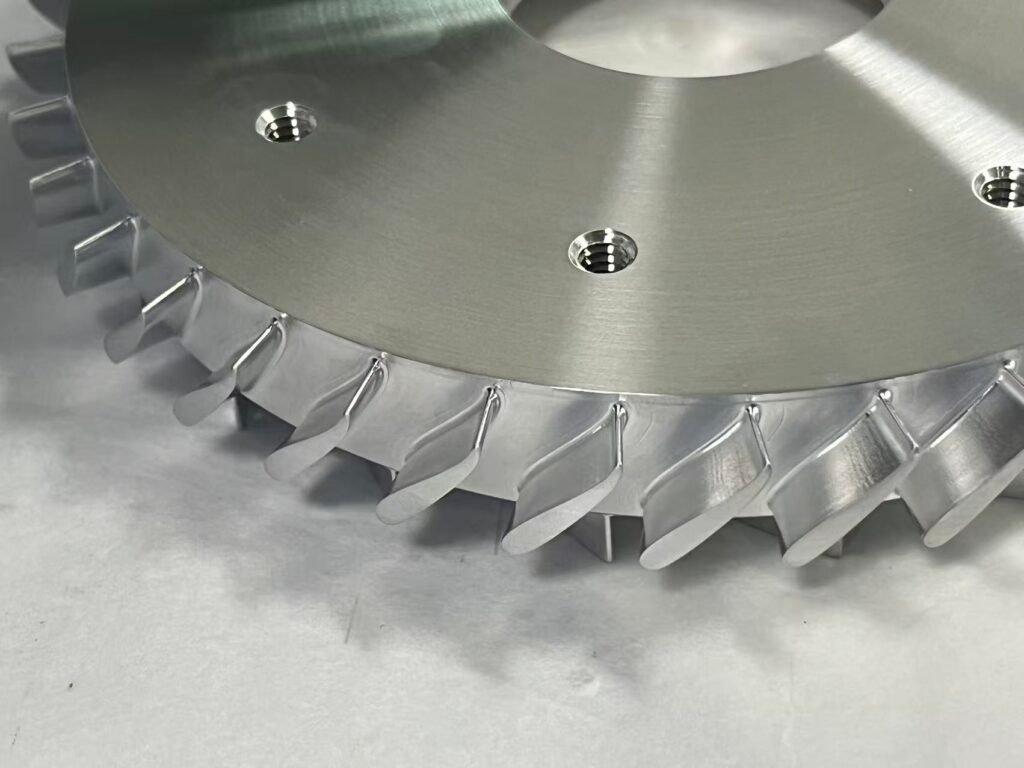

5-Axis CNC Machining: Why We No Longer Fear Complexity (No More Limits)

What is the Strategic Value of Five-Axis Machining? Five-axis machining represents a major advancement in modern CNC manufacturing, enabling the efficient production of highly complex and precision-critical components. By allowing simultaneous motion along five independent axes—three linear and two rotational—this technology overcomes the geometric and economic limitations of traditional three-axis machining. Originally developed in the […]

Machining PPS Guide: From Ryton Properties to Functional Prototypes

PPS (Polyphenylene Sulfide) is a top-tier engineering thermoplastic commonly employed in CNC machining because of its thermal resistance, chemical durability, dimensional precision and mechanical robustness. In large-scale CNC machining ore prototype production, PPS has gained popularity as a preferred material for reliable components, across aerospace, automotive, electronics, semiconductor machinery and industrial sectors.Samshion Rapid utilizes its […]