Custom Online 3D Printing Solutions

Receive real-time pricing for 3D printed components in plastics and metals. Produce high-quality rapid prototypes and end-use parts with unmatched accuracy and speed.

- Tolerances as tight as ±0.2 mm.

- ISO 9001:2015 Certified

- Production lead times starting at 24 hours.

Custom 3D Printing Services for Precision Engineering

Our tailored 3D printing solutions deliver unmatched quality and speed for prototypes and production-grade components. Leverage advanced technologies like SLA, FDM SLS, and SLM to achieve exceptional accuracy with tolerances as tight as ±0.2 mm. Trust our expertise to transform your designs into high-resolution, functional parts tailored to your exact requirements.

SLA

SLA employs UV lasers to cure liquid resin into ultra-smooth, detailed components, perfect for intricate prototypes and visual models requiring flawless surface finishes.

SLS

SLS uses precision lasers to sinter polymer powders, creating lightweight yet robust parts ideal for complex designs and end-use components in demanding environments.

SLM

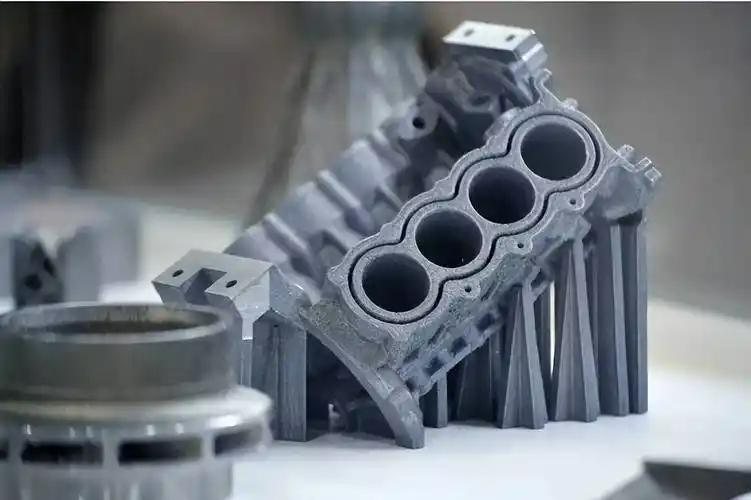

SLM melts metal powders layer by layer to craft high-density, precision metal parts optimized for aerospace, medical, and industrial applications requiring extreme durability.

FDM

FDM utilizes heated thermoplastic filaments extruded layer by layer through a precision nozzle, ideal for durable prototypes and functional parts requiring robust mechanical properties.

What is 3D Printing?

3D printing, also referred to as additive manufacturing, constructs objects layer by layer through precise material deposition or curing. Guided by digital instructions, the printer builds successive layers to form complex geometries, enabling the creation of parts from plastics, metals, or specialized materials. While diverse in technologies, all 3D printing methods share core principles of efficiency and customization.

This innovation democratizes manufacturing by offering businesses a streamlined, cost-effective solution. Compact 3D printers operate in office environments with minimal training, while low startup costs and accessible materials make small-batch production feasible. From prototypes to end-use components, 3D printing accelerates workflows and reduces traditional production barriers.

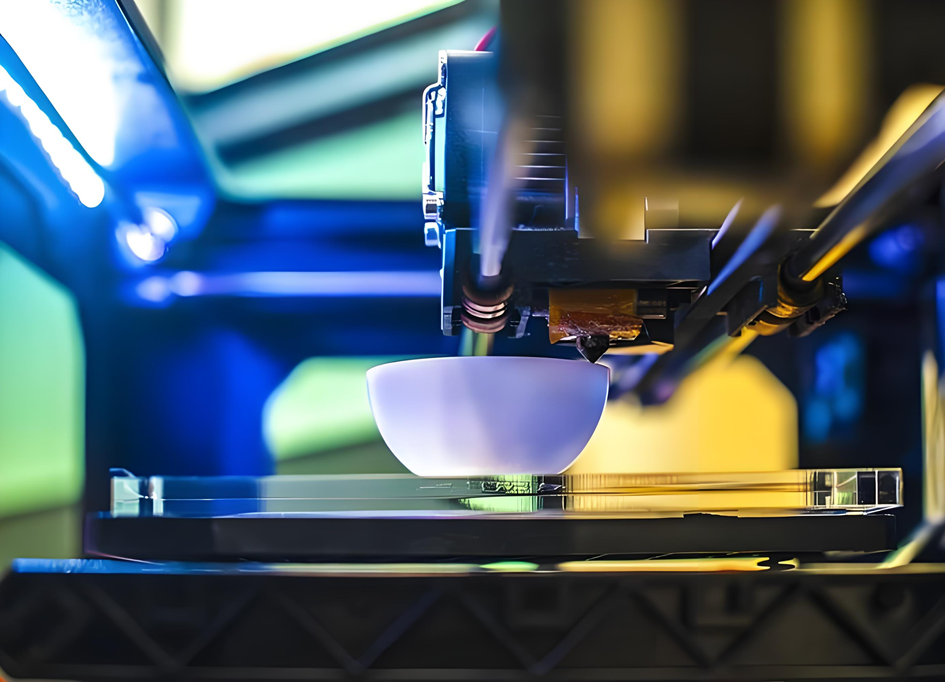

How Does SLA 3D Printing Work?

The SLA 3D printing process begins by importing a 3D model into specialized slicing software, where support structures are strategically added to ensure stability during production. The prepared STL file is then transmitted to the SLA machine, which contains a reservoir filled with liquid photosensitive resin. A build platform descends into the resin tank, and a UV laser, guided by precision optics, traces the cross-sectional contours of the model onto the resin surface. Exposure to the laser rapidly solidifies the resin in the targeted areas, forming a single cured layer. After each layer is completed, the platform lowers incrementally (typically 0.05–0.15mm), allowing fresh resin to coat the surface. This cycle repeats—curing and bonding successive layers—until the final 3D-printed object is fully constructed.

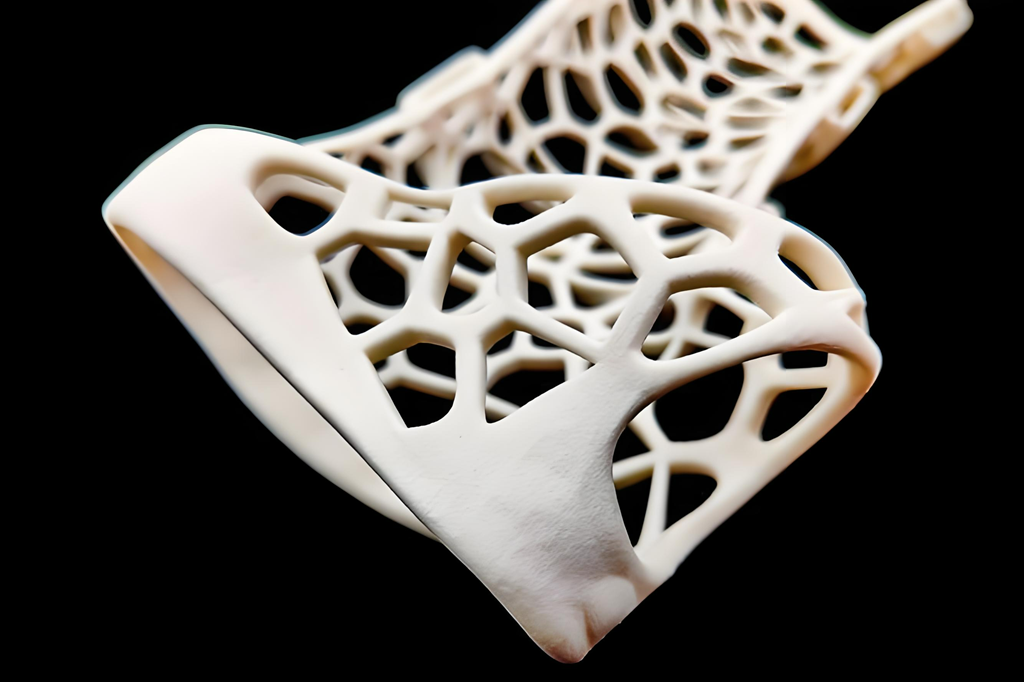

How Does SLS 3D Printing Work?

SLS 3D printing technology starts by spreading a fine layer of polymer powder across a build platform within a temperature-controlled chamber. The powder is preheated to just below its melting point, after which a high-powered laser selectively sinters the powder particles according to the digital cross-section of the model. Unsintered powder remains in place, providing natural support for overhangs and complex geometries. Once a layer is complete, the platform lowers slightly, and a recoating arm deposits a fresh, uniform layer of powder. The laser then sinters the next cross-section, fusing it to the previous layer. This layer-by-layer sintering process continues until the entire object is formed, after which the excess powder is removed to reveal the final part.

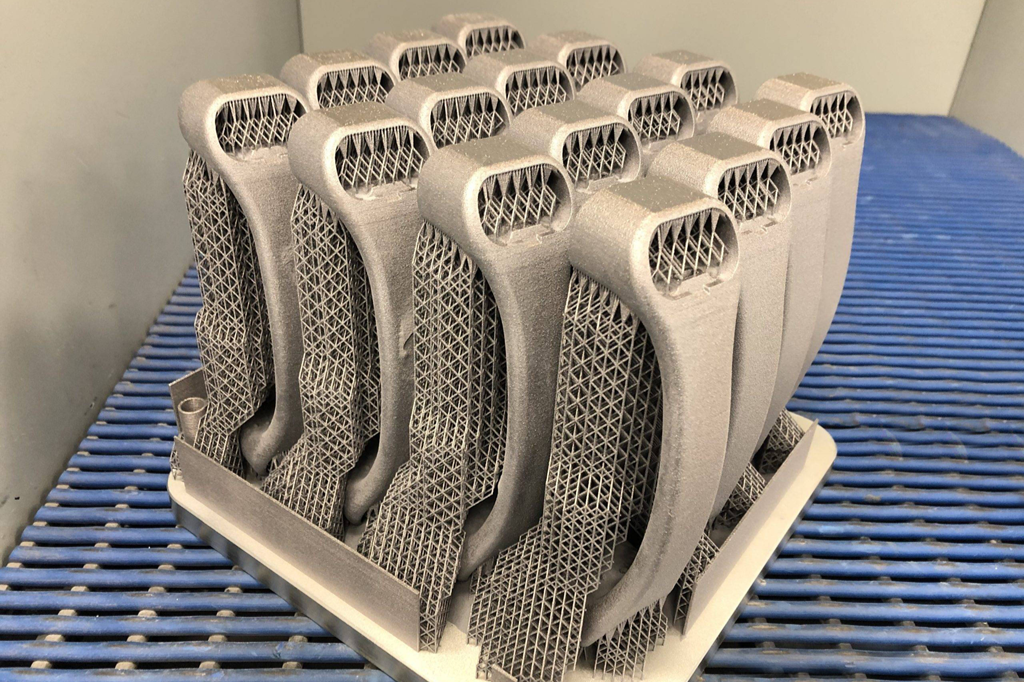

How Does SLM 3D Printing Work?

SLM 3D printing technology starts by spreading a thin layer of fine metal powder across a build platform within an inert gas-filled chamber. A high-power laser selectively scans and melts the powder particles according to the cross-sectional contours of the 3D model, fusing them into a solid layer. The surrounding unmelted powder acts as temporary support for overhangs and internal cavities. After each layer is solidified, the platform lowers slightly, and a recoater blade spreads a fresh layer of powder across the surface. The laser then melts the next cross-section, bonding it to the layer below. This cycle repeats until the entire metal component is formed, after which excess powder is removed and recycled, leaving a dense, high-strength final part.

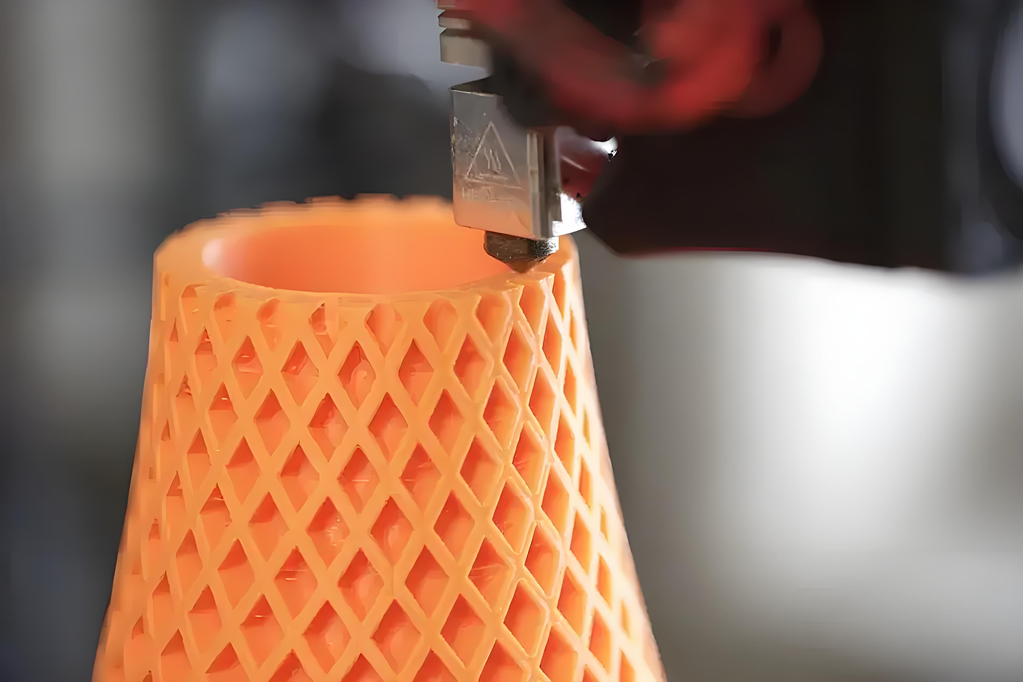

How Does FDM 3D Printing Work?

The FDM 3D printing process begins by loading a thermoplastic filament into the printer, which is fed through a heated extruder nozzle. The nozzle melts the filament and deposits it layer by layer onto a build platform, following the digital design sliced into cross-sections. As each layer is extruded, it cools and solidifies, bonding to the previous layer to form a cohesive structure. Support structures may be added for overhangs or complex geometries, which are either manually removed or dissolved post-printing. The build platform adjusts incrementally (typically 0.1–0.3mm) after each layer is completed, allowing the nozzle to continue depositing material until the final object is fully fabricated.

How to Choose the Right 3D Printing Process

Selecting the optimal 3D printing technology requires aligning project goals with process capabilities. Our additive manufacturing experts guide you through consultation and planning, evaluating design requirements, material properties, and application needs. Whether FDM, SLA, SLS, or SLM, each method demands tailored CAD file optimization for peak performance.

Submit your 3D CAD files for review, ensuring compatibility with your chosen process. Design adjustments may refine structural integrity, surface finish, or tolerance compliance. By collaborating with our team, you unlock the full potential of additive manufacturing, balancing precision, durability, and cost-efficiency for your unique project.

Advantages of SLA 3D Printing

- Ultra-high resolution for fine details and smooth surfaces.

- Ideal for intricate geometries and complex designs.

- Wide range of resin materials (flexible, rigid, or transparent).

- Minimal post-processing for aesthetic-ready prototypes.

Applications of SLA 3D Printing

- Dental Models and Surgical Guides.

- Jewelry Prototyping and Investment Casting.

- Detailed Architectural Models.

- Consumer Product Design Mockups.

Advantages of SLS 3D Printing

- No need for support structures due to powder bed fusion.

- High durability and functional performance of parts

- Compatible with engineering-grade thermoplastics.

- Efficient for small-batch production runs.

Applications of SLS 3D Printing

- Automotive Airflow Ducts and Housings.

- Industrial Robotics Components.

- Custom Prosthetics and Wearable Devices.

- Heat-Resistant Aerospace Parts.

Advantages of SLM 3D Printing

- High-density, fully dense metal components.

- Exceptional mechanical strength and heat resistance.

- Capability to produce intricate internal geometries.

- Minimal material waste due to powder recycling.

Applications of SLM 3D Printing

- Aerospace Components (e.g., turbine blades).

- Medical Implants and Orthopedic Devices.

- Automotive Lightweight Structural Parts.

- Customized Industrial Tooling and Molds.

Advantages of FDM 3D Printing

- Cost-effective and widely accessible technology.

- Durable thermoplastic materials with functional properties.

- Minimal post-processing requirements for basic prototypes.

- Compatibility with multi-material and color printing.

Applications of FDM 3D Printing

- Functional Prototypes for Mechanical Testing.

- Custom Tooling and Jigs for Manufacturing.

- Educational Models and DIY Projects.

- Low-Volume End-Use Parts in Engineering.

3D Printing Materials

Our comprehensive material portfolio includes industrial-grade plastics and metals such as ABS, PA (Nylon), Aluminum, and Stainless Steel, tailored for custom 3D printing projects across diverse sectors. For specialized material requests, select the “Other” option during quote customization. We prioritize sourcing rare or bespoke materials to meet your exact technical and performance specifications.