In today’s fast-paced manufacturing world, CNC machining has become the backbone of precision engineering. From aerospace components to medical devices, this technology transforms raw materials into intricate parts with unmatched accuracy. But what exactly is CNC machining, and why does it dominate modern production? Let’s explore its mechanics, advantages, and evolving role in Industry 4.0.

Understanding CNC Machining

CNC (Computer Numerical Control) machining is a digital manufacturing technology renowned for its precision, accuracy, and ability to produce complex geometries. Unlike manual operations, CNC uses microcomputers attached to machine tools to execute pre-programmed G-code and M-code instructions derived from CAD models. Through automated processes like milling, turning, and drilling, material is systematically removed from a workpiece to create finished parts.

Brief History of CNC Technology

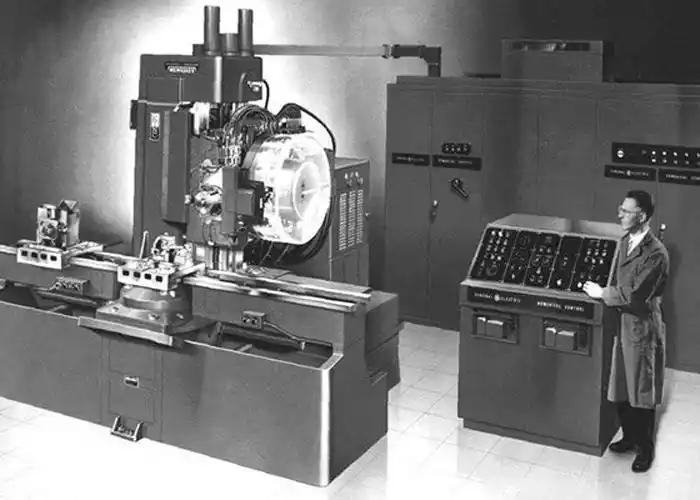

Before the digital era, parts were crafted manually or using mechanically operated machines, limiting precision, complexity, and scalability. The first breakthrough came in the 1940s when John T. Parsons collaborated with MIT to develop numerical control (NC) machines for the U.S. Air Force. These early systems relied on punch cards to direct tools but still required operator oversight.

The advent of faster computers in the 1970s revolutionized the field, replacing punch cards with digital code. Modern CNC systems now achieve speeds and accuracies unimaginable to their predecessors, enabling mass production of high-tolerance components.

The 4-Step CNC Machining Process

Step 1: CAD Model Preparation

Engineers design 2D or 3D models using software like AutoCAD or SolidWorks. Critical features—tolerances, threads, and structural lines—are highlighted to guide machining. Complex designs often convert 2D sketches into 3D models for clarity.

Step 2: Conversion to CNC-Compatible Format

CAD models are translated into G-code via CAM software (e.g., Fusion 360). This code dictates toolpaths, spindle speeds, feed rates, and cutting sequences, ensuring the machine interprets geometric data accurately.

Step 3: Machine Setup

Operators load G-code into the CNC system, configure tools (end mills, drills), and secure the workpiece. Parameters like coolant flow and tool alignment are calibrated based on material and design complexity.

Step 4: Automated Production

The CNC machine executes operations with minimal human intervention. Post-processing inspections verify dimensional accuracy and surface finish, ensuring alignment with the original CAD model.

Types of CNC Machines by Axis Configuration

The capabilities of CNC machines are largely defined by their axis configurations, which determine how the cutting tool and workpiece move relative to each other. More axes enable greater flexibility, precision, and the ability to produce complex geometries. Below, we break down the most common CNC machines based on their axis configurations, their unique advantages, and typical use cases.

1. 2-Axis CNC Machines

How They Work:

2-axis machines operate along two linear axes: X (horizontal) and Z (vertical). The workpiece rotates on a spindle (like a lathe), while the cutting tool moves linearly to perform operations such as facing, grooving, or threading.

Key Features:

Simplicity: Ideal for basic cylindrical or conical parts.

Cost-Effective: Lower initial investment and maintenance.

Speed: High production rates for simple geometries.

Applications:

Shafts, bolts, and bushings.

Mass production of symmetrical parts like bottle caps or pulleys.

Limitations:

Cannot handle complex contours or multi-sided machining.

2. 3-Axis CNC Machines

How They Work:

3-axis machines add the Y-axis, enabling movement in three linear directions (left/right, forward/backward, up/down). The workpiece remains stationary, while the cutting tool performs all motions.

Key Features:

Versatility: Suitable for milling slots, drilling holes, and cutting sharp edges.

Widely Used: The most common configuration for general-purpose machining.

Applications:

Engine blocks, mold cavities, and aluminum brackets.

Prototyping and low-to-medium complexity parts.

Limitations:

Requires manual repositioning for multi-angle features, increasing setup time.

Struggles with undercuts or deep cavities.

3. 4-Axis CNC Machines

How They Work:

4-axis machines introduce a rotational axis (A-axis), allowing the workpiece to spin horizontally. This enables machining on multiple faces without manual intervention.

Key Features:

Multi-Sided Machining: Ideal for parts requiring angular cuts or engraved patterns.

Faster Production: Reduces repositioning time compared to 3-axis.

Applications:

Camshafts, helical gears, and turbine blades.

Sculptural art pieces or architectural models with curved details.

Example:

A 4-axis CNC mill can machine all sides of a cube-shaped aerospace bracket in a single setup, ensuring perfect alignment of bolt holes and grooves.

4. 5-Axis CNC Machines

How They Work:

5-axis machines combine three linear axes (X, Y, Z) with two rotational axes (A and B or A and C). The cutting tool can approach the workpiece from any direction, enabling simultaneous multi-plane machining.

Key Features:

Unmatched Precision: Achieves tolerances as tight as ±0.001 mm.

Complex Geometries: Machines organic shapes, undercuts, and deep cavities in one setup.

Reduced Waste: Minimizes material repositioning errors.

Applications:

Aerospace components (e.g., turbine blades, impellers).

Medical implants (e.g., titanium spinal rods, dental prosthetics).

Automotive molds for complex intake manifolds.

Example:

A 5-axis CNC mill producing a jet engine turbine blade can complete all contours, cooling holes, and root fixtures in a single operation, eliminating alignment errors caused by multiple setups.

Why Invest in 5-Axis?

Time Savings: 60% faster than 3-axis for complex parts.

Surface Finish: Smoother results due to continuous tool engagement.

Design Freedom: Enables lightweight, topology-optimized parts.

Beyond 5-Axis: Multi-Tasking Machines

Modern CNC systems like 7-axis or 9-axis machines integrate additional functionalities such as automatic tool changers, robotic arms, or inline inspection probes. These “done-in-one” systems are used in high-volume industries like automotive for tasks like turning, milling, and laser engraving in a single cycle.

Choosing the Right Axis Configuration

| Factor | 2-Axis | 3-Axis | 4-Axis | 5-Axis |

|---|---|---|---|---|

| Complexity | Low | Moderate | High | Very High |

| Cost | 10k–10k–50k | 50k–50k–150k | 150k–150k–300k | 300k–300k–1M+ |

| Lead Time | 1–3 days | 3–7 days | 7–14 days | 14–30 days |

| Best For | Simple | Standard | Multi-angle | Aerospace/Medical |

Industry Spotlight: 5-Axis Dominance in Aerospace

In aerospace manufacturing, 5-axis CNC machining is indispensable. For instance, Boeing’s 787 Dreamliner uses 5-axis-machined titanium bulkheads that reduce weight by 20% while maintaining structural integrity. Similarly, SpaceX’s Raptor engine components rely on 5-axis systems to achieve the precise fuel channels needed for reusable rocket technology.

Future Trends in Multi-Axis Machining

AI-Powered Toolpaths: Machine learning algorithms optimize cutting angles and speeds dynamically.

Collaborative Robotics: Cobots assist in loading/unloading 5-axis machines, boosting productivity.

Nanoscale Precision: Emerging 7-axis systems target semiconductor and optical industries.

Key CNC Machining Operations Explained

CNC machining encompasses various subtractive processes tailored to specific geometries and materials. Below, we explore critical operations in detail, including their mechanisms, applications, and industry benchmarks.

1. CNC Drilling

Process Overview:

CNC drilling uses rotating drill bits to create precise cylindrical holes in workpieces. The machine positions the bit perpendicular to the material, applying axial force to penetrate surfaces.

Technical Parameters:

Speed: 500–3,000 RPM (varies by material hardness).

Coolant: Emulsified oils for heat dissipation in metals.

Tolerance: ±0.05 mm for standard holes.

Applications:

Automotive: Engine block bolt holes.

Electronics: PCB via holes for circuit connections.

Construction: Structural steel beam rivet holes.

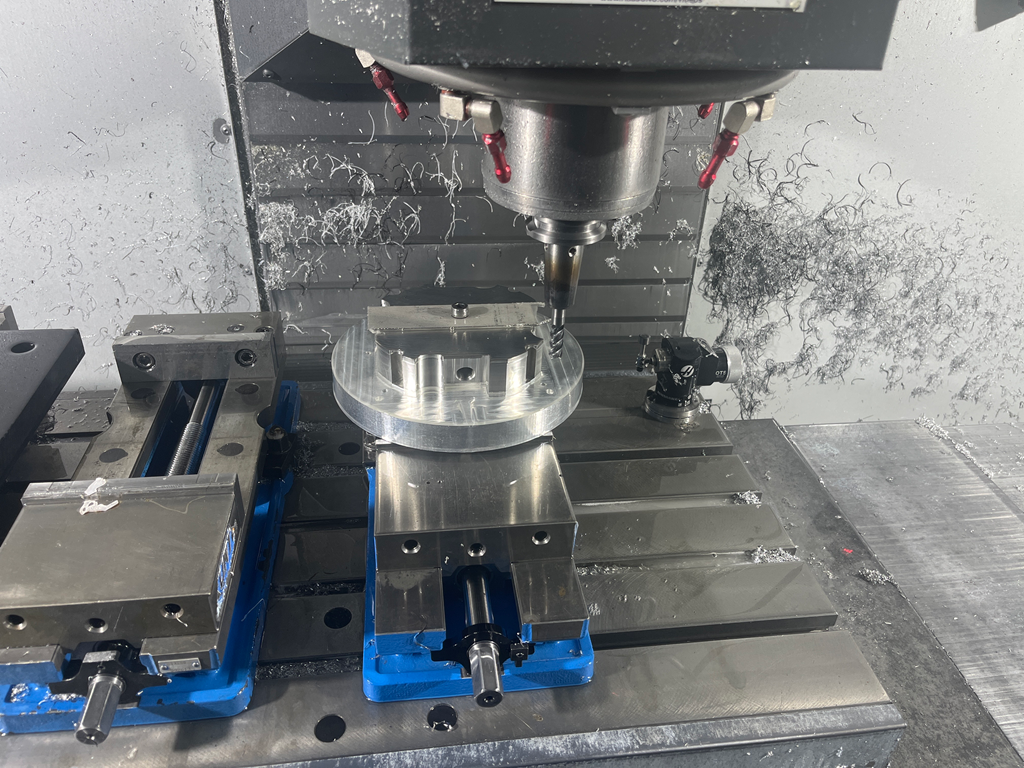

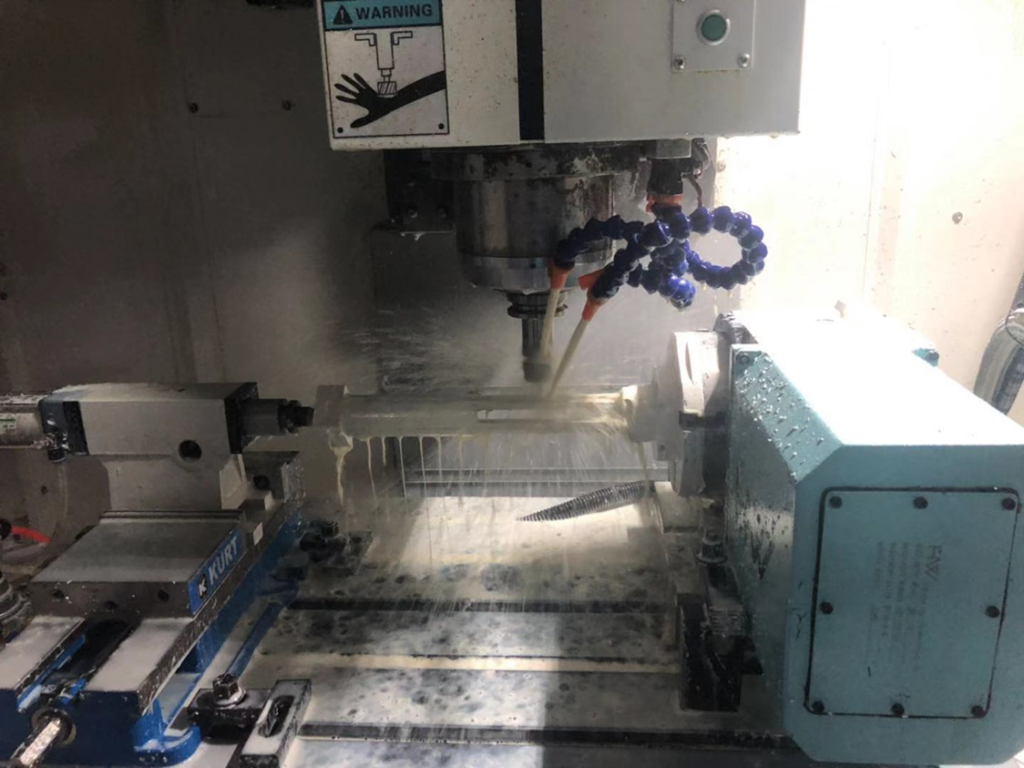

2. CNC Milling

Process Overview:

Milling employs multi-point cutting tools to remove material from a stationary workpiece. The tool rotates at high speeds while moving along programmed paths.

Types of Milling:

Face Milling: Flat surfaces (e.g., mold bases).

Profile Milling: Contoured edges (e.g., turbine blades).

Pocket Milling: Internal cavities (e.g., smartphone casings).

Technical Parameters:

Spindle Speed: 1,000–50,000 RPM (carbide tools for metals).

Feed Rate: 200–1,200 mm/min (dependent on material).

Surface Finish: Ra 0.4–3.2 μm (as-machined).

Applications:

Aerospace: Wing rib components with complex airfoil shapes.

Medical: Titanium bone plates with threaded screw holes.

3. CNC Turning

Process Overview:

Turning rotates the workpiece while a stationary cutting tool removes material to create cylindrical parts. Ideal for shafts, pins, and bushings.

Technical Parameters:

Chuck Speed: 50–3,500 RPM (steel vs. plastics).

Depth of Cut: 0.1–5 mm per pass.

Tolerance: ±0.025 mm for precision bearings.

Applications:

Oil & Gas: Stainless steel valve stems.

Consumer Goods: Aluminum alloy flashlight bodies.

4. Electrical Discharge Machining (EDM)

Process Overview:

EDM uses controlled electrical sparks to erode conductive materials. The workpiece and electrode are submerged in dielectric fluid to manage heat and debris.

Types:

Wire EDM: Cuts intricate shapes with 0.02–0.3 mm brass wire.

Sinker EDM: Shapes cavities using graphite/copper electrodes.

Technical Parameters:

Spark Gap: 0.01–0.05 mm.

Surface Finish: Ra 0.2–0.8 μm (mirror-like finishes).

Applications:

Tool & Die: Injection molds for plastic packaging.

Aerospace: Cooling holes in nickel superalloy turbine blades.

Advantage:

EDM machines hardened steels (up to 65 HRC) without inducing thermal stress, critical for tool longevity.

CNC Material Selection Guide

Choosing the right material is pivotal for performance and cost-efficiency. Below, we analyze top materials across categories:

| Material | Properties | Applications | Machining Tips |

|---|---|---|---|

| Aluminum 6061 | Lightweight, corrosion-resistant | Drones, automotive frames | Use sharp carbide tools; avoid built-up edge. |

| Stainless Steel 316 | Medical-grade, non-reactive | Surgical instruments, marine hardware | Low feed rates to prevent work hardening. |

| PEEK | High-temperature polymer (260°C max) | Aerospace bushings, sterilization trays | Coolant required to prevent melting. |

| Titanium Ti6Al4V | Strength-to-weight ratio (4.43 g/cm³) | Aircraft landing gear, implants | Low RPM, high feed rates to manage heat. |

| Carbon Fiber | High stiffness, lightweight | Racing car components, UAV arms | Diamond-coated tools to reduce fraying. |

CNC Software Ecosystem

Modern CNC workflows rely on integrated software solutions for design, simulation, and production:

1. CAD Software

SolidWorks: Parametric modeling for complex assemblies.

AutoCAD: 2D drafting and basic 3D modeling.

Blender: Open-source tool for artistic prototypes.

2. CAM Software

Fusion 360: Cloud-based toolpath generation with AI optimization.

Mastercam: Industry standard for multi-axis programming.

GibbsCAM: Specialized in mill-turn and Swiss-type machining.

3. CAE Software

ANSYS: Finite element analysis (FEA) for stress testing.

Simufact: Simulates metal forming and heat treatment effects.