Precision CNC Milling Services

This may be the most end-to-end protected milling service you have ever encountered.

At Samshion, even if it’s concept sketches, rough ideas, or precision designed components, we have a mature quality control system and a professional engineering team to provide support for each production stage, transforming your unique design into tangible industrial art.

- Ultra Strict Tolerance: achieving as low as ±0.0005 inches (0.01 mm).

- Multi Functionality Of Materials: over 100 types of metals, plastics, and composite materials.

- Excellence Certification: Compliant with ISO 9001:2015 standard.

- Speed You Can Trust: Prototypes in 1 day and production batches in 3-5 days.

- High Quality Finish: Selected 50+surface treatments to meet aesthetic and functional requirements.

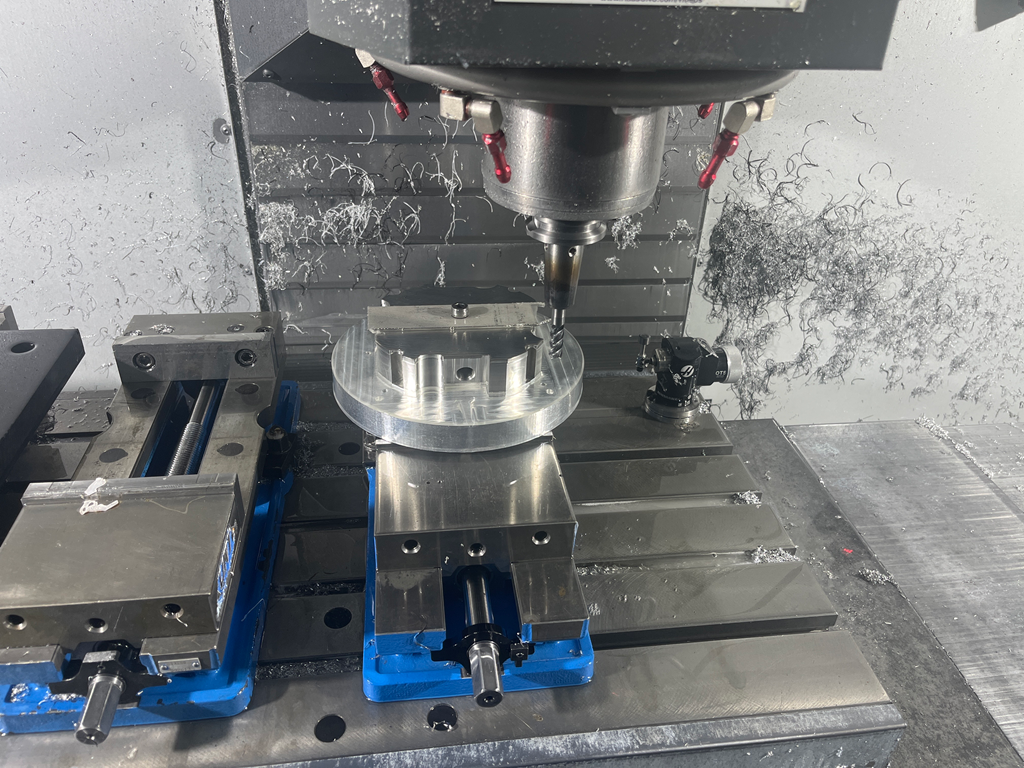

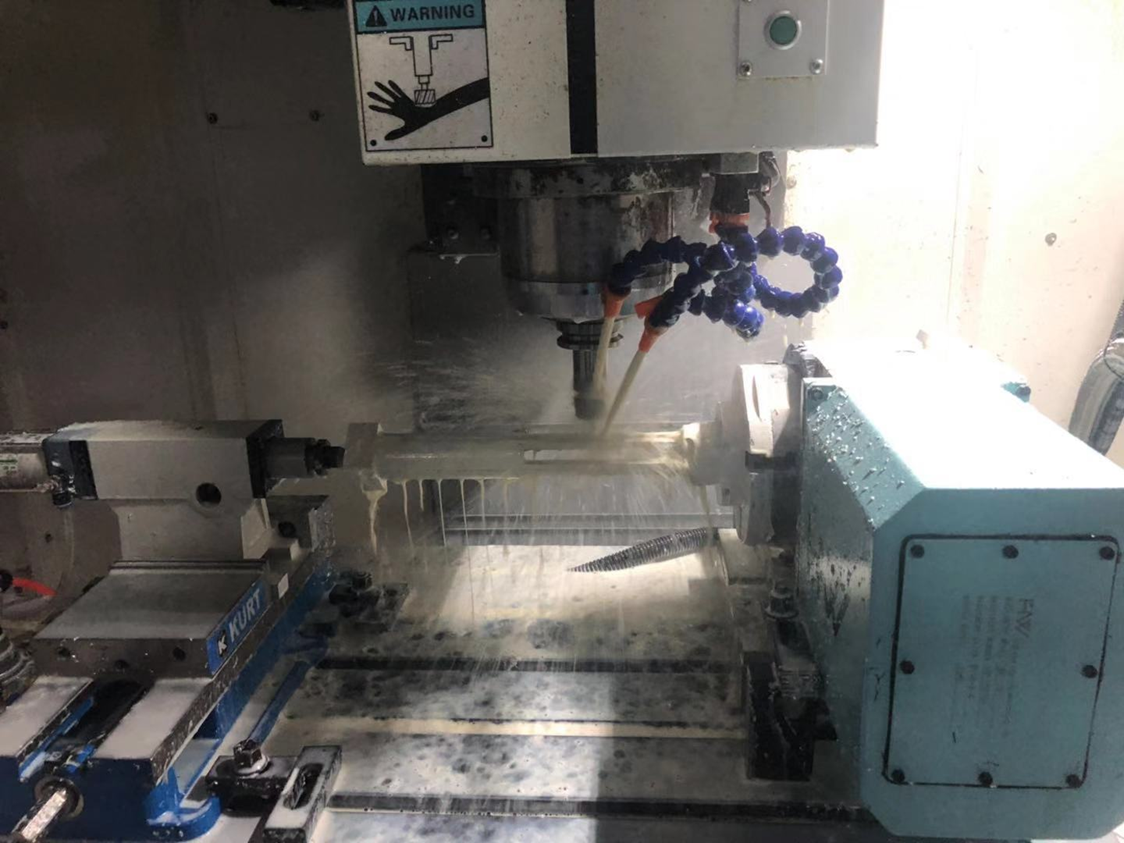

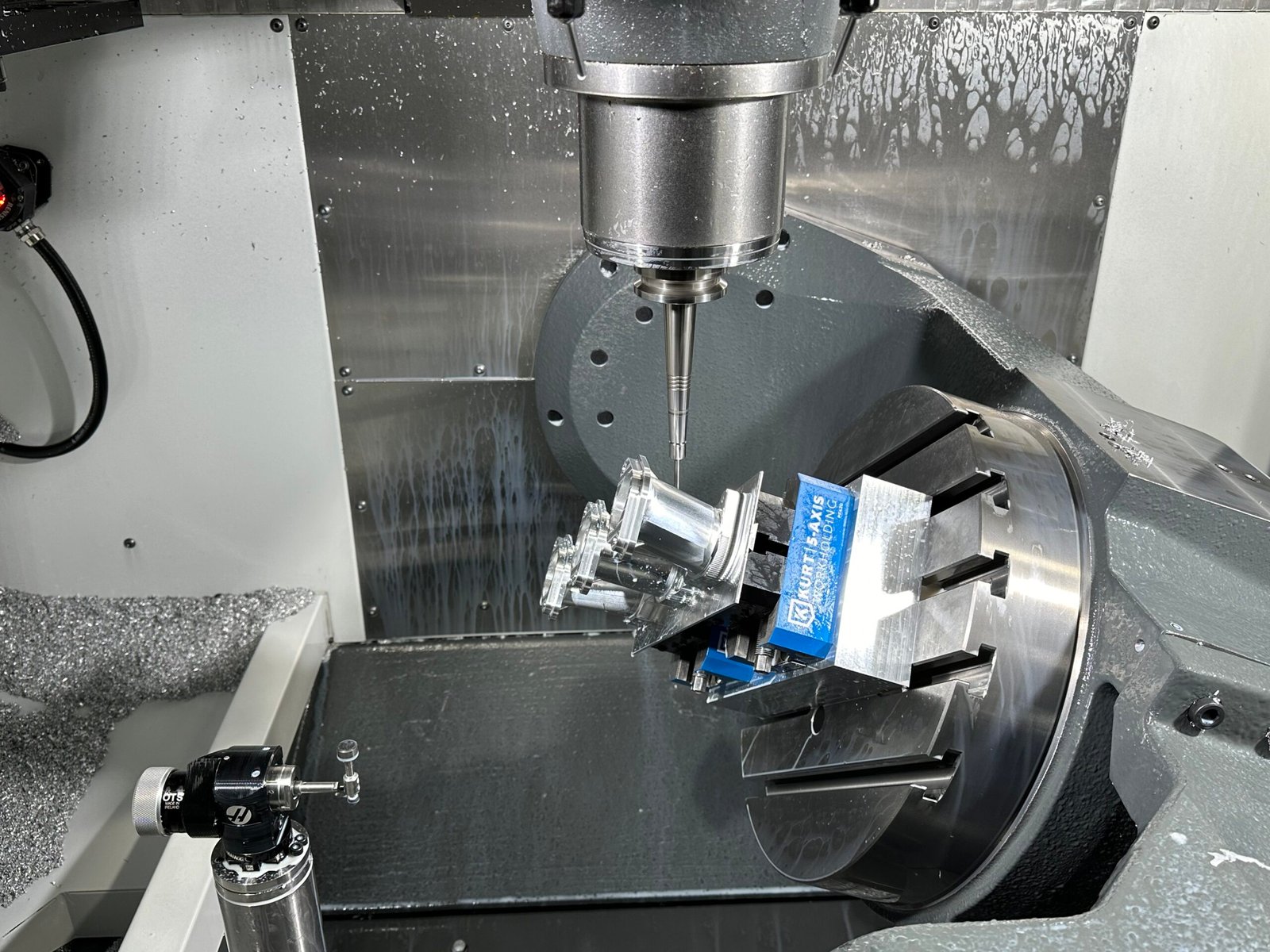

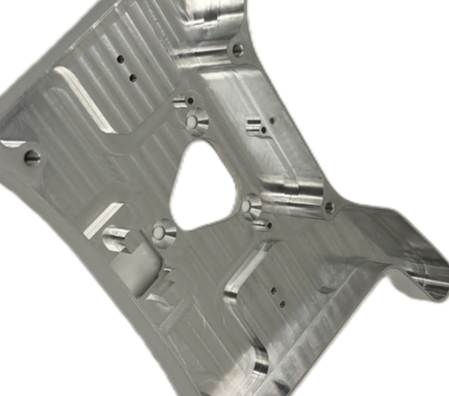

Custom CNC Milling Services | Precision Parts with 3, 4 & 5-Axis Machining

At Samshion, we provide CNC milling solutions and our engineering team is always ready to solve problems. Whether it’s your parts that are difficult to machine due to an unreasonable structure or require some innovative design ideas, we can provide DFM solutions or design services. Tailored specifically for custom parts, utilizing advanced 3-axis, 4-axis, and 5-axis CNC machines, we produce strict tolerance components in metal, plastic, and composite materials for the aerospace, medical, automotive, and industrial sectors.

3-Axis CNC Milling Service

Cost-effective for simple prototypes and basic geometries requiring dimensional accuracy and efficiency.

4-Axis CNC Milling Service

Optimized for parts with sidewall features, elongated designs, and slots. Faster setups and improved surface finishes over 3-axis milling.

5-Axis CNC Milling Service

Ideal for complex parts with multi angle features,undercuts and aerospace grade accuracy, such as impellers and rocket launcher components. Can provide improved efficiency and accelerate time to market.

Why Choose Samshion?

Partnering with Samshion for CNC milling means more than just precision machining — it’s a promise of reliability, speed, and expert support. We combine advanced equipment with strict quality control to deliver superior results for every project.

- ISO 9001 Certified: Quality-driven processes for aerospace, automotive, and medical industries.

- Free DFM Analysis: Optimize your design for manufacturability and cost efficiency.

- 24/7 Support: Expert engineers ready to resolve technical queries.

High-Precision Machining

Samshion deliver components with tolerances up to ±0.005 mm, ensuring reliable fit and perfect functionality regardless of the demanding requirements of the product’s application scenarios.

Fast & Flexible Lead Times

In-house workshops and agile workflows allow us to meet urgent deadlines, from rapid prototypes to full-scale production runs.

End-to-End Engineering Support

Our expert engineers provide DFM advice, material selection guidance, and continuous support to optimize your CNC milling projects.

Rapid & Scalable Manufacturing

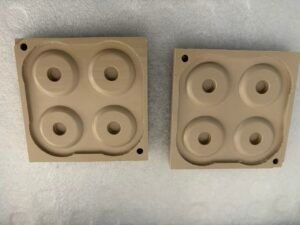

Custom CNC Prototyping & Production Services

Our rapid prototyping service is very suitable for validating new designs, as conceptual designs may often have some differences from real products. We shorten the development cycle and ensure production readiness accuracy by testing prototype functionality and manufacturability analysis.

Request a quote immediately to expedite the time to market.

Rapid Prototyping

Rapid prototyping services can quickly turn your idealized products into reality and validate functionality to analyze mass production possibilities. We can even provide DFM optimization solutions.

Low and High-Volume Production

We analyze and select cost-effective solutions to seamlessly expand your CNC small batch (50-5000 units) and large-scale production. Small batch products can be directly CNC machined into high-precision (0.005mm) products, while large batch products can choose manufacturing molds based on product materials and characteristics.

CNC Milling Materials: Metals & Plastics for Precision Machining

At Samshion, we use CNC or mold to shape various materials to meet your customized manufacturing needs. Comprehensive material selection ensures optimal machinability, precision, and surface finish quality.

Material Testing & Compliance

In order to ensure the quality and compliance of materials, we use advanced material analysis instruments (XRF) for rigorous material validation in our internal laboratory. And we will provide complete material proof.

Metal Materials

We offer CNC machining for a full spectrum of metals, including:

Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper, Magnesium Alloy, Titanium Alloy, and Zinc Alloy.

Ideal for high-strength, heat-resistant, and corrosion-resistant applications.

Plastic Materials

Our CNC machining capabilities extend to engineering-grade plastics such as:

ABS, PC, PMMA (Acrylic), PA (Nylon), PA+GF30, POM (Acetal / Delrin), PP, PVC, HDPE, PPS, PEEK, PEI (Ultem), Teflon, Bakelite Resin, and Epoxy Tooling Board.

Perfect for lightweight, chemical-resistant, and cost-effective components.

Description:

Aluminum alloys are engineered metallic materials composed primarily of aluminum combined with elements such as copper, magnesium, silicon, or zinc. Renowned for their exceptional strength-to-weight ratio, corrosion resistance, and versatility, aluminum alloys are widely used across industries ranging from aerospace to consumer electronics.

Alloys:

6061-T6, 7075-T6, 7050, 2024, 2A12,6082,5083,5052, 6063, MIC6.etc.

Finishing Options:

Alodine, Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing.

Description:

Stainless steel is a corrosion-resistant iron-based alloy containing a minimum of 10.5% chromium, combined with elements like nickel, molybdenum, and carbon. Renowned for its durability, aesthetic versatility, and hygienic properties, stainless steel is a cornerstone material in industries ranging from medical devices to architectural design.

Alloys:

303, 304L, 316L, 410, 416, 440C, 17-4PH, Nitronic 60.etc.

Finishing Options:

Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Black Oxide, Zinc Plating, Vibratory Tumbling.

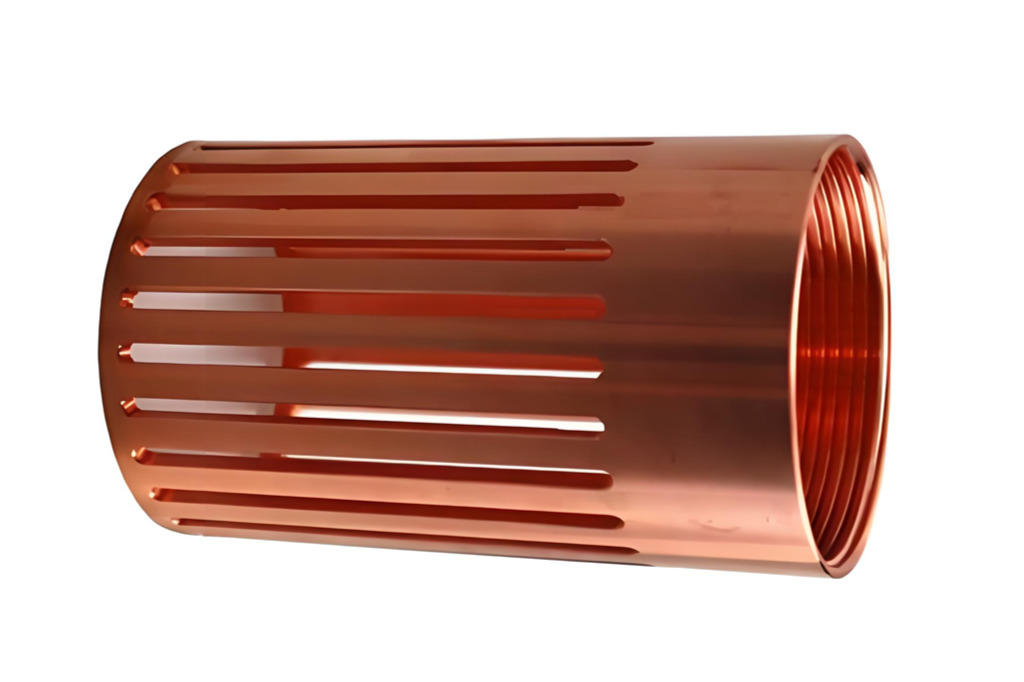

Description:

Copper, a ductile and malleable metal with exceptional electrical and thermal conductivity, is a cornerstone of modern technology and industrial applications. Known for its natural reddish-brown hue, corrosion resistance, and recyclability, copper and its alloys are indispensable in sectors ranging from electronics to renewable energy.

Alloys:

C1100,C1011.etc.

Finishing Options:

Media Blasting, Nickel Plating, Passivation, Tumble Polishing, Vibratory Tumbling.etc.

Description:

Brass alloys are versatile metallic materials primarily composed of copper and zinc, often enhanced with elements like lead, tin, or aluminum. Known for their excellent machinability, corrosion resistance, and aesthetic appeal, brass alloys are widely utilized in industries such as plumbing, musical instruments, decorative hardware, and electrical components.

Alloys:

C260, C360, C464, C485, C280, C220, C230, C510, C544, C675.

Finishing Options:

Polishing, Electroplating (Nickel, Chrome), Clear Lacquering, Antiquing, Powder Coating, Passivation, Sandblasting, Brushed Finish, Hot-Dip Galvanizing, Laser Etching.

Description:

Steel alloys are engineered metallic materials primarily composed of iron and carbon, often enhanced with elements like chromium, nickel, or molybdenum. Renowned for their exceptional strength, durability, and resistance to wear and corrosion, steel alloys are extensively used in industries such as construction, automotive manufacturing, industrial machinery, and tooling.

Alloys:

1045 Carbon Steel, A36 Mild Steel, 4140 Chromoly Steel, 4340 High-Strength Steel, D2 Tool Steel, A2 Tool Steel, 52100 Bearing Steel, 8620 Case-Hardening Steel.

Finishing Options:

Heat Treatment (Quenching, Tempering), Galvanizing, Powder Coating, Electroplating (Nickel, Chrome), Media Blasting, Passivation, Polishing, Black Oxide Coating, Anodizing, Laser Engraving.

Description:

Titanium alloys are advanced metallic materials primarily composed of titanium blended with elements like aluminum, vanadium, or nickel. Renowned for their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, titanium alloys are critical in high-performance industries such as aerospace, medical implants, marine engineering, and chemical processing.

Alloys:

Ti-6Al-4V (Grade 5), Ti-3Al-2.5V (Grade 9)

Finishing Options:

Anodizing (Type II, III), Media Blasting, Electropolishing, Passivation, Thermal Oxidation, PVD Coating, Laser Marking, Chemical Etching, Powder Coating, Grinding/Polishing.

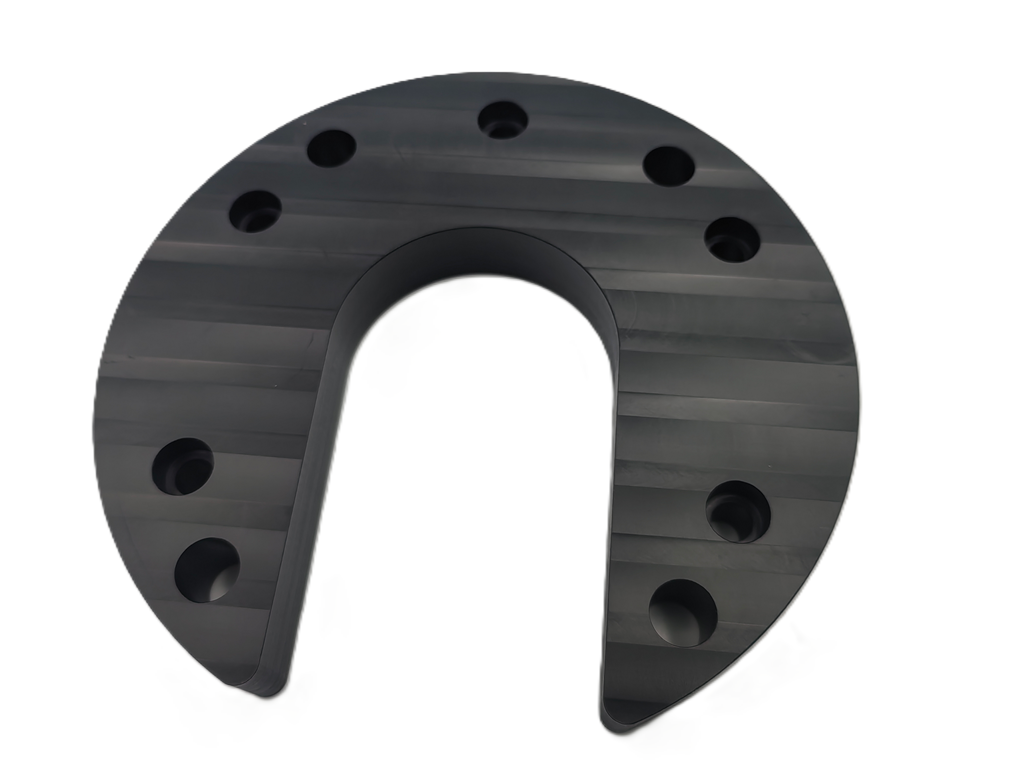

Description:

Magnesium alloys are lightweight metallic materials primarily composed of magnesium combined with elements such as aluminum, zinc, or manganese. Renowned for their exceptional strength-to-weight ratio, vibration damping properties, and machinability, magnesium alloys are widely utilized in high-performance industries including aerospace, automotive lightweighting, consumer electronics, and biomedical devices.

Alloys:

AZ31B, AZ91D,

Finishing Options:

Anodizing (Type I, II), Chemical Conversion Coating (Chromate, Phosphate), Electroplating (Nickel, Copper), Powder Coating, Laser Etching, Passivation, Polishing, PVD Coating, Epoxy Sealing, Thermal Spraying.

Description:

ABS (Acrylonitrile Butadiene Styrene) is a versatile thermoplastic polymer celebrated for its excellent impact resistance, thermal stability, and ease of processing. Combining rigidity, surface gloss, and electrical insulation properties, ABS is extensively utilized in automotive parts, consumer electronics, household appliances, toys, and industrial piping systems.

Colors:

Opaque beige, Black.

Finishing Options:

As machined, Media blasting, Polishing, Painting, Texture coating, Clear lacquering, Electroplating

Description:

POM (Polyoxymethylene) is a high-performance engineering thermoplastic renowned for its exceptional mechanical strength, low friction coefficient, superior dimensional stability, and resistance to chemicals. With outstanding wear resistance and anti-creep properties, POM is widely used in precision mechanical components, gears, bearings, electronic connectors, medical devices, and automotive systems.

Colors:

White, Black.

Finishing Options:

As machined, Media blasting, Polishing,

Description:

Nylon is thermoplastic with high strength, wear resistance, excellent sound/vibration dampening, and low friction coefficient. It is commonly used in engineering and manufacturing processes. Common applications include gears, bearings, and bushings. Two of the most notable use cases for Nylon are in medical devices and electronics insulation, notably screws and spacers for panel mounted circuit boards.

Colors:

Opaque beige, Black.

Finishing Options:

As machined, Media blasting, Polishing,

Description:

PEEK, (polyether ether ketone) is a thermoplastic widely used in industries such as aerospace, automotive, and electronics. PEEK has high strength, stiffness, toughness, chemical, biocompatibility, and thermal resistance. Due to its , PEEK is also suitable for use in harsh environments where other materials may fail. Common applications include aircraft structures, electronic components that require high temperature resistance, and medical and dental components (including implantables).

Colors:

Opaque beige

Finishing Options:

As machined, Media blasting, Polishing,

Description:

PE is flexible, chemical-resistant, and impact-resistant.

Lightweight and cost-effective, this material is ideal for packaging, containers, and piping systems where durability and adaptability are essential.

Color:

Natural White,Black,

Finishing Options:

As machined, Sand blasting, Tumbling,

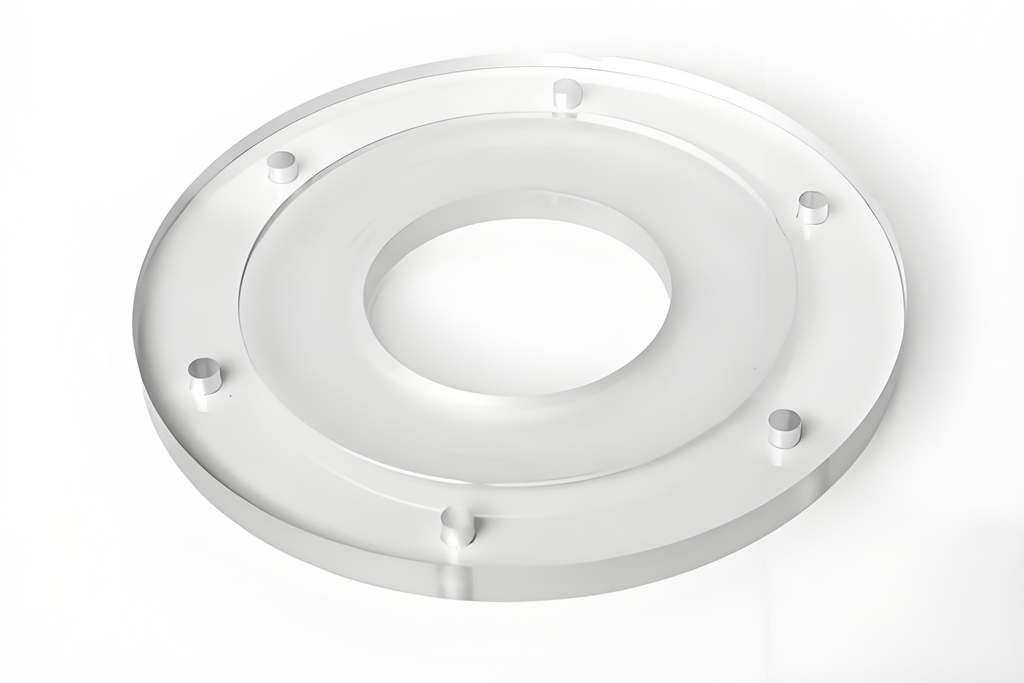

Description:

Polycarbonate (PC) is renowned for its exceptional clarity, high impact resistance, and thermal stability. Widely used in optical lenses, automotive components, and protective equipment, PC maintains structural integrity under stress while offering lightweight versatility.

Color:

Transparent,Black,

Finishing Options:

As machined, Media Blasting, Polishing, Anti-Scratch Coating, Painting, Textured Finish, Laser Etching

Description:

HIPS is lightweight, impact-resistant, and easy to machine.

Ideal for prototyping and consumer products, this material balances durability and cost-effectiveness while offering excellent surface finish for aesthetic applications.

Color:

Natural White,Black,

Finishing Options:

As machined, Media blasting, Polishing, Painting, Texture coating, Clear lacquering, Electroplating

CNC Surface Finishes for Precision-Machined Parts

At Samshion, we offer a variety of high-quality surface treatments aimed at enhancing the appearance, durability, and performance of CNC machined parts according to customer requirements. Our surface treatment solutions not only improve corrosion resistance or wear resistance, but also comply with strict industry standards.

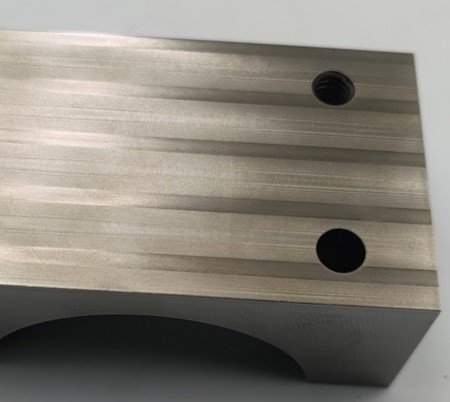

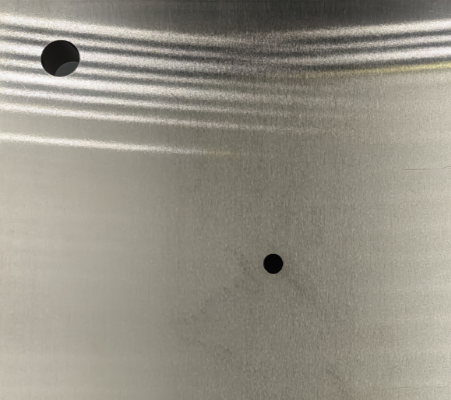

As Machined

The as-machined finish delivers parts directly from CNC machining, retaining minor tool marks for a cost-effective solution. Ideal for functional prototypes and non-critical components requiring no post-processing.

Anodizing

Anodizing enhances corrosion resistance, wear resistance, and aesthetics for aluminum parts. Custom colors and glossy finishes available.

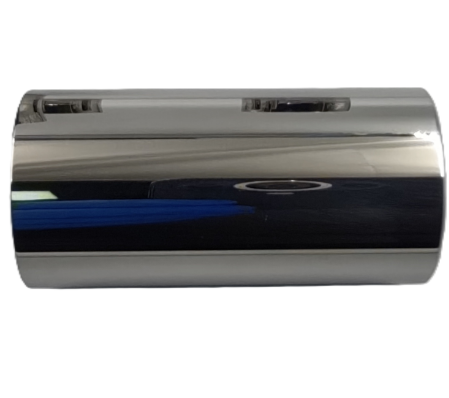

Polishing

Achieve a mirror-like finish with polishing, reducing surface roughness to Ra 0.2 µm. Perfect for luxury products and optical components.

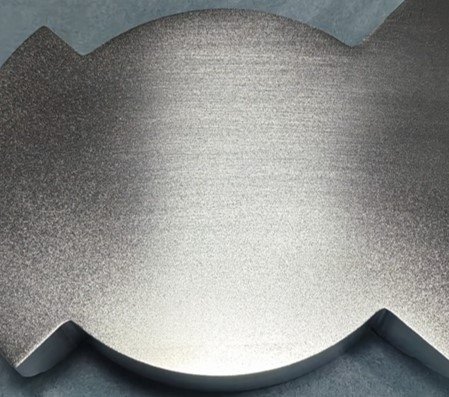

Sand Blasting

Sand blasting creates a uniform matte texture, hiding imperfections and improving paint adhesion. Uses pressurized media for consistent results.

Tumbling

Tumbling smooths edges and surfaces via friction in a rotating barrel, offering a slightly textured, uniform finish for small parts.

Electropolishing

Electropolishing chemically removes surface layers to enhance smoothness, brightness, and corrosion resistance. Ideal for stainless steel and medical devices.

Alodine

Alodine coating provides corrosion protection and paint adhesion for aluminum, with a conductive yellow film.

Heat Treatment

Heat treatment enhances metal properties like hardness, strength, or ductility in a controlled vacuum environment.

Brushed Finish

A brushed finish creates a unidirectional satin texture, masking scratches and adding aesthetic appeal.

Powder Coating

Powder coating applies a thick, wear-resistant polymer layer with vibrant color options and UV resistance.

Nickel Electroplating

Electroplating deposits a thin nickel layer for enhanced wear resistance, conductivity, and corrosion protection.

Black Oxide Coating

Black oxide forms a magnetite layer on ferrous metals, reducing glare and improving corrosion resistance.

Whether your project requires visual appeal, environmental protection, or enhanced mechanical properties, our custom CNC surface finishes are engineered to match your exact specifications.

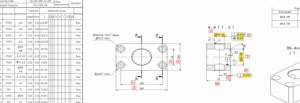

Standard Tolerances for Linear Dimensions (ISO 2768)

Values in millimeters

| Basic Size Range | Fine (±) | Medium (±) | Coarse (±) | Very Coarse (±) |

|---|---|---|---|---|

| 0.5 ≤ 3 | 0.05 | 0.1 | 0.2 | – |

| >3 ≤ 6 | 0.05 | 0.1 | 0.3 | 0.5 |

| >6 ≤ 30 | 0.1 | 0.2 | 0.5 | 1 |

| >30 ≤ 120 | 0.15 | 0.3 | 0.8 | 1.5 |

| >120 ≤ 400 | 0.2 | 0.5 | 1.2 | 2.5 |

| >400 ≤ 1000 | 0.3 | 0.8 | 2 | 4 |

| >1000 ≤ 2000 | 0.5 | 1.2 | 3 | 6 |

| >2000 ≤ 4000 | – | 2 | 4 | 8 |

Samshion’s CNC Milling Tolerance Standards

At Samshion, we adhere to ISO 2768 standards for precision:

- Plastic Parts: Medium tolerance (ISO 2768-M) for cost-effective production.

- Metal Parts: Fine tolerance (ISO 2768-F) for high-accuracy applications.

Typical Tolerance Ranges:

- Standard: ±0.005” (±0.127 mm)

- High Precision: ±0.002” (±0.05 mm)

For mission-critical components requiring tighter tolerances (e.g., ±0.001” or ±0.025 mm), submit a 2D engineering drawing with detailed specifications. Our engineering team will collaborate with you to optimize manufacturability and ensure flawless execution.

Part lengths of up to 40″ are available on our platform process dependent. Please inquire about anything larger. Tolerances listed here are minimums for an ideal case. Looser tolerances may be required depending on process, material choice, or part geometry.

Uncompromising Quality Assurance

At the heart of Samshion’s operations lies an uncompromising quality philosophy. Advanced spectroscopic technology can verify the characteristics of each batch of materials, while the 3D scanning system verifies that the dimensions meet micrometer level accuracy. The first article and process quality inspection resulted in a 99.3% first article acceptance rate. This rigorous process ensures our long-term partnership with customers, with 40% of customers returning repeat projects for five consecutive years, demonstrating our ability to strike a balance between speed, accuracy, and reliability.

Advanced Inspection Technology

We deploy cutting-edge equipment to guarantee unmatched precision:

- Coordinate Measuring Machines And 3D Scanners: Measurement standards for micrometer level dimensional accuracy

- XRF Analyzers: Verify material composition and ensure RoHS compliance.

- Optical Comparators And Micrometers: Checking surface smoothness and critical tolerances.

- Automatic Measurement System: Real-time monitoring for consistency.

End to end full process quality control

We have a professional team certified with ISO 9001:2015 and implement systematic testing at all stages of manufacturing:

- Pre Production Stage: Complete design feasibility analysis (DFM) and raw material qualification certification.

- Production Stage: Statistical process control (SPC) combined with real-time production inspection.

- Finished Product Stage: Functional testing, appearance inspection and performance compliance verification.

- Quality Documentation: FAI, PPAP and Compliance Certification Documents.

Trusted by Global Industries

With 20+ years of expertise, Samshion delivers:

- Zero Defect Guarantee: Based on the Six Sigma method, ensuring high quality.

- Quick Delivery: 3 days for prototype, 7 days for mass production.

- Full Traceability: Material certificates, testing reports and compliance documents.

CNC Milling Design Guidelines for Manufacturability & Cost Efficiency

At Samshion, our expert team provides real-time design feedback to improve your parts for optimal results, following validated Design for Manufacturability (DFM) best practices to help you shorten production cycles, avoid expensive redesigns, and achieve perfect CNC components.

Critical CNC Milling Design Considerations:

Key Benefits of Optimized CNC Designs

Reduce Costs: Avoid redesigns and tooling conflicts.

Speed Up Production: Streamlined designs enable 3-5 day lead times.

Ensure Quality: Achieve ±0.02 mm tolerances with ISO 9001-certified processes.

Radii & Internal Corners

Sharp internal corners in CNC machining naturally form rounded edges (radii). Adhere to these limits for tool longevity and precision:

Drill Depth: ≤12× drill diameter.

End Mill Depth: ≤10× tool diameter.

Design Tip: Avoid deep, narrow cavities to prevent tool deflection and maintain precision.

Threads & Tapped Holes

Achieve reliable threading with these specifications:

Small Threads (≤5 mm): Depth ≤3× diameter.

Large Threads (>5 mm): Depth ≤4-6× diameter.

Custom Solutions: Full support for metric, UNC, UNF, and special specifications.

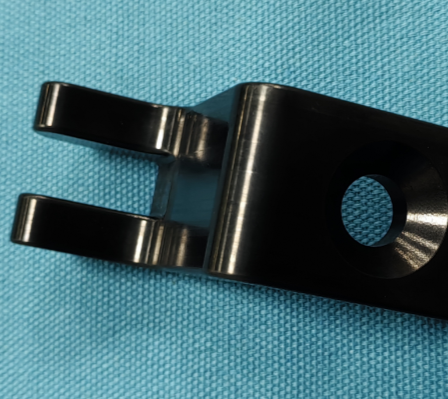

Undercuts

Design undercuts for seamless machining:

Types Supported: Square profiles, full-radius grooves, dovetail undercuts.

Best Practices:

Define undercut features clearly in CAD files.

Standardize tooling sizes to lower costs.

Simplify complex geometries in deep cavities.

Text & Engraving

Ensure legibility and durability for engraved text:

CNC Milling: Minimum 0.5 mm width and 0.1 mm depth.

CNC Turning: Laser marking for permanent, high-contrast results.

Options: CNC engraving or laser marking for fonts, logos, and symbols.

Frequently Asked Questions (FAQ)

1. What materials can be used for CNC milling?

We support a wide range of materials, including aluminum, stainless steel, brass, copper, titanium, PEEK, nylon, ABS, and many engineering plastics. Custom material requests are also available upon consultation.

2. What is the typical CNC milling tolerance?

Our standard tolerance is ±0.05mm. For high-precision components, we can achieve tolerances as tight as ±0.01mm, depending on material and geometry.

3. How long does CNC milling production take?

Lead times typically range from 3 to 10 business days, depending on part complexity, quantity, and surface finish requirements. Expedited services are available for urgent projects.

4. Can Samshion handle small-batch or prototype orders?

Absolutely. We specialize in both low-volume prototyping and mass production, providing flexible solutions tailored to your project needs.

5. What types of surface finishes do you offer?

We provide bead blasting, anodizing (Type II & III), powder coating, electroplating, brushing, polishing, and custom coatings to enhance appearance and performance.

6. How do you ensure the quality of machined parts?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

7. How can I get a quote for CNC milling services?

Simply upload your CAD files and specify materials, quantities, and surface finishes. Our engineers will provide a detailed quotation within 24 hours.