Comprehensive Manufacturing Services with Samshion

At Samshion, we offer an extensive range of manufacturing services designed to meet the needs of various industries. From precision CNC machining, 3D printing, sheet metal fabrication, injection molding, to rapid prototyping and low-volume production, we cover every stage of your product development.

Full Range of Manufacturing Technologies at Your Fingertips

At Samshion, we deliver industry-leading precision manufacturing solutions from prototype to production. Our advanced facilities and skilled engineers ensure every part meets exact specifications and quality standards. We provide fast turnaround and competitive pricing on custom parts for customers worldwide.

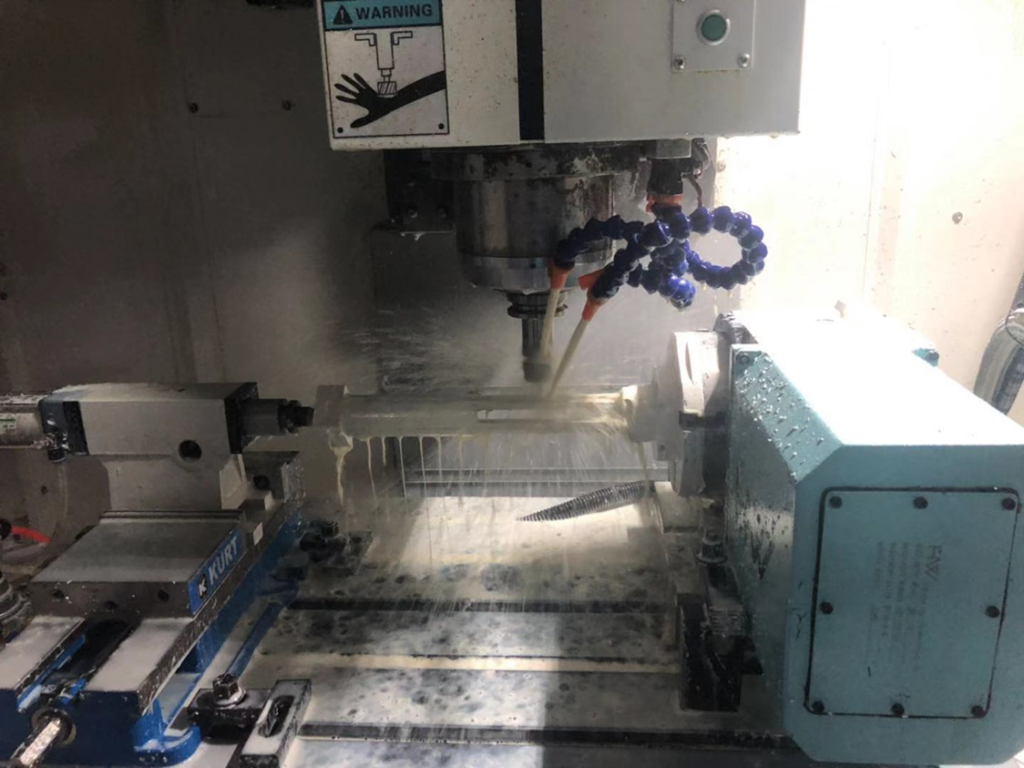

CNC Machining

Samshion’s CNC machining services provide high-precision components through advanced subtractive manufacturing techniques. Using state-of-the-art multi-axis mills and lathes, we machine parts in metals and plastics with tight tolerances and fine surface finishes. This process is well-suited for both functional prototypes and large-scale production runs, delivering durable and accurate parts for industries such as aerospace, automotive, and medical. Our experienced machining team optimizes toolpaths and cutting strategies to ensure efficiency, consistent quality, and short lead times on every job.

CNC Milling

Our CNC milling delivers components with intricate contours and surface finishes up to Ra 0.4μm. Perfect for molds, brackets, and functional prototypes.

CNC Turning

CNC turning creates exact cylindrical components like shafts, bushings, and sleeves through automated rotational machining. Ideal for high-tolerance axisymmetric parts.

5-Axis CNC Machining

5-axis simultaneous machining enables complex geometries in single setup. Optimal for aerospace components, medical devices, and turbine blades.

Additive Manufacturing

Our additive manufacturing capabilities (3D printing) enable the production of complex, lightweight parts that are often impossible to make with traditional methods. We offer a range of technologies and materials, including metals and plastics, to match your performance requirements. This technology is ideal for rapid prototyping, design validation, and low-volume production parts, allowing quick iterations and minimal tooling costs. Clients benefit from accelerated development cycles and significant cost savings on intricate or customized components.

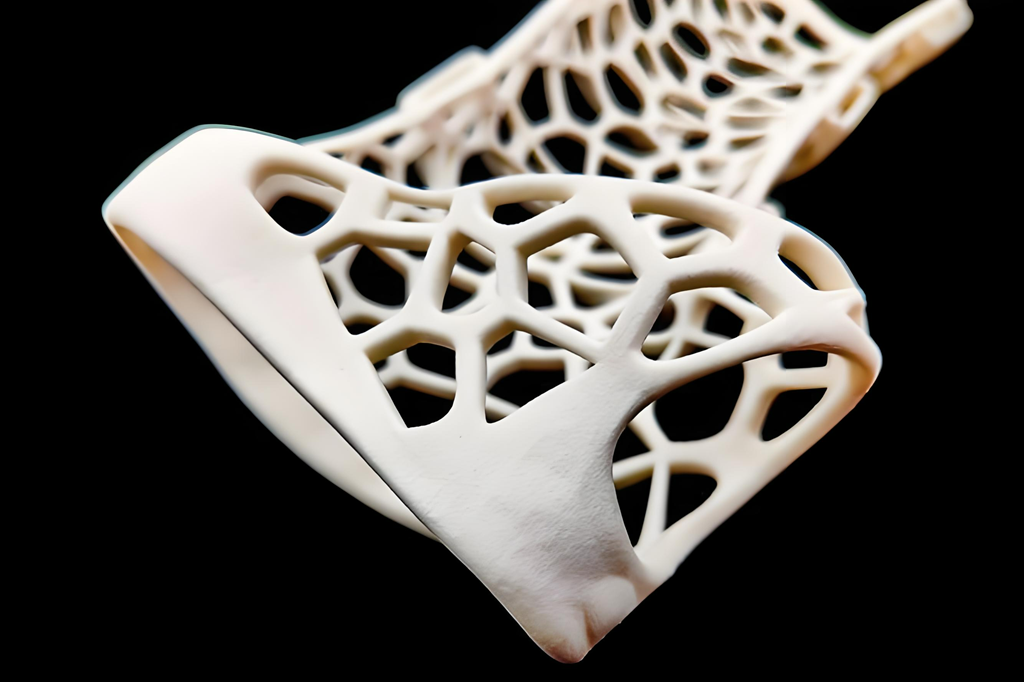

Stereolithography (SLA)

SLA employs UV lasers to cure liquid resin into ultra-smooth, detailed components, perfect for intricate prototypes and visual models requiring flawless surface finishes.

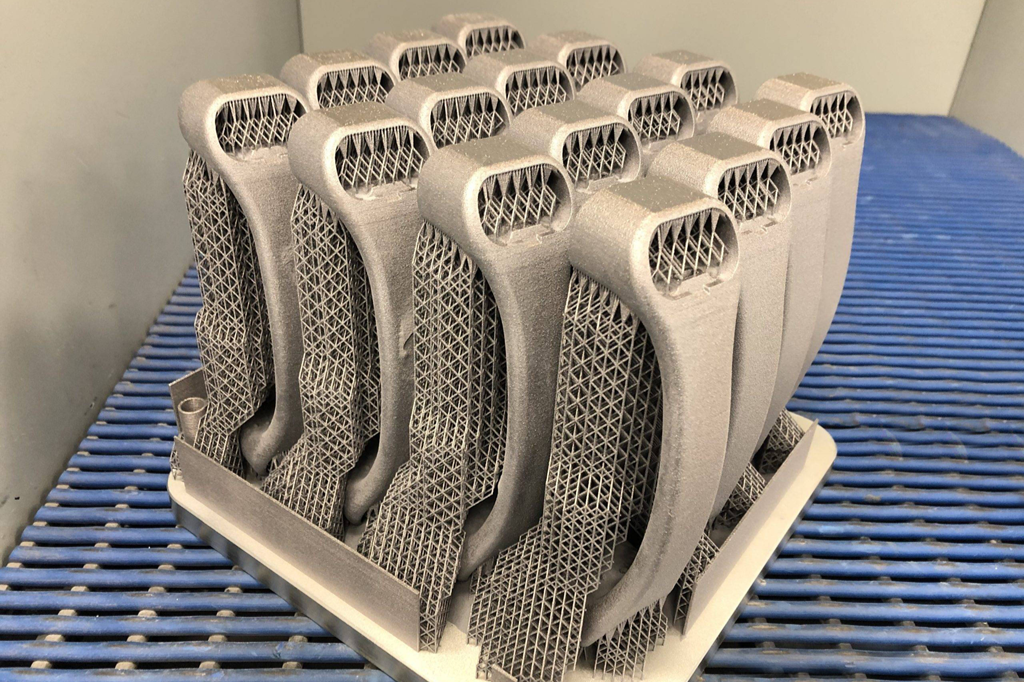

Selective Laser Sintering (SLS)

SLS uses precision lasers to sinter polymer powders, creating lightweight yet robust parts ideal for complex designs and end-use components in demanding environments.

Selective laser melting(SLM)

SLM melts metal powders layer by layer to craft high-density, precision metal parts optimized for aerospace, medical, and industrial applications requiring extreme durability.

Sheet Metal Fabrication

Our sheet metal fabrication services transform flat metal sheets into durable, functional components and assemblies. We cut, bend, punch, and weld steel, aluminum, and other alloys to build enclosures, panels, brackets, and frames according to your designs. This method is highly cost-effective for high-volume production of robust components used in equipment housings, structural frameworks, and custom panels. With precision bending and automated laser cutting, Samshion delivers consistent quality, precise angles, and fast delivery for every project.

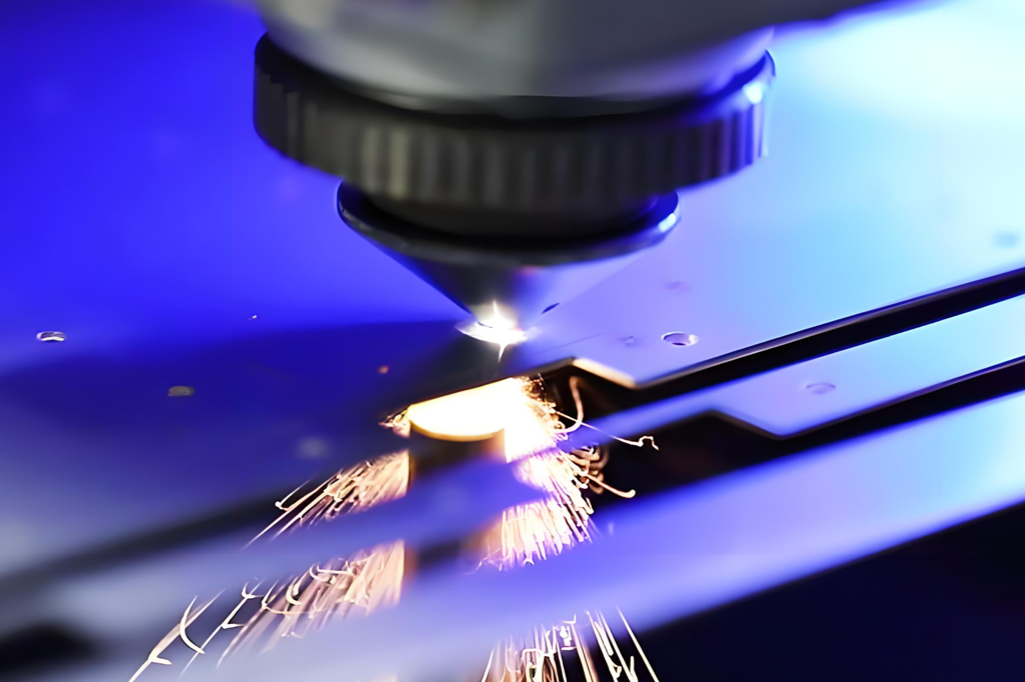

Laser Cutting

Laser cutting employs a high-intensity beam to precisely cut, etch, or engrave materials, achieving intricate patterns and smooth edges as per design specifications. This method is ideal for complex geometries and tight tolerances, making it a top choice for industries requiring detailed and durable metal components.

Bending

Bending reshapes thin metal sheets into desired forms such as U-channels, V-angles, or custom profiles using controlled force. Capable of handling varying material thicknesses, this process ensures consistent results for both structural and aesthetic applications.

Welding

Welding combines heat and pressure to fuse metal pieces into robust, long-lasting assemblies. Our expertise in MIG, TIG, and spot welding techniques guarantees strong, seamless joints for critical applications across automotive, aerospace, and industrial sectors.

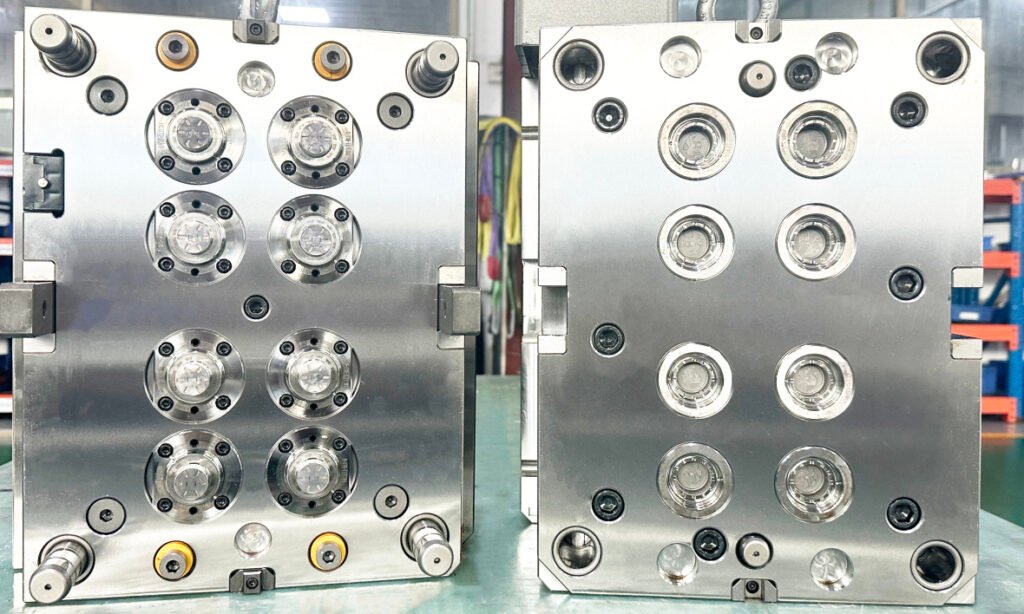

Injection Molding services

Samshion’s injection molding services offer high-precision plastic parts for mass production with exceptional consistency and surface finish. We provide both prototype and production-grade molds to suit your project needs — from rapid prototyping to large-scale manufacturing.

Our experienced team assists with material selection, mold design, and production optimization to ensure cost-effective solutions and outstanding product quality. Applications include automotive components, consumer products, medical devices, and industrial enclosures.

Rapid Tooling

Bridge tooling provides a fast and economical solution for producing injection mold tools to support low- to medium-volume production before full-scale tooling investment.

Production Molds

We provide durable, high-precision production molds optimized for large-scale manufacturing. Engineered for exceptional repeatability and part consistency, our molds ensure cost-efficiency in long-term plastic component production.

Other Manufacturing Services

Beyond CNC machining and injection molding, Samshion offers a range of specialized rapid manufacturing services to meet diverse production needs:

Vacuum Casting

Ideal for low-volume production and functional prototypes, vacuum casting delivers high-quality plastic parts with excellent surface finishes and material properties similar to injection-molded parts.

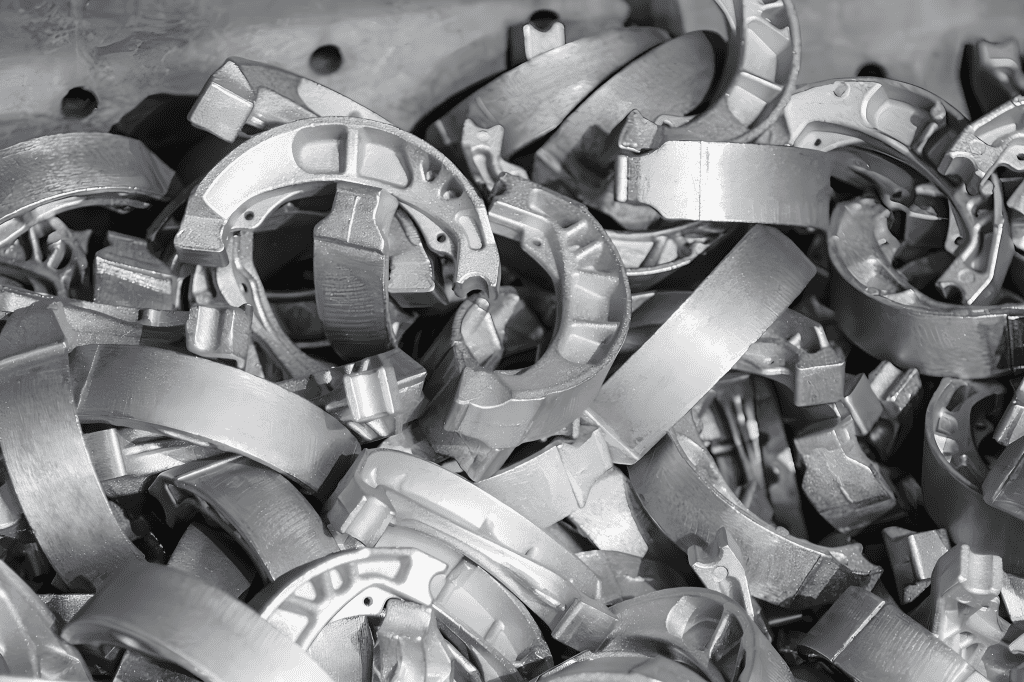

Rapid Die Casting

Our rapid die casting service produces precise metal components (such as aluminum, zinc alloys) with superior strength and dimensional accuracy, suitable for both prototypes and small-batch production.

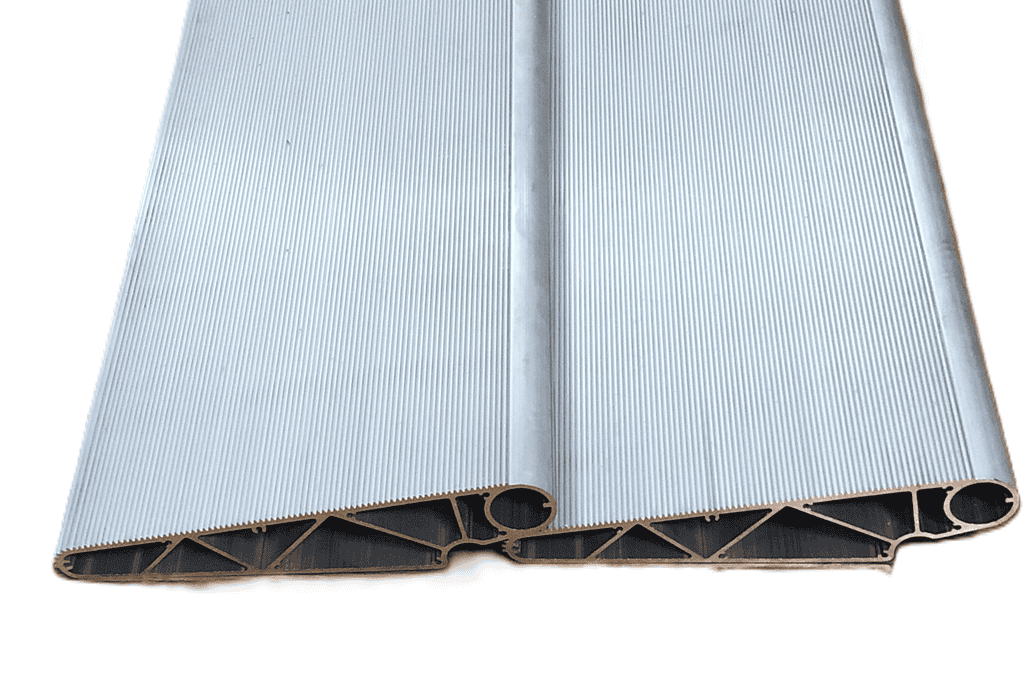

Aluminum Extrusion

We provide precision aluminum extrusion services for custom profiles, ensuring tight tolerances and high surface quality. Suitable for structural components, frames, and heat sinks.

Why Work with Samshion

- ISO-Certified Quality: We follow strict quality management processes to ensure consistent, high-grade parts.

- End-to-End Support: From design review to production and inspection, our engineers guide your project at every stage.

- Rapid Turnaround: Online quoting and optimized workflows mean fast lead times, even for complex projects.

- Global Delivery: Serving customers worldwide, we offer flexible logistics and communication in multiple languages.

Choose Samshion as your precision manufacturing partner to benefit from cutting-edge technology, expert support, and unwavering quality.

Ready to get started? Get an Instant Quote or Contact Us to discuss your project and see how Samshion can help bring your designs to life.