Precision Plastic Injection Molding - From Prototype to 1M+ Parts

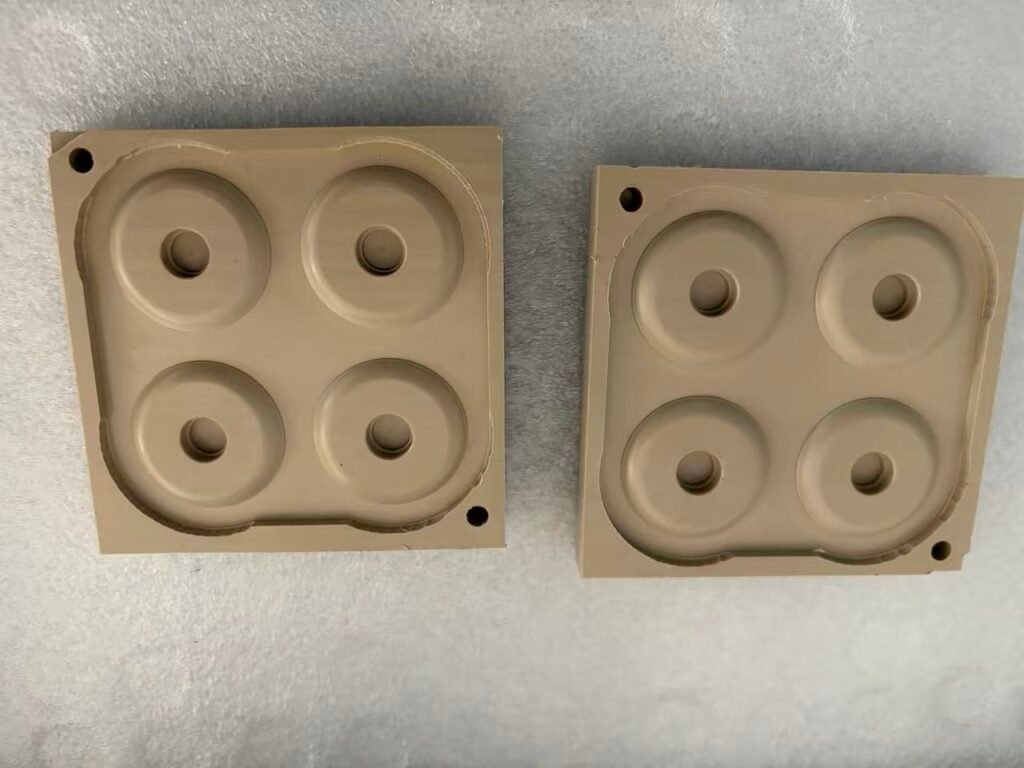

Aluminum & Steel Molds

50+ Engineering-Grade Materials

15-Day Production Launch

What Is Plastic Injection Molding?

Injection molding is a molding method that uses pressure to fill in the mold with plastic liquid that is heated and melted, and then cools and solidifies inside the mold.The mold can be single cavity or multiple cavities with short cycle time.It can form the plastic products with complex shape and precise dimension.It has high production efficiency and is easy to achieve automatic operation.Injection molding is suitable for mass production and complex shape products and other molding processing fields.

Samshion Rapid is a high quality rapid tooling and injection molding service supplier that can provide complete manufacturing solutions and no MOQ request.Our mold workshop and injection molding workshop are managed by experienced engineers.We can also provide you with a high level of professional technical support by our professional technical team so as to ensure that your parts are correctly completed at the first time.No matter for the sake of shortening the lauching time,saving the tooling cost,part price and extending the tooling life or for all these sakes,we can cooperate with you to meet your demands.Just upload your cad to get the quote and DFM freely.

Plastic Injection Molding Process

Preparation before injection molding:

-Raw material preparation: including plastic particle , plastic drying, pigment mixing.

-Tooling preparation: set up the tooling on the machine and do the inspection and maintainence to ensure the tooling quality and performance so as to meet the production requirements.

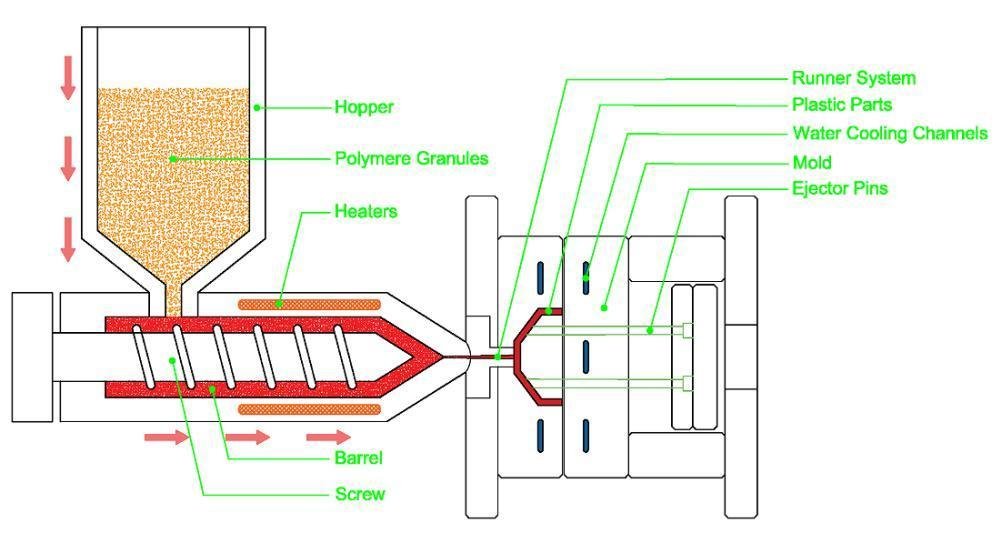

-The dry particles are poured into the hopper of the injection molding machine,when the particles are fed into the barrel,they are heated and melted at the same time.

The injection molding process is divided into six cycle steps:

mold closing, injection, pressure holding, cooling, mold opening and ejection. These six stages directly determine the molding quality of the product, and these six stages are a complete continuous process.

Step 1 – Mold closing:

Supply the mold with enough clamping force to resist the cavity pressure caused by melting plastic entering the cavity.It can prevent the mold from opening, resulting in bad products.

Step 2 – Injection:

The melted plastic is injected into the cavity . The injection molding machine controls the plastic flow speed and pressure in the injection process by controlling the screw rod speed and the injection pressure.

Step 3 – Holding Pressure:

The function of the pressure holding stage is to continuously apply pressure to the mold cavity, compacts the melted plastic and increases the plastic density to compensate for the plastic’s shrinkage, so as to ensure the part’s dimensional accuracy and consistency.

Step 4 – Cooling:

After the plastic is injected into the cavity,the cooling system in the mold reduces the mold temperature by cooling water or cooling oil, which helps the plastic solidify quickly.

Step 5 – Mold opening:

After the plastic is solidified,the injection molding machine will open the mold by hydraulic or mechanical system.

Step 6 – Ejection :

After the mold is opened, the ejector system is activated and the parts are ejected.

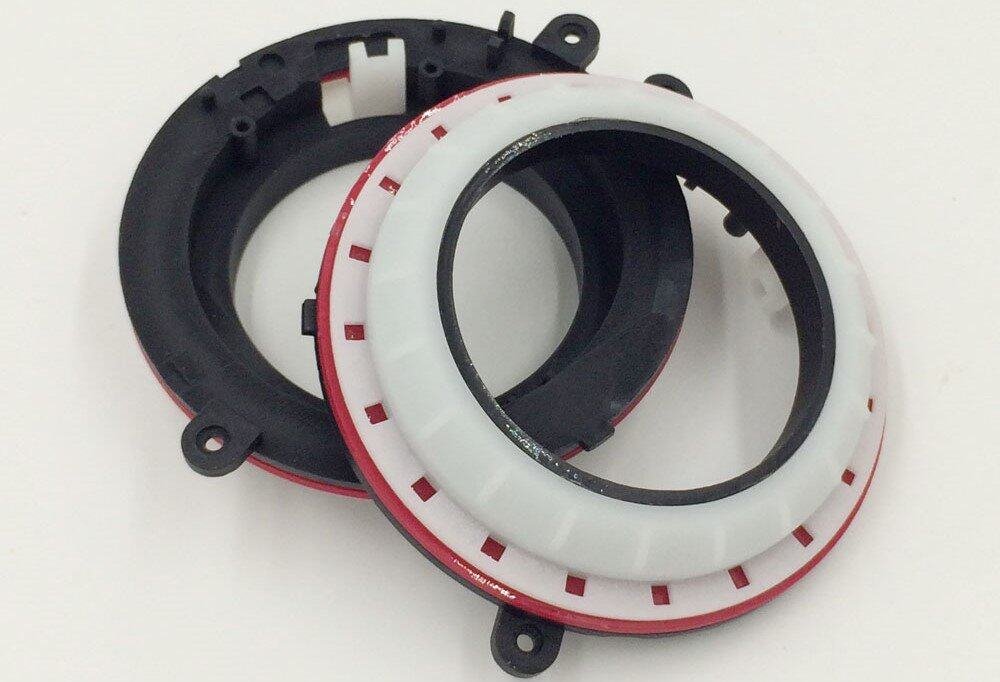

What’s overmolding?

Overmolding is a kind of injection molding process, it is formed with a variety of materials stacked together to get a composite product.It is a composite part formed by placing a prefabricated part into another mold cavity for injection molding again, and stacking two kinds of materials together.

The advantages of overmolding is that it can achieve diversity of materials, diversity of colors and flexibility of design.It can also provide additional protection, appearance improvement or additional functions for the product.It is widely used in electronic products, tool handles and household goods and other fields, with good appearance and touch.

What’s insert overmolding?

Insert overmolding is an injection molding process that metal inserts or other material parts are over molded into plastic products.It is molded by placing the metal insert into the mold cavity. This process is to inject the melted plastic into the mold cavity, so that the insert and the plastic are combined into a whole part.

The advantage of overmolding is that it can realize to get complex structural parts and functional parts with strong mechanical properties, functionality and good appearance.It is widely used in automotive, medical equipment, industrial machinery and electronic equipment and other fields.

Why choose us?

Injection molding is usually suitable for small batch or high volume production with more materials choices and color flexibility.Injection molding has a wide range of applications and is suitable for various shapes and sizes which can produce a variety of plastic products.

All-round services

We not only provide you the rapid tooling service,but also provide prototyping,CNC and traditional mold manufacturing and injection molding as well as the complete product manufacturing solutions

Competitive price

We are the source factory, every manufacturing process is completed in our own factory, both manufacturing costs and production time are within our control.

DFM feedback

Upload your 3D CAD data for a quote, do a full Design for Manufacturing (DFM) analysis for free, and you’ll get better feedback while saving more money and time.

Strict quality control

Certified to ISO 9001:2015, our laboratory has deployed powerful measuring instruments and an excellent team of quality engineers, combined with a strict quality control process to ensure that every piece is of high quality before it can be shipped.

No MOQ

You can order according to your inventory, no minimum order requirement.

Rapid quotation

A rapid and accurate and transparent quote can be acheived within 24 hours.

The applications of plastic injection molding

Plastic injection molding is a common processing method and widely used in various fields. injection molding technology provide important support for product manufacturing in different fields with the advantages of its molding speed, high production efficiency, high product precision.

Electronics Industry

Injection molding technology is the most widely used in the electronics industry, which can meet the requirements of complex geometry, miniaturization and precision.It can also produce products with good appearance and texture as well as achieve high output production, low cost so as to meet the needs of the electronic product market.

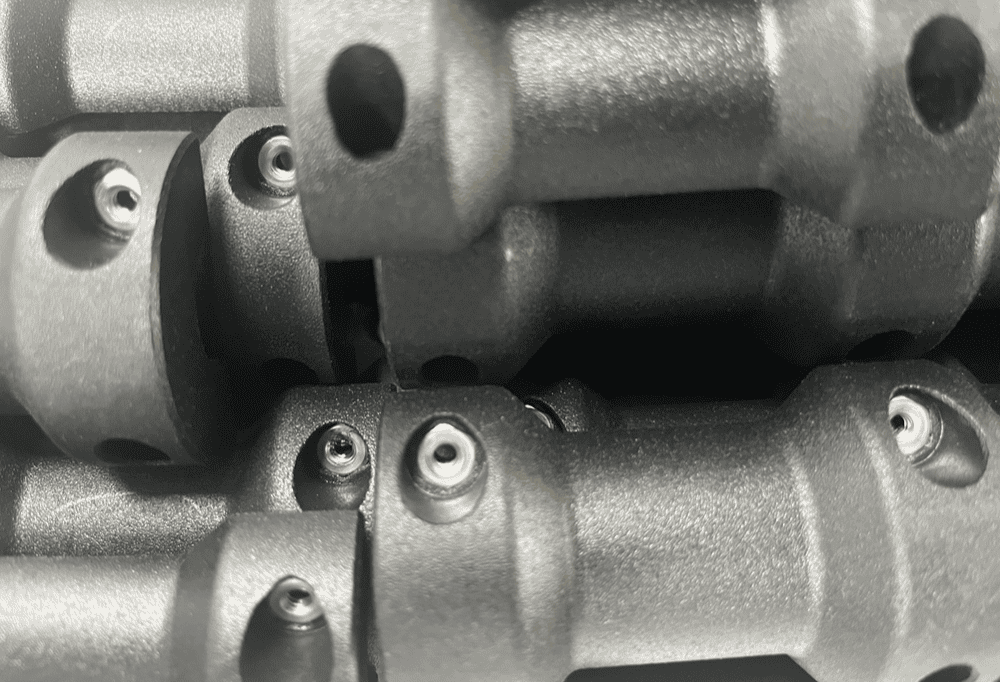

Automotive industry

The automotive industry is also one of the application areas of injection molding technology.It can better realize parts with complex shape and can be well controlled dimensional accuracy and good appearance requirements.Compared to traditional metal processing, the injection molding process is more efficient and less costly.

Medical industry

There are high safety and sanitary requirements for medical devices.Injection molding is widely used in medical industry.The manufacturing process and quality control must strictly comply with relevant standards and regulations, and take appropriate control measures to ensure the quality and reliability of medical devices.

Household appliance industry

Injection molding also has important applications in the home appliance industry which can achieve complex shape and complex structure of home appliance parts.It has good durability and appearance, whether it is the exterior shell parts or internal functional structure parts, injection molding technology can meet the requirements.

Material of plastic injection molding

Injection molding is the most common method of producing plastic parts, and there are many kinds of plastic materials used for injection molding.When selecting injection molding materials, it is necessary to consider the physical properties, chemical properties, environmental protection and production costs and other factors.Different materials have different properties and need to be selected according to actual needs.

The ten most commonly used injection molding materials:

ABS ( Acrylonitrile Butadiene Styrene)

PMMA( Acrylic)

PC (Polycarbonate)

PA( Nylon)

POM( Acetal/Delrin)

PP (Polypropylene)

PE (Polyethylene)

PS (Polystyrene)

TPE(Thermoplastic Elastomer)

TPU(Thermoplastic Polyurethane)

FAQ for injection molding

Injection molding is one of the most commonly used manufacturing process for plastic products which is achieved by injection molding machine and mold.The injection molding machine melts the plastic into liquid plastic by heating it and then uses high pressure to shoot into the mold cavity,and then obtains the part after cooling.

Part structure complexity, appearance requirements, dimensional tolerance requirements, product material selection, production quantity, mold cavity quantity, mold cost and injection molding machine tonnage size, these factors will directly affect the cost of injection molding.

A rapid and accurate and transparent quote can be acheived within 24 hours after you upload the data.

It depends on the complexity of product design, size and mold structure complexity. For simple structure products,it’s usually finished from 10 days to 4 weeks.

Mold cost is also a relatively large investment in the early stage of the product.Reducing mold cost needs to optimize product design, mold design, mold manufacturing, monitoring DFM analysis and other aspects.Through these methods we can effectively reduce mold costs, improve production efficiency and quality.

We don’t have to MOQ for the injection molding.You can order per your actual request which can better suport your development.