Precision Molds Manufacturing & Tooling Solutions

Samshion Rapid specializes in high-precision injection mold engineering, delivering custom tooling solutions tailored to your production needs. Combining our advanced CNC infrastructure with an expert design team, we ensure every mold is optimized for durability, cooling efficiency, and high-volume consistency.

Scalable Tooling

Expert solutions for both rapid prototyping and high-volume production molds.

Exceptional Accuracy

Complex geometries with tight tolerances of ±0.02mm.

Turnkey Service

Full integration from DFM analysis to mold trial and final part delivery.

Samshion Manufacturing Process of mold

We don’t just build tools; we engineer production solutions through a specialized four-stage workflow:

- DFM Analysis & Engineering

Before the first cut is made, Samshion Rapid provides a complimentary DFM (Design for Manufacturing) evaluation. We analyze wall thickness, draft angles, and gate locations to prevent defects like sink marks or warping, ensuring your design is optimized for high-yield production.

- Precision CNC & EDM Machining

We carve the mold cavities with extreme precision. For intricate details that cannot be milled, Samshion Rapid employs Electrical Discharge Machining (EDM) to achieve sharp corners and complex textures with tolerances as tight as ±0.0254mm.

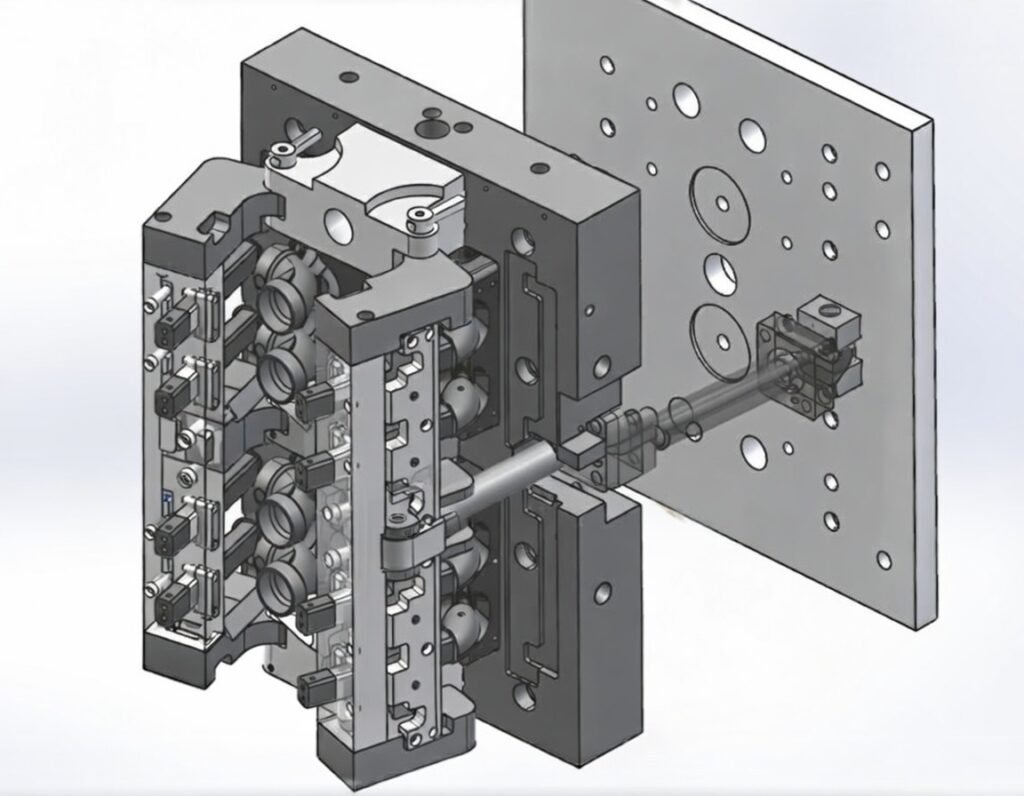

- Multi-Slide & Specialized Tooling

For parts with undercuts or complex side-features, we design and manufacture multi-slide molds. This advanced tooling allows for automated part ejection, reducing cycle times and eliminating the need for expensive secondary operations.

- Mold Trial & Validation

Every tool undergoes a rigorous T1 (first trial) at Samshion Rapid. We provide you with sample parts and a full dimension report to ensure the output perfectly matches your 3D CAD data before the mold is approved for mass production.

Our injection mold types

Single-Cavity Molds

Produces just one part per cycle.

Best For: Large components, complex geometries, or low-volume prototyping.

Multi-Cavity Molds

Produces multiple identical parts per cycle.

Best For: High-volume mass production to minimize unit costs.

Family Molds

Produces different related parts in a single shot.

Best For: Matching sets or assemblies (e.g., top and bottom covers).

Multi-Slide Molds

Features multiple side-actions for complex undercuts.

Best For: Intricate parts requiring side-pulling or multi-directional cores.

Our Common Materials for Injection Molds

In the world of precision manufacturing, the choice of mold material is the single most important factor determining project success. At Samshion Rapid, we don’t just select steel; we engineer solutions. The materials we use directly influence mold lifespan, machining precision, cost-efficiency, and the final aesthetic of your product.

Pre-Hardened Plastic Mold Steels

These steels are supplied pre-hardened (typically 28–40 HRC), so cavities can be machined directly without additional heat treatment. They offer low distortion and are the go-to choice for most molds.

Here are the most popular grades:

Grade | Hardness (HRC) | Polishability | Corrosion Resistance | Wear Resistance | Price Level | Main Applications & Key Features |

P20 / 618 | 28–36 | Medium | Poor | Medium | ★ | General-purpose, best cost-performance for medium/large molds, appliances, housings |

718 / 718H | 30–38 | Medium–Good | Poor | Medium | ★☆ | Improved version of P20; better uniformity, polishing, and EDM performance |

718HH | 34–40 | Good | Poor | Medium–High | ★★ | Balanced choice for higher surface quality requirements |

NAK80 | 37–41 | Excellent | Good | High | ★★★ | Top choice for high mirror polish (phone cases, cosmetics, glossy panels) |

Age-Hardening Stainless Steels

These steels achieve high hardness through specific heat treatments (solution + aging for age-hardening types, or quench + temper for 420). They excel in corrosion resistance (especially the stainless ones) and deliver top-tier mirror polishing for demanding applications like transparent, medical, optical, or glossy parts.

Grade | Type / Treatment | Final Hardness (HRC) | Polishability | Corrosion Resistance | Price Level | Typical Applications & Key Notes |

S136 / S136H | Age-hardening stainless (ESR-refined) | 48–52 (after aging) | Top-tier mirror | ★★★★ | ★★★★ | Highest mirror finish + excellent corrosion (food-grade, medical, transparent PC/PMMA parts); requires heat treatment |

S136ESR | Premium ESR age-hardening stainless | 48–54 | Top-tier mirror | ★★★★★ | ★★★★★ | Ultimate for premium optical/medical + highly corrosive resins (PVC, flame-retardant, acidic); best purity & polish |

2083ESR | ESR age-hardening stainless | 46–52 | Top-tier | ★★★★☆ | ★★★★☆ | High-end mirror + strong corrosion resistance; often slightly better value/performance ratio than standard S136 |

420 (AISI 420 / 1.2085) | Martensitic stainless (quench & temper) | 48–54 (after HT) | Excellent–Top-tier mirror | ★★★★ | ★★★ | Good corrosion resistance for moisture/corrosive plastics; secondary choice for high-transparency/mirror after S136; more affordable stainless option, widely used in medical/food molds |

Aluminum Alloys

Aluminum (e.g., 7075) are ideal for rapid prototyping and shorter production cycles. They offer exceptional thermal conductivity and superior machinability, significantly reducing lead times and cooling cycles. While they possess lower hardness, their ability to dissipate heat quickly makes them indispensable for optimizing cycle efficiency and managing complex thermal zones in precision molding.

Material | Hardness (HB) | Thermal Conductivity | Typical Mold Life (cycles) | Price Level | Main Uses |

7075 Aluminum | 150–180 | ★★★★★ | 5,000–200,000 | ★☆ | Rapid prototyping, structural testing, clear parts, low–medium volume |

6082 Aluminum | 90–120 | ★★★★☆ | 3,000–100,000 | ★ | Budget aluminum option for lower surface requirements |

Aluminum + Hard Chrome Plating | — | ★★★★ | 10,000–300,000 | ★★ | Extended life aluminum solution |

FAQ

What is the typical lead time for a custom injection mold?

At Samshion, lead times are strategically managed based on the complexity, cavitation, and precision requirements of the project. We categorize our production timelines into three tiers to help you plan your market launch effectively:

Rapid Prototyping & Simple Molds (1–3 Weeks): Ideal for single-cavity tools with simple open-and-shut geometries. These are often used for bridge production or functional testing using production-grade resins.

Productions Molds (3–5 Weeks) :This is our most common timeframe for multi-cavity tools featuring standard mechanical components like sliders and lifters. This type of mold is typically used for products in consumer electronics, industrial components, and household products.

High-Complexity & Precision Molds (5–10+ Weeks): Reserved for highly engineered solutions, including 2K (multi-shot) molds, automatic unscrewing mechanisms, or ultra-high-precision medical components. These timelines account for rigorous steel heat treatment, complex EDM (Electrical Discharge Machining), and extensive T1 validation.These schedules include the process of steel heat treatment, complex electrical discharge machining (EDM) after CNC milling, and rigorous T1 verification

How does Samshion guarantee mold quality and provide long-term support?

At Samshion, our commitment to quality extends far beyond the shipping docks. We ensure excellence through a combination of rigorous In-Process Control and our dedicated Overseas Technical Support.

1. Engineering & Process Precision

Scientific Validation: We utilize Moldflow Analysis and Scientific Molding (DOE) to ensure the mold operates within a stable “processing window,” minimizing defects like warpage or flash.

CMM Verification: Every critical component is verified via Coordinate Measuring Machines (CMM) to tolerances as tight as ±0.005mm before assembly.

Traceability: We provide full certification for all premium steels (LKM, Assab) and standardized components (HASCO, DME).

2. Global After-Sales & On-Site Support

We understand that downtime is costly. Unlike traditional exporters, we provides a “Global Safety Net” for your production:

Overseas Engineering Service Team: We maintain a mobile team of experienced field engineers capable of providing on-site support at your facility. Whether it is final mold commissioning, troubleshooting complex mechanical issues, or performing emergency repairs, our experts are available to fly to your location.

24/7 Remote Technical Assistance: Our technical hotline is staffed by senior mold designers who can provide immediate video-call diagnostics to solve production hiccups in real-time.

Rapid Spare Parts Response: We maintain a digital twin of every mold built. If a component is damaged, we can CNC-machined a replacement using the original CAD data and air-freight it to you within days.

Comprehensive Warranty: Every Samshion mold is backed by a performance guarantee. We stand by our cycle time promises and tool-life ratings.

How do we mitigate "Vacuum Voids" and internal stress in thick-walled transparent parts, such as optical lenses or luxury packaging?

Thick-walled parts suffer from extreme thermal gradients. Samshion Rapid solve this using 3D-printed Conformal Cooling channels integrated with high-conductivity Beryllium Copper inserts. This allows the cooling water to follow the exact contour of the part at a constant distance, ensuring uniform heat extraction. This precision thermal management eliminates vacuum shrinkage and ensures the optical clarity required for premium applications.

How do you protect my Intellectual Property (IP) and proprietary designs?

IP security is a cornerstone of our partnership. Our team will protect your intellectual property through the following measures.

Data Segregation: Your design files are stored on secured, encrypted servers with restricted access.

Legal Protection: We sign comprehensive Non-Disclosure Agreements (NDA) and can work with “masked” part names to ensure project confidentiality within our facility.

Secure Disposal: All scrap steel or rejected samples from the trial phase are destroyed to prevent any design leaks.