Precision CNC Turning Services for Custom Metal and Plastic Parts

At Samshion, we specialize in delivering precision CNC turning services tailored for OEMs, rapid prototyping, and production runs. Our advanced CNC turning capabilities ensure tight-tolerance metal and plastic parts with industry-leading speed, accuracy, and quality.

- Custom CNC Prototyping: Rapid development of functional prototypes for testing and validation.

- High & Low-Volume Production: Scalable from 1 to 10,000+ units with consistent precision.

- Tight Tolerances (±0.005 mm): Ideal for aerospace, automotive, and medical applications.

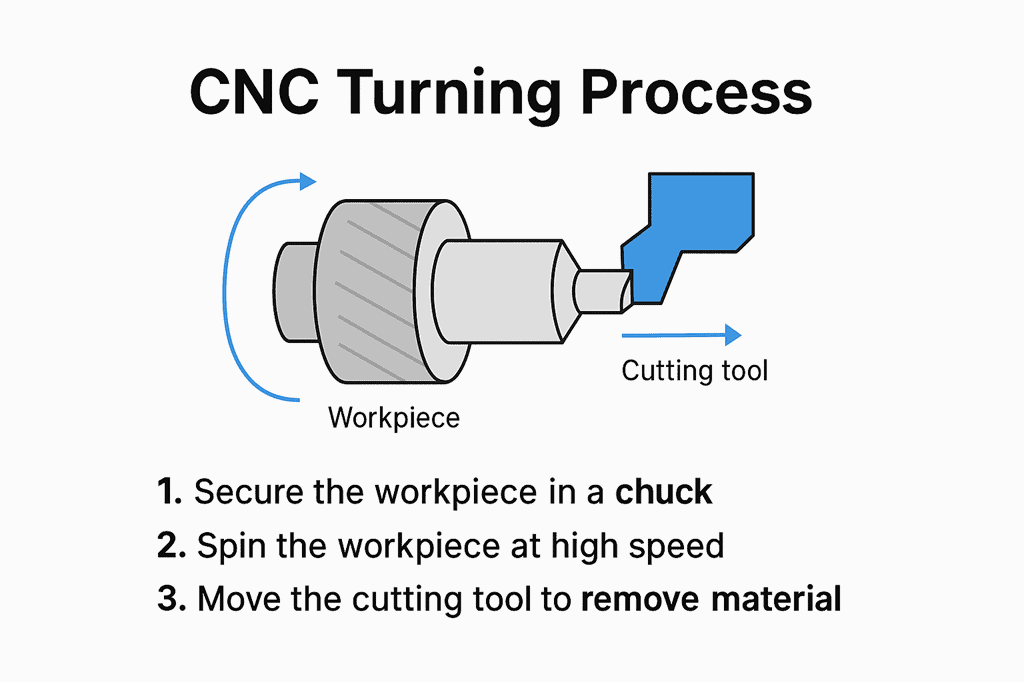

What is CNC Turning? | Precision Machining for Cylindrical Parts

CNC turning is a precision machining process where a stationary cutting tool removes material from a rotating workpiece, controlled by advanced CNC lathe machines. This method ensures outstanding accuracy, repeatability, and superior surface finishes, making it ideal for manufacturing cylindrical and tubular components such as shafts, pins, bushings, and threaded parts.

Unlike CNC milling, where the cutting tool rotates around a stationary workpiece, CNC turning spins the raw material in a chuck. This allows for efficient production of round, symmetrical geometries with tight tolerances (up to ±0.005 mm).

At Samshion, we utilize multi-axis CNC lathes with programmable turrets, enabling us to transform raw materials into complex, high-precision components for both rapid prototyping and mass production.

Why Choose Samshion for CNC Turning Services?

Samshion is your trusted partner for precision CNC turning services, delivering custom metal and plastic components with superior accuracy, consistency, and speed. Our solutions support industries like aerospace, automotive, medical, and electronics with high-quality machining at competitive lead times.

- Fast Lead Times: Rapid prototyping in 2-7 business days.

- Comprehensive Quality Inspection: Including CMM, optical measurement, and full traceability.

- Flexible Production: Scalable services from custom prototypes to volume production.

- Customer Success Focused: Long-term partnerships built on quality, service, and trust.

ISO 9001 Certified Quality

We adhere to ISO 9001:2015 certified processes, ensuring every CNC turned part meets rigorous quality standards. Perfect for industries demanding flawless precision and repeatability.

Free DFM (Design for Manufacturability) Analysis

Our engineers provide free DFM feedback to optimize your designs for cost-effective production, manufacturability, and faster turnaround.

24/7 Expert Support

A dedicated team of CNC machining experts is available 24/7 to answer technical questions, assist with design optimization, and support your project from concept to completion.

Precision Machining for Rotational Symmetry & Tight Tolerances

CNC turning is ideal for parts requiring exact concentricity, minimal runout, and micron-level precision, making it perfect for:

- Shafts, connectors, fluid system components .

- Precision threaded profiles & cylindrical parts

We guarantee tolerances up to ±0.005mm, meeting the most demanding industry standards.

Automated Efficiency & Scalable Cost Savings

Our programmable CNC lathes streamline production:

- Minimize manual intervention .

- Optimize cycle times

- Lower per-unit manufacturing costs

This enables efficient production from rapid prototypes to high-volume batches without sacrificing quality or lead time.

Broad Material Versatility for Diverse Applications

Samshion supports a wide range of materials:

- Metals: Aluminum, stainless steel, titanium, brass

- Engineering plastics: PEEK, Nylon, ABS

We cater to industries including aerospace, medical devices, automotive, electronics, ensuring material-specific performance & durability.

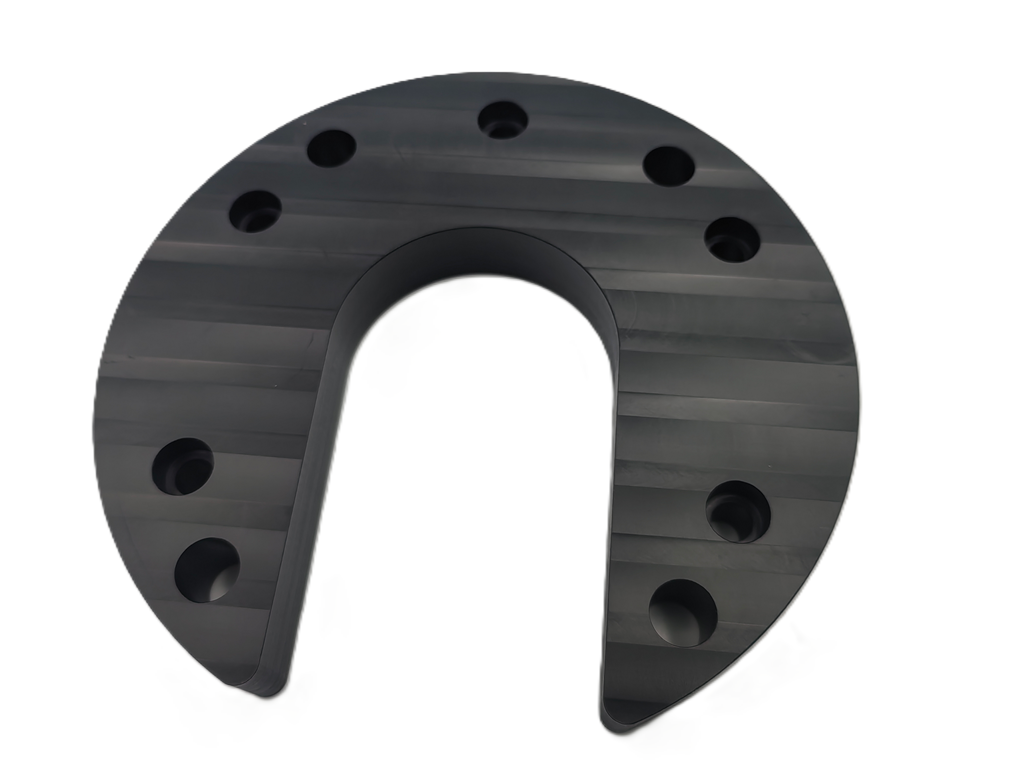

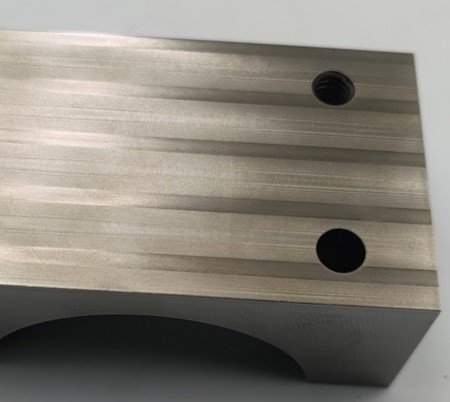

Multi-Axis Capabilities for Complex Geometries

Our advanced mill-turn CNC systems combine:

- Milling, drilling, threading in a single setup.

- Minimized part handling for improved accuracy

- Capability to create helical grooves, undercuts, and hybrid parts with tight tolerances

This allows us to tackle complex designs with precision and efficiency.

How Does CNC Turning Work?

CNC Turning is a high-precision subtractive manufacturing process where cylindrical workpieces are shaped by rotating them at high speeds while a stationary or moving cutting tool removes material to achieve the desired geometry.

Workpiece Rotation: The material (metal or plastic) is secured in a chuck and rotated at high speeds.

Tool Movement: A computer-guided turret positions cutting tools to shave off layers of the spinning workpiece.

Precision Machining: The lathe follows CAD/CAM instructions to achieve exact dimensions and surface finishes.

CNC turning is the most cost-effective solution for parts with rotational symmetry, such as spacers, connectors, or custom fasteners.

Visual Explanation Based on Image:

Step 1: Material Clamping & Rotation

The raw material, either metal (aluminum, brass, steel) or plastic (nylon, PEEK), is firmly secured in the chuck of a CNC lathe (black and silver rods in the image).

The chuck rotates the workpiece at high RPM to ensure concentricity and stability.

Step 2: Precision Tool Engagement

A turret-mounted cutting tool engages the surface of the spinning workpiece.

Tools perform facing, turning, boring, threading, and grooving operations.

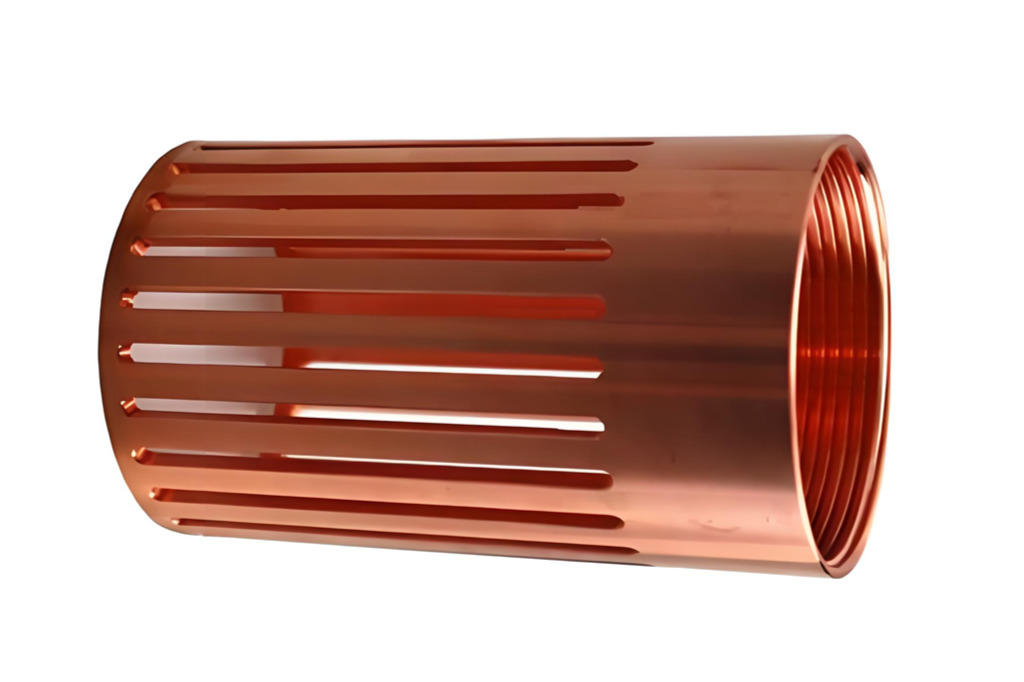

The gold-colored hollow cylinder in the image showcases through-holes and grooves created via CNC turning + milling.

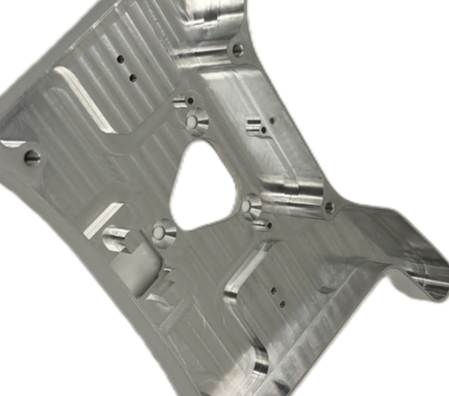

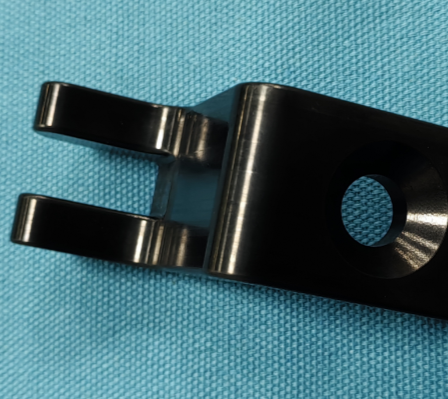

Step 3: Layer-by-Layer Material Removal

As the tool moves along X (radial) and Z (axial) axes, it precisely cuts away material to form:

External cylindrical profiles (as shown in black and silver turned shafts)

Internal bores and threads (visible in the black flanged components)

Undercuts and special features (like the cross-drilled holes in the middle gold part)

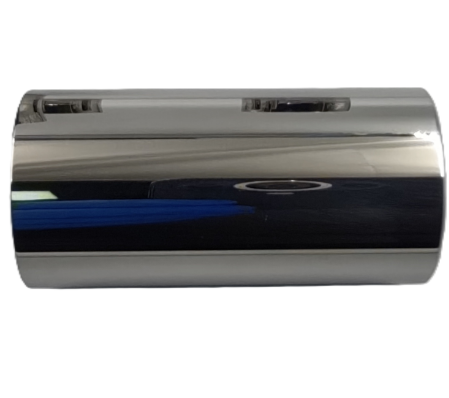

Step 4: Achieving Final Geometry & Finish

CNC turning ensures micron-level tolerances and smooth surface finishes.

The black anodized and silver polished parts in the image demonstrate both functional machining and surface finishing steps.

CNC Turning Materials — Precision Across Metals & Plastics

At Samshion, we offer extensive material options for CNC turning to meet diverse industry requirements with precision and consistency. Whether you need robust metal components or lightweight plastic parts, we ensure material-specific machining excellence.

Metals for High-Strength, Durable Components

We machine a wide variety of metals, chosen for their mechanical strength, corrosion resistance, and application versatility: Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper, Magnesium Alloy, Titanium Alloy, Zinc Alloy.etc.

Plastics for Lightweight, Functional Parts

For applications demanding light weight, chemical resistance, or electrical insulation, we offer: ABS, PC, ABS+PC, PMMA(Acrylic), PA(Nylon), PA+GF30, POM(Acetal / Delrin), PP, PVC, HDPE, PPS, PEEK, PEI(Ultem), Teflon, Bakelite Resin, Epoxy Tooling Board.etc.

Description:

Aluminum alloys are engineered metallic materials composed primarily of aluminum combined with elements such as copper, magnesium, silicon, or zinc. Renowned for their exceptional strength-to-weight ratio, corrosion resistance, and versatility, aluminum alloys are widely used across industries ranging from aerospace to consumer electronics.

Alloys:

6061-T6, 7075-T6, 7050, 2024, 2A12,6082,5083,5052, 6063, MIC6.etc.

Finishing Options:

Alodine, Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing.

Description:

Stainless steel is a corrosion-resistant iron-based alloy containing a minimum of 10.5% chromium, combined with elements like nickel, molybdenum, and carbon. Renowned for its durability, aesthetic versatility, and hygienic properties, stainless steel is a cornerstone material in industries ranging from medical devices to architectural design.

Alloys:

303, 304L, 316L, 410, 416, 440C, 17-4PH, Nitronic 60.etc.

Finishing Options:

Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Black Oxide, Zinc Plating, Vibratory Tumbling.

Description:

Copper, a ductile and malleable metal with exceptional electrical and thermal conductivity, is a cornerstone of modern technology and industrial applications. Known for its natural reddish-brown hue, corrosion resistance, and recyclability, copper and its alloys are indispensable in sectors ranging from electronics to renewable energy.

Alloys:

C1100,C1011.etc.

Finishing Options:

Media Blasting, Nickel Plating, Passivation, Tumble Polishing, Vibratory Tumbling.etc.

Description:

Brass alloys are versatile metallic materials primarily composed of copper and zinc, often enhanced with elements like lead, tin, or aluminum. Known for their excellent machinability, corrosion resistance, and aesthetic appeal, brass alloys are widely utilized in industries such as plumbing, musical instruments, decorative hardware, and electrical components.

Alloys:

C260, C360, C464, C485, C280, C220, C230, C510, C544, C675.

Finishing Options:

Polishing, Electroplating (Nickel, Chrome), Clear Lacquering, Antiquing, Powder Coating, Passivation, Sandblasting, Brushed Finish, Hot-Dip Galvanizing, Laser Etching.

Description:

Steel alloys are engineered metallic materials primarily composed of iron and carbon, often enhanced with elements like chromium, nickel, or molybdenum. Renowned for their exceptional strength, durability, and resistance to wear and corrosion, steel alloys are extensively used in industries such as construction, automotive manufacturing, industrial machinery, and tooling.

Alloys:

1045 Carbon Steel, A36 Mild Steel, 4140 Chromoly Steel, 4340 High-Strength Steel, D2 Tool Steel, A2 Tool Steel, 52100 Bearing Steel, 8620 Case-Hardening Steel.

Finishing Options:

Heat Treatment (Quenching, Tempering), Galvanizing, Powder Coating, Electroplating (Nickel, Chrome), Media Blasting, Passivation, Polishing, Black Oxide Coating, Anodizing, Laser Engraving.

Description:

Titanium alloys are advanced metallic materials primarily composed of titanium blended with elements like aluminum, vanadium, or nickel. Renowned for their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, titanium alloys are critical in high-performance industries such as aerospace, medical implants, marine engineering, and chemical processing.

Alloys:

Ti-6Al-4V (Grade 5), Ti-3Al-2.5V (Grade 9)

Finishing Options:

Anodizing (Type II, III), Media Blasting, Electropolishing, Passivation, Thermal Oxidation, PVD Coating, Laser Marking, Chemical Etching, Powder Coating, Grinding/Polishing.

Description:

Magnesium alloys are lightweight metallic materials primarily composed of magnesium combined with elements such as aluminum, zinc, or manganese. Renowned for their exceptional strength-to-weight ratio, vibration damping properties, and machinability, magnesium alloys are widely utilized in high-performance industries including aerospace, automotive lightweighting, consumer electronics, and biomedical devices.

Alloys:

AZ31B, AZ91D,

Finishing Options:

Anodizing (Type I, II), Chemical Conversion Coating (Chromate, Phosphate), Electroplating (Nickel, Copper), Powder Coating, Laser Etching, Passivation, Polishing, PVD Coating, Epoxy Sealing, Thermal Spraying.

Description:

ABS (Acrylonitrile Butadiene Styrene) is a versatile thermoplastic polymer celebrated for its excellent impact resistance, thermal stability, and ease of processing. Combining rigidity, surface gloss, and electrical insulation properties, ABS is extensively utilized in automotive parts, consumer electronics, household appliances, toys, and industrial piping systems.

Colors:

Opaque beige, Black.

Finishing Options:

As machined, Media blasting, Polishing, Painting, Texture coating, Clear lacquering, Electroplating

Description:

POM (Polyoxymethylene) is a high-performance engineering thermoplastic renowned for its exceptional mechanical strength, low friction coefficient, superior dimensional stability, and resistance to chemicals. With outstanding wear resistance and anti-creep properties, POM is widely used in precision mechanical components, gears, bearings, electronic connectors, medical devices, and automotive systems.

Colors:

White, Black.

Finishing Options:

As machined, Media blasting, Polishing,

Description:

Nylon is thermoplastic with high strength, wear resistance, excellent sound/vibration dampening, and low friction coefficient. It is commonly used in engineering and manufacturing processes. Common applications include gears, bearings, and bushings. Two of the most notable use cases for Nylon are in medical devices and electronics insulation, notably screws and spacers for panel mounted circuit boards.

Colors:

Opaque beige, Black.

Finishing Options:

As machined, Media blasting, Polishing,

Description:

PEEK, (polyether ether ketone) is a thermoplastic widely used in industries such as aerospace, automotive, and electronics. PEEK has high strength, stiffness, toughness, chemical, biocompatibility, and thermal resistance. Due to its , PEEK is also suitable for use in harsh environments where other materials may fail. Common applications include aircraft structures, electronic components that require high temperature resistance, and medical and dental components (including implantables).

Colors:

Opaque beige

Finishing Options:

As machined, Media blasting, Polishing,

Description:

PE is flexible, chemical-resistant, and impact-resistant.

Lightweight and cost-effective, this material is ideal for packaging, containers, and piping systems where durability and adaptability are essential.

Color:

Natural White,Black,

Finishing Options:

As machined, Sand blasting, Tumbling,

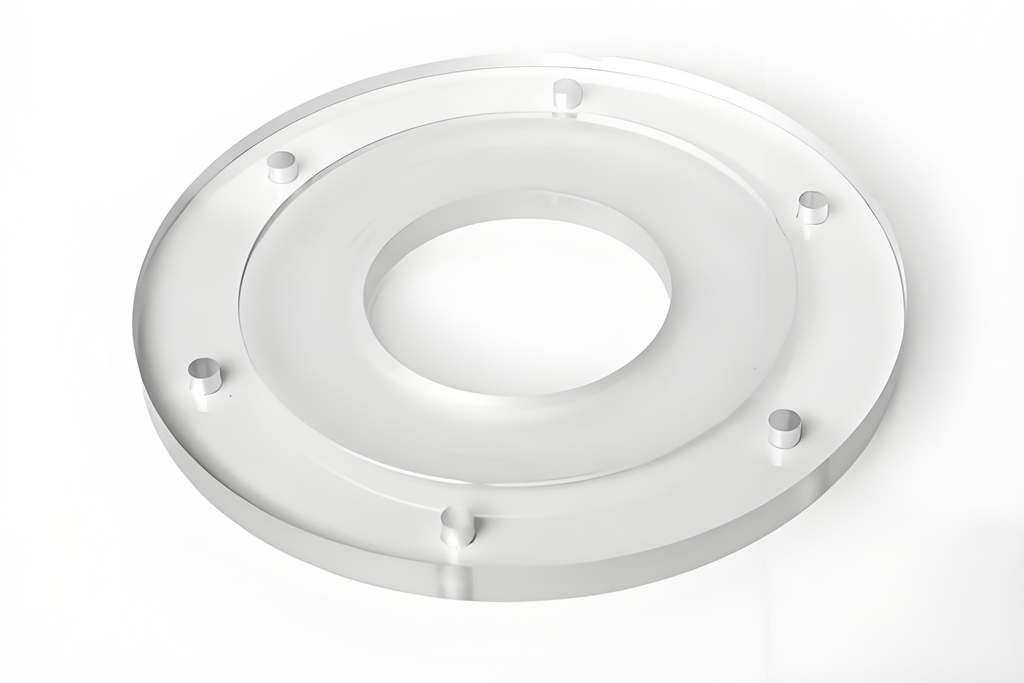

Description:

Polycarbonate (PC) is renowned for its exceptional clarity, high impact resistance, and thermal stability. Widely used in optical lenses, automotive components, and protective equipment, PC maintains structural integrity under stress while offering lightweight versatility.

Color:

Transparent,Black,

Finishing Options:

As machined, Media Blasting, Polishing, Anti-Scratch Coating, Painting, Textured Finish, Laser Etching

Description:

HIPS is lightweight, impact-resistant, and easy to machine.

Ideal for prototyping and consumer products, this material balances durability and cost-effectiveness while offering excellent surface finish for aesthetic applications.

Color:

Natural White,Black,

Finishing Options:

As machined, Media blasting, Polishing, Painting, Texture coating, Clear lacquering, Electroplating

Standard Tolerances for Linear Dimensions (ISO 2768)

Values in millimeters

| Basic Size Range | Fine (±) | Medium (±) | Coarse (±) | Very Coarse (±) |

|---|---|---|---|---|

| 0.5 ≤ 3 | 0.05 | 0.1 | 0.2 | – |

| >3 ≤ 6 | 0.05 | 0.1 | 0.3 | 0.5 |

| >6 ≤ 30 | 0.1 | 0.2 | 0.5 | 1 |

| >30 ≤ 120 | 0.15 | 0.3 | 0.8 | 1.5 |

| >120 ≤ 400 | 0.2 | 0.5 | 1.2 | 2.5 |

| >400 ≤ 1000 | 0.3 | 0.8 | 2 | 4 |

| >1000 ≤ 2000 | 0.5 | 1.2 | 3 | 6 |

| >2000 ≤ 4000 | – | 2 | 4 | 8 |

Samshion’s CNC Turning Tolerance Standards

At Samshion, we adhere to ISO 2768 standards for precision:

- Plastic Parts: Medium tolerance (ISO 2768-M) for cost-effective production.

- Metal Parts: Fine tolerance (ISO 2768-F) for high-accuracy applications.

Typical Tolerance Ranges:

- Standard: ±0.005” (±0.127 mm)

- High Precision: ±0.002” (±0.05 mm)

For mission-critical components requiring tighter tolerances (e.g., ±0.001” or ±0.025 mm), submit a 2D engineering drawing with detailed specifications. Our engineering team will collaborate with you to optimize manufacturability and ensure flawless execution.

Part lengths of up to 40″ are available on our platform process dependent. Please inquire about anything larger. Tolerances listed here are minimums for an ideal case. Looser tolerances may be required depending on process, material choice, or part geometry.

Professional Surface Treatments for CNC Turned Components

CNC Turning Parts Surface Finishes

At Samshion, we offer a comprehensive range of premium surface finishes for CNC turned parts to meet diverse functional and aesthetic requirements. From corrosion protection to visual enhancement, our finishing solutions—such as anodizing, sandblasting, and polishing—ensure your components are both high-performing and visually appealing.

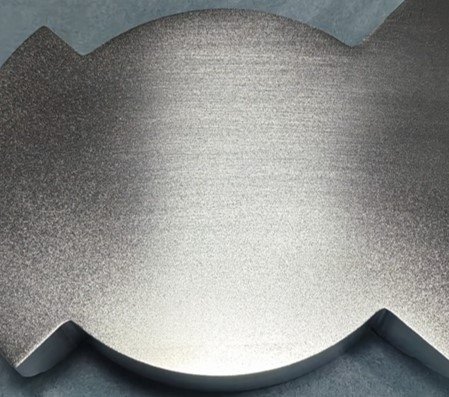

As Machined

The as-machined finish delivers parts directly from CNC machining, retaining minor tool marks for a cost-effective solution. Ideal for functional prototypes and non-critical components requiring no post-processing.

Anodizing

Anodizing enhances corrosion resistance, wear resistance, and aesthetics for aluminum parts. Custom colors and glossy finishes available.

Polishing

Achieve a mirror-like finish with polishing, reducing surface roughness to Ra 0.2 µm. Perfect for luxury products and optical components.

Sand Blasting

Sand blasting creates a uniform matte texture, hiding imperfections and improving paint adhesion. Uses pressurized media for consistent results.

Tumbling

Tumbling smooths edges and surfaces via friction in a rotating barrel, offering a slightly textured, uniform finish for small parts.

Electropolishing

Electropolishing chemically removes surface layers to enhance smoothness, brightness, and corrosion resistance. Ideal for stainless steel and medical devices.

Alodine

Alodine coating provides corrosion protection and paint adhesion for aluminum, with a conductive yellow film.

Heat Treatment

Heat treatment enhances metal properties like hardness, strength, or ductility in a controlled vacuum environment.

Brushed Finish

A brushed finish creates a unidirectional satin texture, masking scratches and adding aesthetic appeal.

Powder Coating

Powder coating applies a thick, wear-resistant polymer layer with vibrant color options and UV resistance.

Nickel Electroplating

Electroplating deposits a thin nickel layer for enhanced wear resistance, conductivity, and corrosion protection.

Black Oxide Coating

Black oxide forms a magnetite layer on ferrous metals, reducing glare and improving corrosion resistance.

Uncompromising Quality Assurance

At the heart of Samshion’s operations lies an uncompromising quality philosophy. Advanced spectroscopy verifies every material batch, while 3D scanning systems validate dimensional compliance to micrometer-level precision. Monthly process audits and a 99.2% first-article acceptance rate reflect our dedication to continuous improvement. This disciplined approach has fostered long-term partnerships, with 40% of clients returning for repeat projects over five consecutive years—a testament to our ability to balance speed, precision, and reliability.

Advanced Inspection Technology

We deploy cutting-edge equipment to guarantee unmatched precision:

- CMM & 3D Scanners: For micron-level dimensional accuracy.

- XRF Analyzers: Verify material composition and RoHS compliance.

- Optical Comparators & Micrometers: Ensure surface finish and critical tolerances.

- Automated Gauging Systems: Real-time monitoring for consistency.

End-to-End Quality Control

Our ISO 9001:2015 certified team enforces rigorous checks at every stage:

- Pre-Production: DFM analysis and material certification.

- In-Process: Statistical process control (SPC) and on-site inspections.

- Final Audit: Functional testing, visual inspections, and performance validation.

- Documentation: Detailed reports including FAIs, PPAP, and compliance certificates.

Trusted by Global Industries

With 20+ years of expertise, Samshion delivers:

- Zero-Defect Guarantee: Rooted in Six Sigma methodologies.

- Fast Turnarounds: Prototypes in 3 days, production batches in 7 days.

- Full Traceability: Material certs, inspection logs, and compliance documentation.

Optimize Your Designs for High-Precision Turning

CNC Turning Design Guidelines

At Samshion, we help you streamline part designs for CNC turning to maximize manufacturability, reduce costs, and ensure flawless production. By following our CNC turning-specific guidelines, you can avoid unnecessary revisions, accelerate production, and guarantee high-quality results for rotationally symmetric parts.

Key CNC Turning Design Considerations:

Turned Diameters & Length Ratios

Maximum L/D Ratio: Maintain length-to-diameter ratios ≤ 4:1 for unsupported shafts to avoid deflection.

Supported Shafts: Higher L/D ratios possible with tailstock or steady rest support.

Best Practice: Design with rigidity in mind for accurate concentricity.

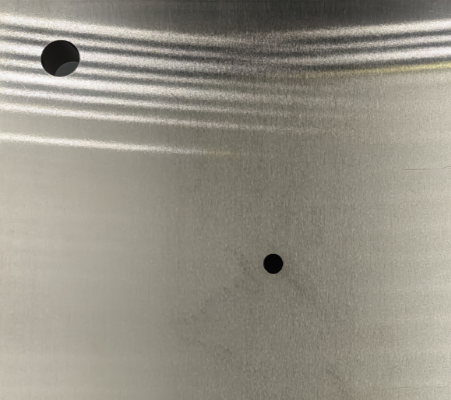

Internal Bores & Holes

Minimum Bore Diameter: ≥ 2 mm, depending on depth.

Maximum Bore Depth: ≤ 4× bore diameter for tool reach and stability.

Tip: Avoid long, narrow bores without support to prevent chatter and tolerance issues.

Threads & Grooves

External Threads: Minimum diameter ≥ 3 mm for reliable cutting.

Internal Threads: Depth ≤ 2× thread diameter recommended.

Undercut Grooves: Essential for clean thread runouts and assembly clearance.

Custom Solutions: Metric, UNC, UNF, and custom thread profiles available.

Chamfers & Fillets

Chamfers: Preferable over sharp edges for easy assembly and improved safety.

Fillets (Radii): Internal corners naturally have a fillet due to tool geometry; specify radii ≥ tool nose radius (typically ≥ 0.5 mm).

Surface Finishes for Turned Parts

Standard Ra 3.2–1.6 µm for functional parts.

Ra 0.8–0.2 µm achievable with fine turning or polishing for aesthetic surfaces.

Surface Treatments: Anodizing, polishing, bead blasting available for enhanced performance and appearance.

Why Follow These Guidelines?

- Reduce Costs: Prevent design flaws and tooling conflicts early.

- Faster Lead Times: Efficient designs enable 3–5 day production cycles.

- Precision Guaranteed: Achieve tight tolerances down to ±0.02 mm with ISO 9001-certified turning processes.

CNC Turning Services – Frequently Asked Questions (FAQ)

1. What is CNC turning and how does it differ from CNC milling?

CNC turning involves rotating the workpiece while a stationary cutting tool shapes it, making it ideal for cylindrical or symmetrical parts like shafts, bushings, and rings. In contrast, CNC milling rotates the cutting tool while the workpiece remains stationary, better suited for prismatic and complex geometries.

2. What materials can be processed with CNC turning?

At Samshion, we work with a wide range of materials, including:

Metals: Aluminum, Stainless Steel, Brass, Copper, Titanium, Alloy Steel.

Plastics: POM, ABS, Nylon, PTFE, PEI (Ultem).

Exotic materials: Inconel, Hastelloy, etc.

Material selection depends on your part’s functional and cosmetic requirements.

3. What is the typical tolerance achievable with CNC turning?

Standard tolerances are ±0.05 mm, while high-precision CNC turning can achieve ±0.02 mm upon request. Tolerances depend on material, geometry, and production volume.

4. What surface finishes are available for turned parts?

We offer various surface treatments to meet functional and aesthetic needs:

As-machined (Ra 3.2–1.6 µm)

Polishing (down to Ra 0.2 µm)

Anodizing (Type II & Type III)

Bead blasting

Electroplating & powder coating

5. What are the size limitations for CNC turned parts?

Maximum turning diameter: 500 mm

Maximum part length: 1000 mm

For micro components, we can machine diameters as small as 2 mm.

6. Can Samshion produce prototypes and low-volume CNC turning parts?

Absolutely. We specialize in both prototyping and small to medium batch production, providing flexible and cost-effective solutions with fast turnaround times (as fast as 3–5 working days).

7. How can I get a quote for CNC turning services?

Simply send us your 3D CAD files (STEP, IGES) and 2D drawings (PDF) along with material, quantity, and finish requirements. Our team will provide a detailed quote within 24 hours.

8. What is the typical lead time for CNC turning orders?

Rapid Prototypes: 3–5 working days

Batch Production: 7–15 working days, depending on complexity and volume

Expedited services are available for urgent projects.

9. Does Samshion provide quality inspection reports?

Yes, we offer comprehensive quality control, including:

First Article Inspection (FAI)

Dimensional inspection reports

Material certificates (COC, RoHS compliance)

ISO 9001-certified processes