Customized Laser Cutting Solutions

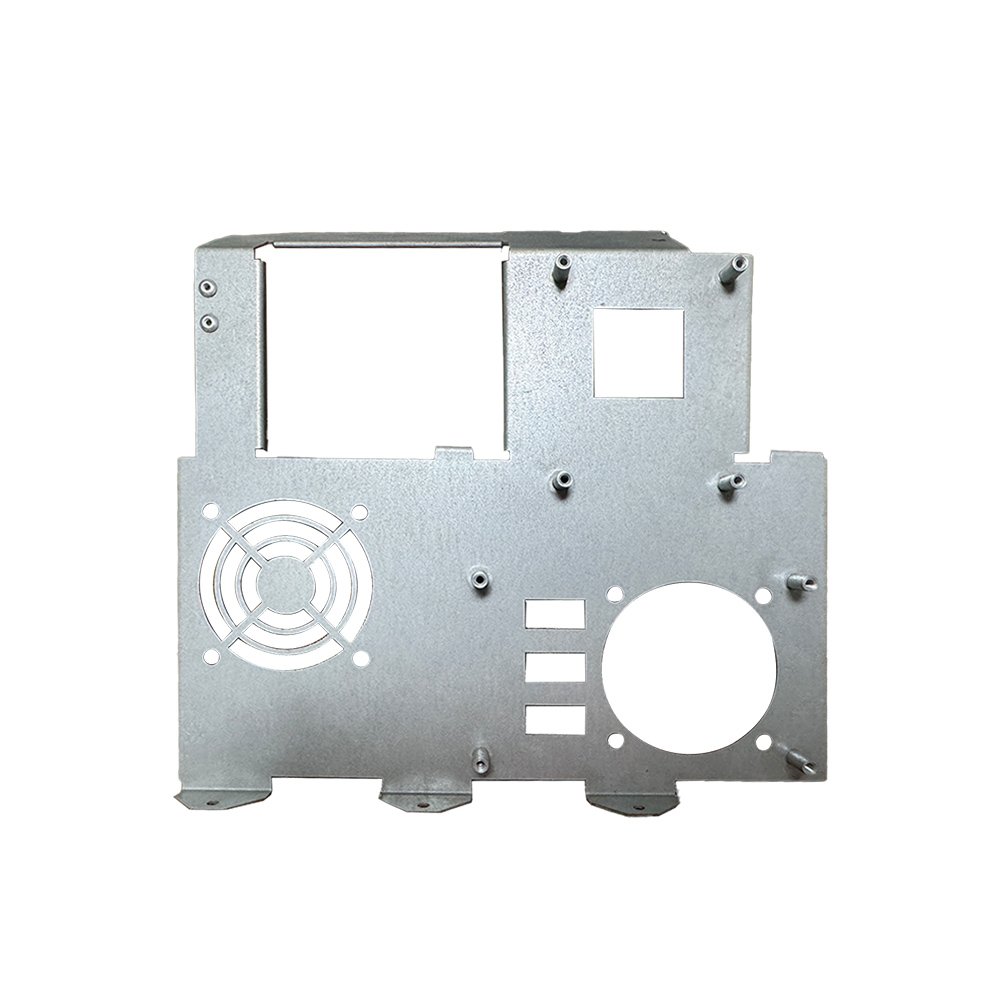

Samshion deliver high-precision laser cutting solutions for aluminum, steel, and industrial polymers, seamlessy bridging the gap from rapid prototyping to mass production.

- 24-hour DFM feedback

- Rapid Prototyping & Functional Testing

- Smooth Surface, Burr-Free Edges

Why Choose Samshion Rapid for Laser Cutting Services?

Samshion don’t just cut metal; we deliver perfection. Our high-power fiber laser systems are calibrated for burr-free results and exceptionally smooth surfaces. By eliminating the need for secondary manual deburring, ensuring your parts are safe to handle and ready for immediate assembly or surface treatment.

Precision Tolerances: Up to ±0.05mm for consistent accuracy across thousands of parts.

Zero Post-Processing: Clean cuts that save you time and labor costs.

Rapid Prototyping: Get functional test parts in your hands in 24 hours.

We are willing to transform your designs into high-performance parts. Our engineering team is standing by to provide a comprehensive DFM (Design for Manufacturing) evaluation to optimize your production efficiency. And we provide complimentary DFM (Design for Manufacturing) evaluations for every project.

Please submit your files (STEP, DXF, or IGES) now. Whether it’s a single prototype or a low-volume production run, we provide rapid assessments and technical feedback within hours. Let Samshion Rapid handle the complexity so you can focus on innovation.

Types of Laser Cutting Processes at Samshion

Our advanced facility houses an extensive fleet of high-power fiber laser systems and precision cutting machinery designed to handle diverse industrial applications.

By integrating specialized laser processing techniques, Samshion Rapid ensures optimal edge quality and tight tolerances tailored to specific material properties and thicknesses—delivering perfection from the first prototype to full-scale production.

Inert Gas Laser Cutting

Utilizing high-purity Nitrogen as an inert shielding gas, this process effectively expels molten material from the kerf without reacting with the metal. It is the industrial gold standard for achieving oxide-free edges and superior aesthetics. By eliminating the need for secondary deburring or cleaning, our inert gas cutting service ensures your parts are ready for immediate welding or coating.

Laser Flame Cutting

This leverages an exothermic reaction to significantly boost thermal energy during processing. This high-efficiency method is specifically optimized for thick carbon steel and mild steel plates, delivering rapid cutting speeds and robust structural integrity. While producing characteristic sparks and slag, our specialized service ensures consistent performance and cost-effectiveness for heavy-duty industrial components

Laser Sublimation Cutting

Our laser sublimation cutting employs a high-intensity vaporization process to transition materials directly from solid to gas. This ‘no-melt’ technique is uniquely suited for high-performance polymers like PTFE, PEEK, and intricate textiles, ensuring ultra-precise edges with zero liquid dross. By minimizing the heat-affected zone (HAZ), our sublimation cutting service preserves the chemical integrity and dimensional accuracy of delicate components for specialized industrial applications.

Fiber Laser Fine Cutting

Our fiber laser cutting is engineered for thin sheet metal and intricate geometries, maintaining rigorous tight tolerances of ±0.05 mm. It utilizes short-wavelength technology to deliver exceptional beam quality and narrow kerf widths. This ultra-precision process Perfectly suited for the electronics and medical device industries, our fiber laser service ensures maximum accuracy for complex prototypes and micro-components with a superior edge finish.

Materials of Laser Cutting Services at Samshion

Samshion Rapid provides a comprehensive range of laser cutting solutions tailored for diverse industrial needs. Our engineers utilize high-power fiber laser technology to ensure maximum precision across various material categories.

Metal Laser Cutting (Sheet Metal)

Our core expertise lies in high-speed, high-precision metal fabrication.

Aluminum Laser Cutting: Ideal for lightweight, corrosion-resistant components with clean, burr-free edges. Usually, the thickness of sheet metal is below 8mm.

Stainless Steel Laser Cutting: Delivers sharp, professional finishes for medical, food-grade, and industrial hardware. Usually, the thickness is chosen to be below 5mm.

Carbon & Alloy Steel Cutting: Robust solutions for heavy-duty structural parts and machinery components.

Copper & Brass Cutting: Specialized processing for reflective metals used in electrical and decorative applications.

Plastic & Polymer Laser Cutting

We also offer clean, non-contact cutting for a wide variety of non-metal industrial materials.

Acrylic Laser Cutting: Achieves flame-polished, crystal-clear edges for displays and optical components.

ABS & Polycarbonate Cutting: High-speed shaping for durable enclosures and engineering parts.

High-Performance Polymers (PTFE/Teflon & PEEK): Specialized cutting for high-temperature and chemically resistant materials like PTFE (Teflon) and PEEK, ideal for gaskets, seals, and medical components.

Custom Gasket & Foam Cutting: Precise fabrication of industrial seals, gaskets, and protective packaging inserts.

Our Tolerances in Laser Processing

At Samshion Rapid, we achieve industry-leading laser cutting tolerances typically ranging from ± 0.02 mm to ± 0.15 mm, depending on material type and thickness. We use advanced high-precision fiber lasers and multiple composite processes to ensure consistent size accuracy and repeatability for each batch. And it has strict post-processing processes such as deburring and professional quality inspection to ensure that the prototype of laser cutting has perfect quality.

Optimized Laser Cutting Processes Comparison Table

Cutting Process | Typical Materials | Thickness Range | Standard Tolerance | Superior Tolerance (Fine/Precision) |

Inert Gas Laser Cutting | Stainless Steel, Aluminum, Titanium, High-alloy steels | 0.5 mm – 20 mm (up to 25 mm in some cases) | ±0.10 mm | ±0.05 mm |

Oxygen Flame Cutting | Carbon Steel, Mild Steel | 6 mm – 25 mm+ (up to 40–50 mm with high power) | ±0.20 mm | ±0.15 mm |

Laser Sublimation Cutting | PTFE (Teflon), PEEK, Plastics, Polymers, Wood, Textiles | 0.1 mm – 5 mm (best for thin/delicate) | ±0.08 mm | ±0.05 mm (or tighter on thin materials) |

Fiber Laser Fine Cutting | Thin foils, Electronics-grade metals, Stainless/Aluminum foils, Precision prototypes | 0.05 mm – 2 mm (excels on ultra-thin) | ±0.03 mm | ±0.02 mm (or ±0.01 mm in optimal conditions) |

Estimated Tolerances by Material Thickness – Table

Material Thickness (mm) | Metric Tolerance (mm) | Imperial Tolerance (inch) | Recommended Process |

Thin Gauge (0.05 – 1.5mm) | ±0.03 to ±0.05 mm | ±0.0012″ to ±0.0020″ | Fiber Laser Fine Cutting |

Standard (1.5 – 6.0mm) | ±0.08 to ±0.13 mm | ±0.0030″ to ±0.0050″ | Inert Gas (Nitrogen) |

Medium (6.0 – 12.0mm) | ±0.15 to ±0.20 mm | ±0.0060″ to ±0.0080″ | Nitrogen / Oxygen |

Thick Plate (12.0 – 25mm+) | ±0.25 to ±0.50 mm | ±0.0100″ to ±0.0200″ | Oxygen Flame Cutting |

FAQ

What is the standard precision tolerance for laser cutting?

Samshion Rapid typically achieves industry-leading tolerances between ±0.10 mm and ±0.15 mm. For high-precision requirements, Samshion Rapid utilizes advanced Fiber Laser Fine Cutting to reach an exceptional accuracy of ±0.05 mm on thin-gauge materials. We encourage you to leverage Samshion Rapid’s complimentary DFM review to confirm the tightest possible tolerance for your specific design.

What is the minimum hole size relative to material thickness?

We generally recommend a 1:2 ratio for hole diameter to material thickness to maintain optimal edge quality. However, with high-precision fiber technology, smaller apertures are often achievable. We suggest a quick technical review of your files to confirm the best approach for intricate features.

How to reduce total project costs?

Samshion Rapid focuses on cost-efficiency from the start by providing free DFM (Design for Manufacturing) suggestions with every quote. Samshion Rapid’s engineering team analyzes your part nesting and geometry to minimize material waste and production time, passing those direct savings on to you while maintaining superior quality.

What is the lead time for a typical order?

Speed is a core pillar of us. For standard laser cutting orders with ready-to-use CAD files, we can often deliver functional prototypes within 24 to 48 hours. Samshion Rapid is dedicated to supporting your tightest R&D schedules and production deadlines with reliable, rapid turnaround.

Which file formats does Samshion Rapid prefer for quoting?

To ensure the most accurate and rapid assessment, we prefers 2D files in DXF or DWG for cutting paths, and 3D files in STEP, IGES, or SLDPRT for our comprehensive DFM evaluation. Submitting these formats allows us to provide you with a precise quote and technical feedback in record time. Of course, if you only have a rough idea, you can also provide it in writing, and we can help with the design and drawing.