Quality Assurance

Our operations adhere to a stringent ISO 9001:2015-certified quality management system, underscoring our dedication to continuous improvement and exceptional customer satisfaction. Through rigorous process controls and real-time monitoring, we ensure every project meets global standards for precision, reliability, and compliance.

- Finished product pass rate: ≥98%

- On-time delivery rate: ≥95%

- Customer satisfaction score: ≥95/100

Comprehensive Quality Control Systems for Reliable Manufacturing

Samshion has a complete metrology lab and well trained quality engineers and technicians to ensure dimensional accuracy, visual quality, and repeatability. Under our ISO9001:2015 certification, we equip with powerful quality inspection tools which covers from Process Control Plans (PCPs), FMEAs, to part by part work instructions, parameter sheets and standardized workflows. With these,it enables us to consistently produce parts with consistency and timeliness as well as mitigate the risk.

By integrating advanced inspection technologies (CMM, optical comparators) and proactive quality audits, we minimize defects, optimize workflows, and exceed client expectations across prototyping, low-volume, and high-volume production phases.

We implement rigorous quality assurance protocols to ensure consistency across every component, product, and project. Our commitment extends from meticulous design validation to proactive process innovation, supported by cutting-edge technology and a skilled team dedicated to precision rapid manufacturing.

Every project undergoes Design for Manufacturing (DFM) analysis to optimize producibility, followed by contract reviews and production capacity assessments (PMC) to align resources with your timeline. Raw materials are inspected for compliance, while in-process quality checks (IPQC) and real-time monitoring minimize deviations. Nonconforming products trigger corrective actions, and final inspections (OQC) deliver certified test reports for traceability. Ensuring we exceed expectations in material selection, turnaround, and technical collaboration.

Advanced Inspection Technologies for Precision Manufacturing

We utilize cutting-edge inspection systems to ensure flawless component quality, compliance with stringent specifications, and full traceability throughout production. Our advanced metrology tools validate dimensional accuracy, detect micro-defects, and align every part with your design intent.

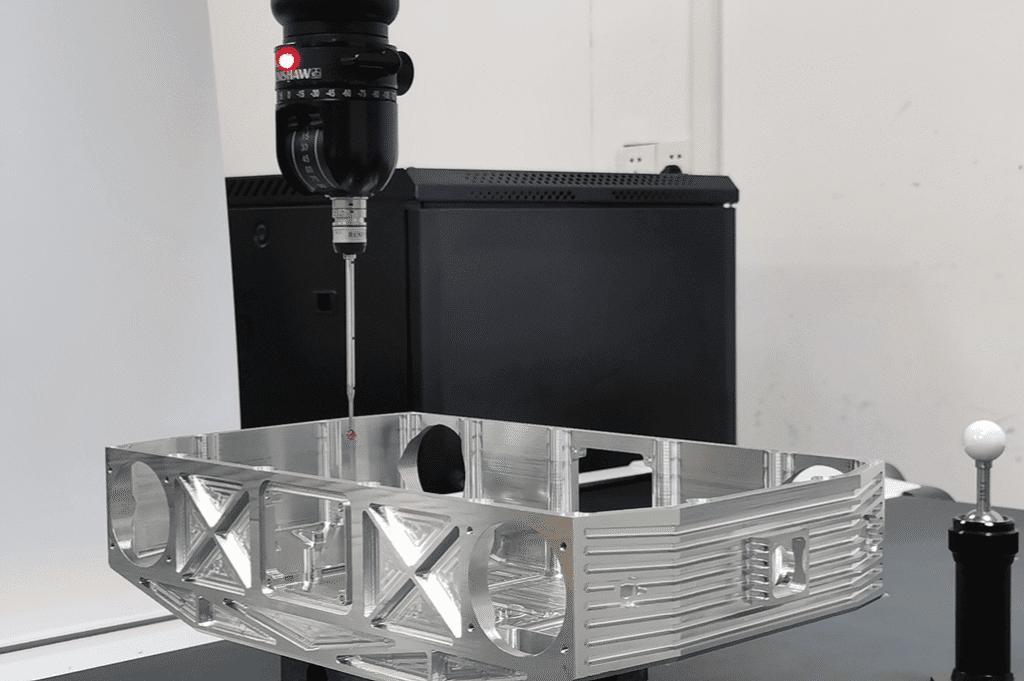

Coordinate Measuring Machines (CMM)

CMM systems deliver micron-level precision in verifying complex geometries, critical tolerances, and surface profiles. Our engineers tailor inspection protocols to your components, cross-referencing 3D CAD models to ensure compliance with ISO and industry-specific standards. Automated CMM workflows enable rapid, repeatable measurements for prototypes, machined parts, and assemblies, minimizing human error and accelerating time-to-market.

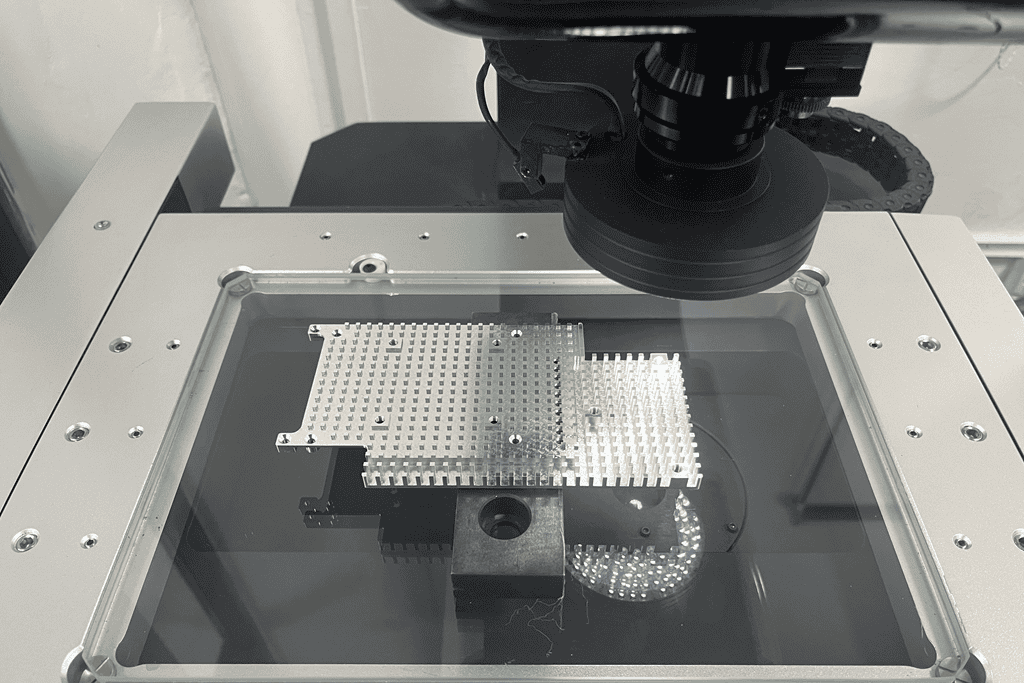

Optical Measurement Systems

Non-contact optical systems employ high-pixel cameras and AI-driven software to perform rapid, precise 2D/3D measurements. Capable of edge detection, surface roughness analysis, and automated defect recognition, these tools ensure consistency across high-volume production. Advanced algorithms support complex calculations, while real-time data logging enhances traceability for industries requiring rigorous quality audits.

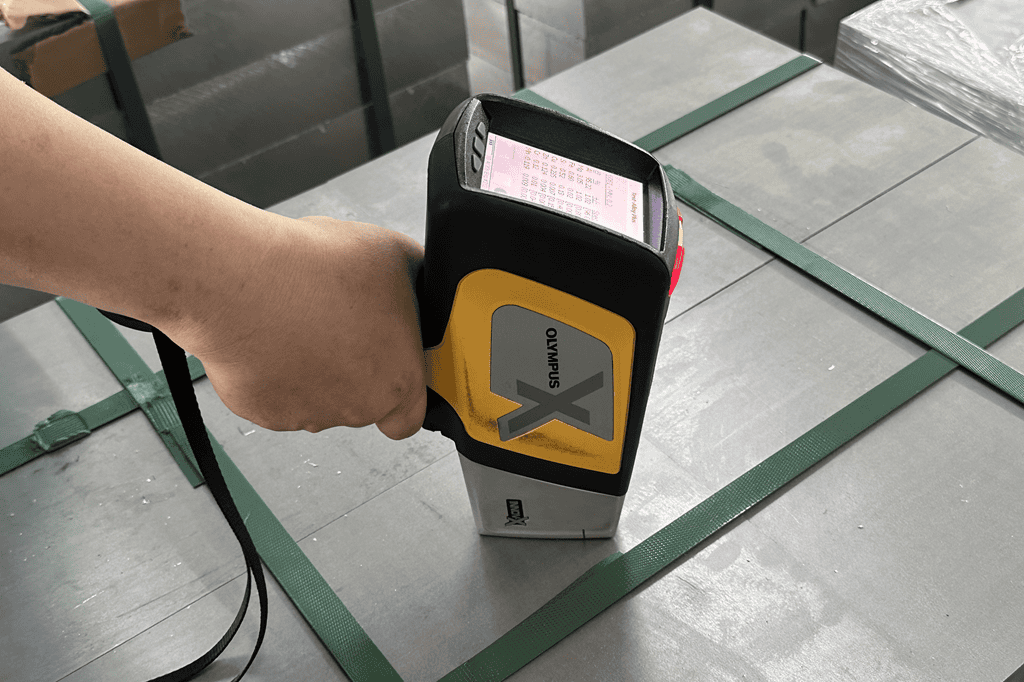

Optical Emission Spectrometry (OES)

Our state-of-the-art Optical Emission Spectrometer (OES) ensures 100% material traceability and compliance by accurately identifying and verifying the chemical composition of all incoming metals. With precision exceeding 98%, this advanced system detects alloy grades, elemental concentrations, and impurities, guaranteeing that every raw material aligns with your specified standards. Ideal for aerospace, automotive, and industrial applications, our OES technology eliminates risks of material mismatches, enhances quality control workflows, and supports ISO-certified manufacturing processes.

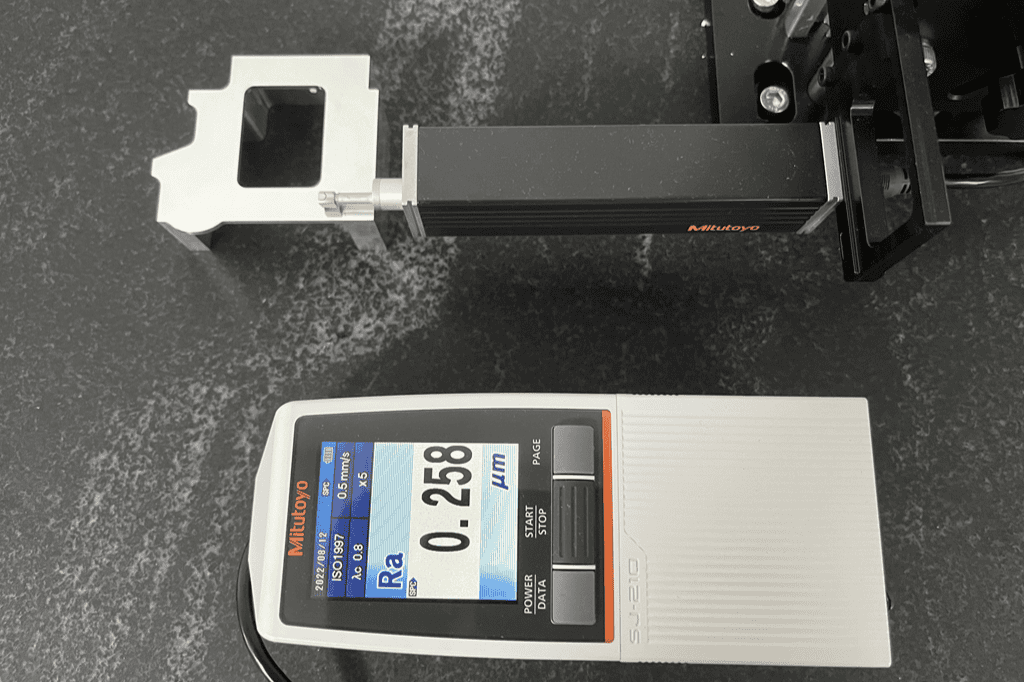

Surface Roughness Measurement

Our Mitutoyo surface roughness testers deliver micron-level accuracy in evaluating part surface profiles, ensuring compliance with critical Ra, Rz, and Rq specifications. Equipped with advanced contact and non-contact probes, these instruments analyze texture, waviness, and finish consistency across metals, plastics, and composites. Ideal for automotive, aerospace, and medical device manufacturing, our ISO-certified inspection processes validate adherence to industry standards (e.g., ISO 4287, ASME B46.1), minimizing friction, wear, and performance risks in end-use components. Real-time data logging and customizable reporting streamline quality audits, while automated calibration guarantees repeatability for high-volume production environments.

Comprehensive Quality Documentation & Inspection Services

We deliver full-spectrum quality documentation, including detailed inspection reports, material compliance certificates, and regulatory documentation, ensuring transparency and traceability for every project. Our visual inspection protocols verify color accuracy, surface texture, and aesthetic integrity against client specifications, utilizing calibrated lighting systems and digital imaging tools for objective assessments.

For dimensional validation, precision instruments (vernier calipers, micrometers, CMMs) measure simple to complex geometries, achieving tolerances as tight as ±0.01mm. Performance testing evaluates functional aspects like thread fitment, assembly compatibility, and stress resistance under simulated operating conditions.

First Article Inspection (FAI) reports provide exhaustive records of initial production samples, covering all inspection stages from raw material checks to final part validation. Upon request, we supply RoHS compliance certificates and full material disclosure (FMD) reports, confirming adherence to international environmental and safety standards.

Scientific management

Establish standardized and scientific management concepts;

Develop reasonable working procedures and operating standards;

Cultivate excellent employees with first-class skills;

Improve production efficiency.

Lean production

Based on customer expectations and values, we continue to strengthen production planning management, production process optimization, supply chain coordination optimization, production cost control, staff quality and other aspects of operation management. Continuously improve ourselves so that continuously improve customer satisfaction.

High efficiency and quality

Through the implementation of the quality management system, we strengthen quality control and inspection in each process of the production and ensure effective communication between customers and all departments.At the same time, we also train the employees’ quality awareness, continuously promote the technology’s upgrading so as to efficiently manufacture high-quality products.

Encouragement and innovation

Establish a learning organization system,

implement scientific management,

collect and sort out corrective and preventive measures knowledge, production technology, business data or production experience coming from professional and technical personnel or departments,

form an important valuable resource of the company,

provide continuous training and summary for employees,

encourage innovation and enhance the competitiveness of the company.