Precision Aluminum CNC Machining for Prototypes & Production

Explore precision-machined aluminum parts with rapid lead times and cost-effective rates. Select from various alloys (6061, 7075) and surface finishes for high-quality prototypes or end-use components.

- No Minimum Order Quantity

- ISO 9001:2015 Certified

- 24/7 Technical Support

Expert Aluminum Machining Services

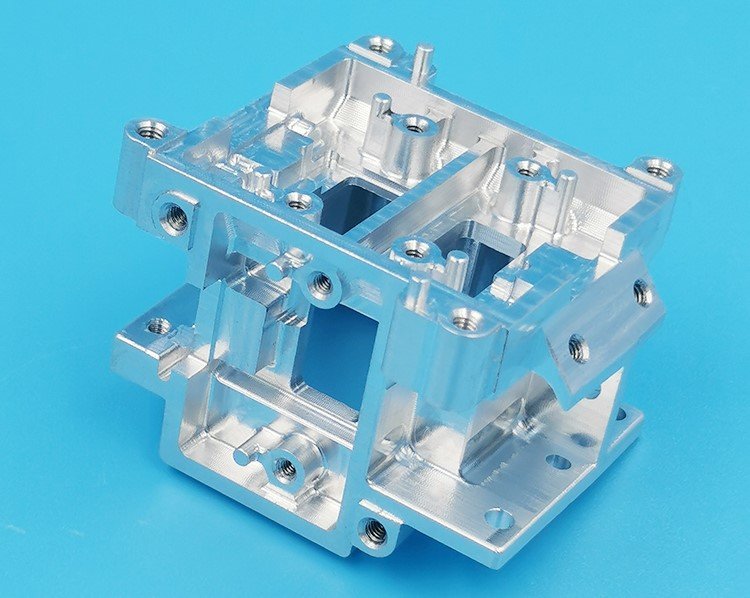

Lightweight aluminum parts drive aerospace, automotive, and robotics innovation. With 15+ years of expertise, Samshion masters precision CNC aluminum machining.

We specialize in custom, complex aluminum parts with tight tolerances. Our commitment to quality ensures consistent results for prototypes and end-use production.

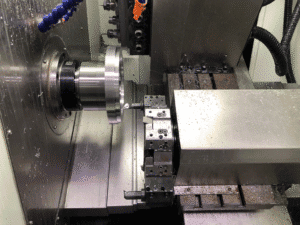

Advanced CNC machines and skilled technicians drive our competitive edge. Continuous upgrades and process optimizations guarantee efficiency and client satisfaction.

Why Choose Samshion for Aluminum Machining Services

No Minimum Order Quantity

Prototypes or bulk production – Samshion handles orders of any size, from single units to 10,000+ parts.

Expert Engineering Team

Samshion’s engineers specialize in aerospace, medical, and automotive projects, solving complex design challenges.

Industry-Competitive Pricing

Optimized CNC processes and in-house tooling reduce costs. We match or beat market rates for precision aluminum parts.

Tight Tolerances (±0.01mm)

Aerospace-grade quality control with Renishaw probes and temperature-controlled facilities. Ideal for AS9100-certified components.

Rapid Turnaround

50+ advanced CNC machines ensure 30% faster lead times vs. industry averages – from design to delivery.

Custom Surface Finishes

Anodizing, chromating, powder coating, and media blasting options to meet functional or aesthetic requirements.

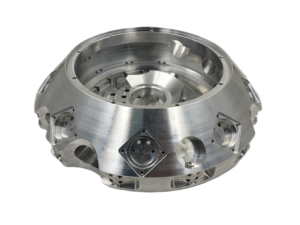

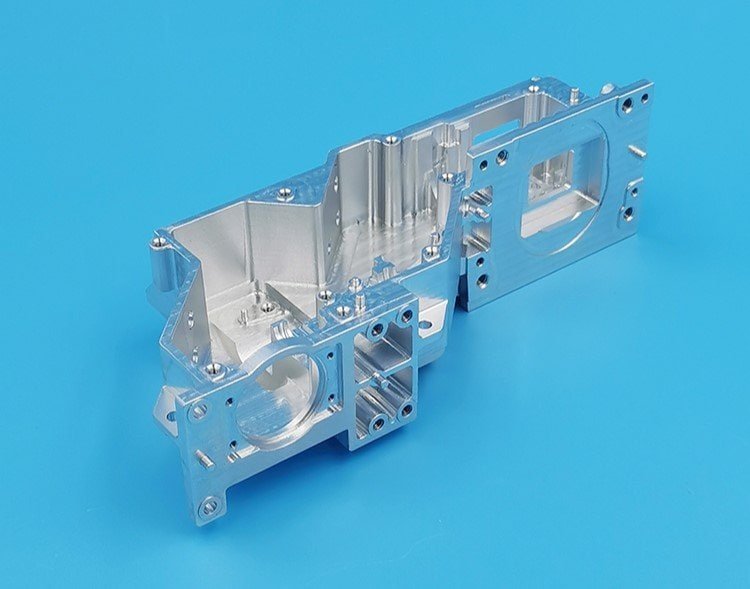

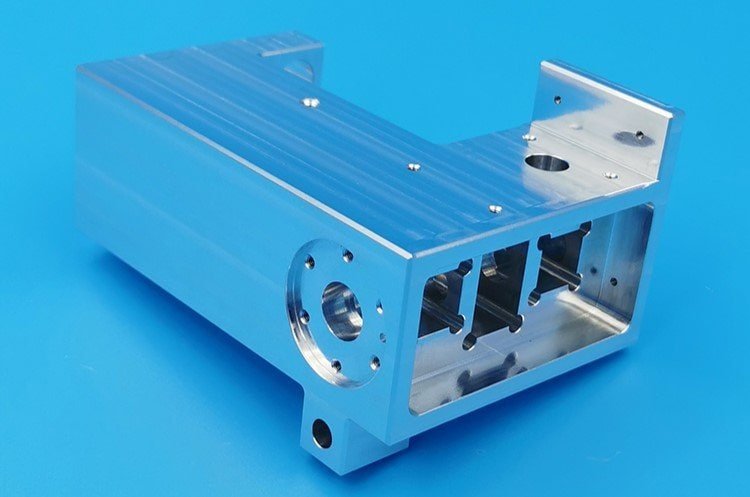

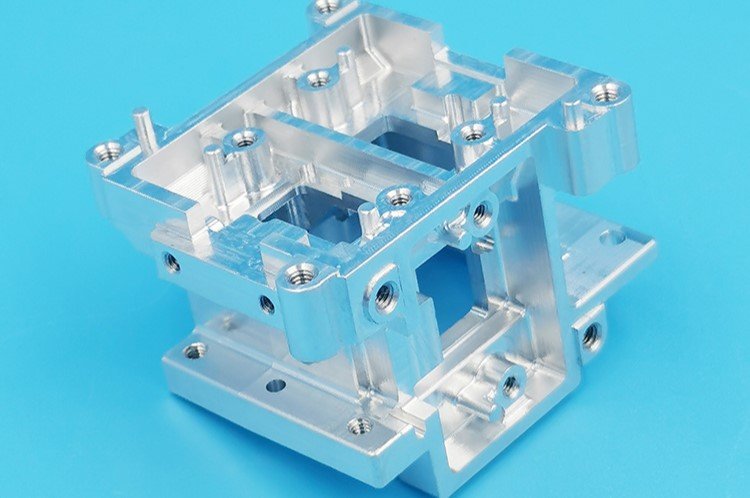

Comprehensive Aluminum Machining Solutions

Aluminum CNC machining rarely operates in isolation. For batch orders exceeding hundreds of units, Samshion provides end-to-end processes to maximize efficiency, precision, and cost-effectiveness.

We analyze part complexity, manufacturability, and budget to design tailored process routes. Samshion’s engineers optimize every step to align with your specifications and timelines.

Our integrated capabilities include 3/4/5-axis CNC milling, turning, EDM, wire EDM, and casting/extrusion technologies. This multi-process approach tackles complex aluminum parts while slashing production costs.

Advantages of Aluminum Machining with Samshion

Aluminum dominates global manufacturing due to its unmatched versatility. Samshion leverages these 5 core advantages for precision CNC projects:

Machining Efficiency

Aluminum’s softness enables 3x faster CNC speeds vs. titanium. Samshion achieves complex geometries (±0.02mm) with reduced tool wear.

Lightweight Strength

At 2.7 g/cm³ density, aluminum reduces component weight by 50% vs. steel. Ideal for aerospace frames, automotive panels, and portable medical devices.

Superior Corrosion Resistance

Samshion enhances natural oxidation resistance through anodizing, powder coating, and chromating – extending part lifespan in marine/chemical environments.

Cryogenic Stability

Maintains mechanical properties below -150°C – perfect for space exploration hardware and LNG storage systems.

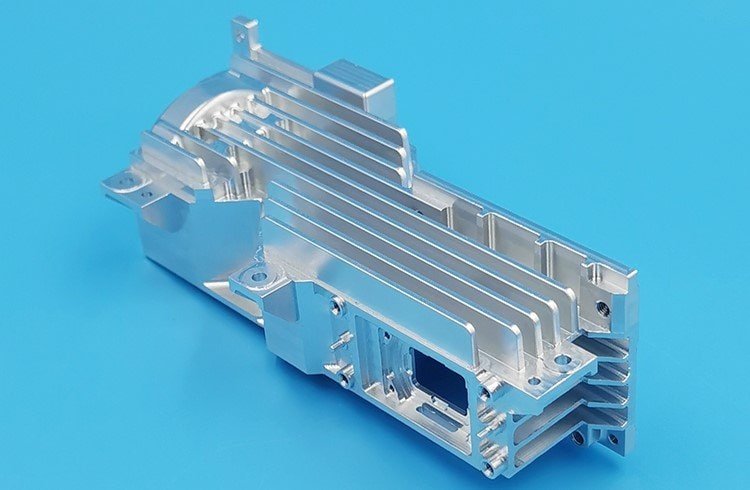

High Thermal & Electrical Conductivity

With 235 W/m·K thermal conductivity, Samshion-machined aluminum optimizes heat sinks, EV battery housings, and electrical enclosures.

CNC Aluminum Prototyping

Aluminum CNC prototyping accelerates design validation and pre-production testing, ensuring seamless transition to mass manufacturing. Identify and resolve issues faster with Samshion’s solutions.

Our in-house process delivers efficient, precise, and budget-friendly aluminum prototypes. Samshion’s engineers analyze designs and integrate specialized processes (welding, EDM, wire EDM) for optimal results.

Rigorous validation ensures alignment with your budget, timeline, and material goals. Trust Samshion to refine your prototypes before full-scale production.

Precision Custom Aluminum Parts

Samshion combines advanced technology, ISO9001 compliance, and flexible engineering to provide affordable, high-quality aluminum machining solutions. We execute complex projects rapidly without compromising precision or product integrity.

Our in-house capabilities include custom surface treatments: sandblasting, polishing, electrophoresis, anodizing, powder coating, and painting. Trust Samshion for prototypes or large-scale production with guaranteed consistency.

Samshion’s Aluminum Material Expertise

Choosing aluminum for CNC machining offers unmatched versatility, but selecting the ideal grade for your project can be challenging. Samshion’s engineers turn complexity into clarity.

With decades of material science experience, we streamline aluminum grade selection. Our team analyzes mechanical properties, corrosion resistance, and cost-efficiency to match your goals.

Below are key aluminum grades we specialize in for precision machining:

Aluminum 6061

As the most versatile heat-treatable alloy, Samshion’s 6061 retains aluminum’s core benefits: lightweight, corrosion resistance, and excellent workability. Its adaptable mechanical properties suit automotive brackets, marine fittings, and functional prototypes.

Aluminum 6063

6063 dominates architectural applications due to its smooth surface finish and extrusion capabilities. Used for window frames, LED housings, and decorative trims, it combines aesthetics with durability.

Aluminum 6082

6082 delivers the highest strength in the 6000 series, ideal for load-bearing parts. With enhanced corrosion resistance, it replaces 6061 in CNC-machined industrial frames, robotic arms, and hydraulic system components.

Aluminum 7075

7075 is a premium aerospace-grade alloy with unmatched strength (570+ MPa). Ideal for aircraft fittings, drone frames, and defense components requiring extreme durability. Machined with 5-axis CNC for complex geometries.

Aluminum 2024

2024 balances high strength-to-weight ratios and fatigue resistance. Used in aircraft rivets and structural parts. Not weldable; we recommend chromate coatings for corrosion protection.

Aluminum 5052

5052 dominates marine applications with exceptional saltwater corrosion resistance. Perfect for ship hulls, offshore platforms, and food-grade machinery. Easily formed and welded.

| Aluminum Grade | Cost | Ultimate Tensile Strength | Max Temp (°C) | Elongation (%) | Hardness | Weldability | Thermal Conductivity (W/m·°C) | Common Applications |

|---|---|---|---|---|---|---|---|---|

| 6061-T6 | $ | 290-320 MPa | 130-150 | 12-17 | 60 HRB | High | 152-169 | Automotive, Marine, Frames |

| 7075-T6 | $$$ | 434-580 MPa | 100 | 2-11 | 79-86 HRB | Poor | 131-137 | Aerospace, High-Stress Parts |

| 7050 | $$$$ | 490-550 MPa | 120 | 8-12 | 85-90 HRB | Low | 130-140 | Military, Aircraft Structures |

| 2024-T3 | $$ | 325-470 MPa | 110 | 10-18 | 70-75 HRB | Moderate | 121-138 | Aircraft Fuselage, Fasteners |

| 2A12 | $$ | 390-440 MPa | 100 | 6-10 | 75-80 HRB | Moderate | 125-135 | Industrial Machinery |

| 6082 | $ | 140-340 MPa | 130-150 | 6-18 | 35-56 HRB | High | 160-180 | Structural Components |

| 5083-H32 | $$ | 270-350 MPa | 80-100 | 13 | 74 HV | High | 118-128 | Marine, Pressure Vessels |

| 5052-H32 | $ | 193-290 MPa | 90-110 | 12-20 | 50-60 HRB | High | 138-150 | Shipbuilding, Vehicle Panels |

| 6063-T5 | $ | 130-240 MPa | 120-140 | 8-14 | 45-55 HRB | High | 190-210 | Architectural Extrusions |

| MIC6 (Cast) | $$$ | 165-200 MPa | 150 | 2-4 | 70-80 HB | Low | 140-155 | Precision Jigs, Flat Plates |

Note: Data provided is for reference. Contact Samshion for project-specific material certifications and technical specifications.