Vacuum Casting Services

Professional online urethane casting services for prototypes and end-use production parts. Deliver precision-engineered components with intricate geometries, tight tolerances, and exceptional surface finishes. Ideal for short-run manufacturing, our process ensures production-level quality at competitive lead times, bridging the gap between prototyping and full-scale production.

What is Vacuum Casting?

Vacuum casting is a precision manufacturing method that replicates master patterns using polyurethane resins, starting with a silicone mold crafted from a 3D-printed original. By casting parts under vacuum pressure, this process eliminates air bubbles and achieves intricate, high-quality results comparable to injection molding—but with shorter lead times and lower costs. It is ideal for functional prototypes, small-batch production, and end-use parts requiring exceptional detail and durability.

At Samshion, we elevate vacuum casting technology by ensuring dimensional accuracy with minimal shrinkage (±0.1%), even for components up to 25 inches. Our advanced processes support tight tolerances for complex geometries and diverse material properties, including transparent, flexible, or heat-resistant resins. We also embed custom inserts (e.g., metal threads, sensors) during casting and offer specialized finishes like UV coatings or textured surfaces to meet unique design requirements.

Samshion’s vacuum casting services provide a seamless transition from prototyping to mid-volume production, bypassing the high tooling costs and delays of traditional injection molding. With rapid turnaround and rigorous quality control, we deliver cost-efficient, production-grade parts tailored to industries ranging from automotive to consumer electronics.

How Urethane Casting Works?

The urethane casting process involves three key stages: master pattern creation, mold fabrication, and urethane casting.

Stage 1. Master Pattern Development

The accuracy and finish of final urethane parts depend on the quality of the master pattern. CNC machining is preferred for tight tolerances, glossy surfaces, or optically clear finishes, while SLA 3D printing is ideal for intricate geometries. Surface treatments like texturing or satin coatings can replicate final product aesthetics. Silicone molds capture these details, ensuring cast parts mirror the master’s design without additional post-processing.

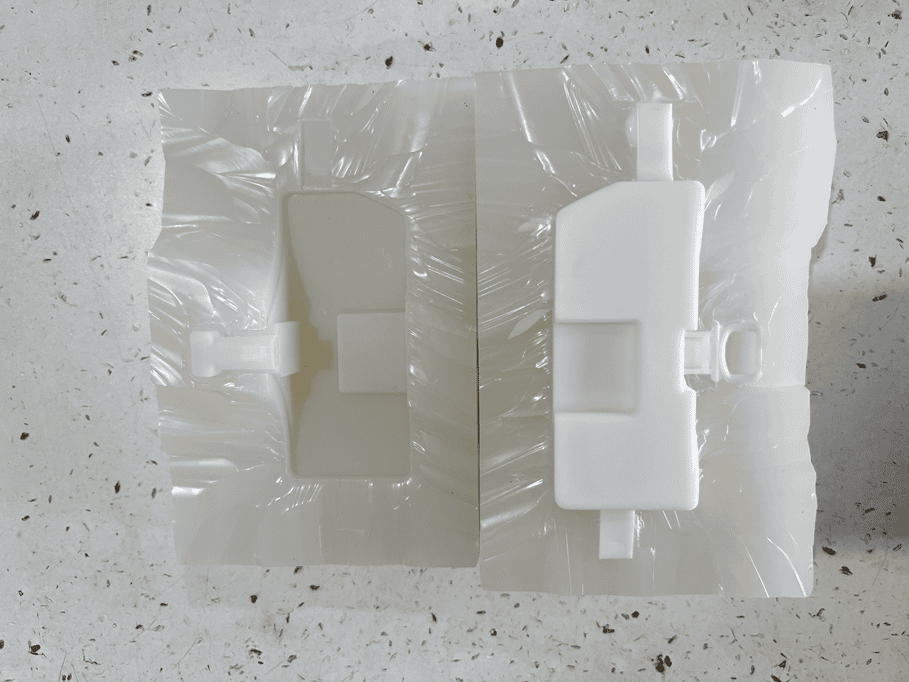

Stage 2. Silicone Mold Production

High-quality liquid silicone (RTV) molds are crafted for durability, minimal shrinkage, and precise detail replication. The mold-making process includes:

- Securing the master in a casting box with plastic rods to define gates and vents.

- Applying a parting line tape for easy mold separation post-curing.

- Vacuum-pouring silicone around the master to eliminate air bubbles, followed by oven curing at 40°C for 8–16 hours.

Stage 3. Urethane Casting Process

Strict protocols ensure consistency and quality:

- Preheat the silicone mold to 60–70°C to optimize resin flow.

- Apply a release agent to prevent adhesion issues.

- Mix and degas two-component polyurethane resin under vacuum (40°C) for 50–60 seconds to eliminate air pockets.

- Pour resin into the mold within a vacuum chamber, then cure in an oven (1–6 hours based on part size).

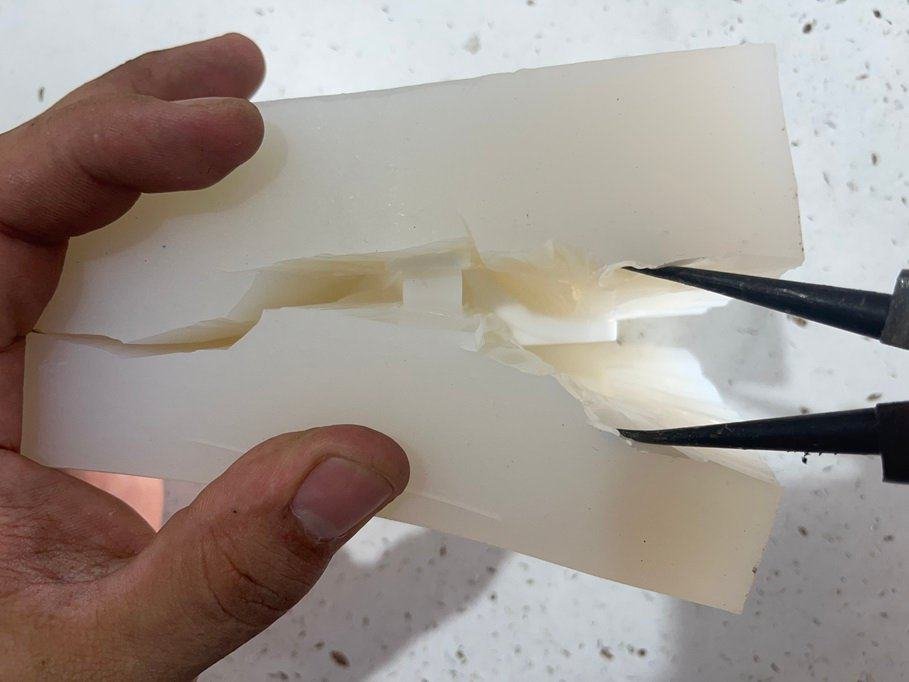

- Demold the finished part, inspect for quality, and reuse the silicone mold for repeated cycles.

Advantages of Vacuum Casting

Cost-Effective Silicone Molds

Urethane casting utilizes affordable silicone molds, eliminating the need for costly metal tooling. This makes it ideal for producing high-quality prototypes and low-volume parts at a fraction of traditional manufacturing expenses.

Rapid Turnaround Times

Deliver up to 50 functional urethane parts within 10–15 days, accelerating product development cycles and meeting tight deadlines for prototyping or small-batch production.

Diverse Material Options

Choose from a wide range of polyurethane resins, including flexible, rigid, impact-resistant, or transparent formulations, tailored to mimic end-use material properties.

High Precision and Detail Replication

Achieve tight tolerances and intricate geometries with production-grade accuracy, ensuring cast parts match design specifications for functional testing or final use.

Superior Surface Finishes

Urethane casting delivers smoother textures and finer aesthetic details compared to CNC machining or 3D printing, reducing post-processing efforts for market-ready models.

Technical Guide for Urethane Casting

Standard Accuracy

Standard tolerance of ±0.15mm/100mm, with precision up to ±0.05mm for critical applications.

Silicone Mold Lifespan

Each mold produces 15–20 high-quality parts. Complex or clear parts may reduce output to 10–12 casts per mold.

Standard Lead Time

Deliver 50 units within 7–10 days, depending on part complexity and batch size.

Surface Finishes & Features

Options include color matching, textures, gloss/matte coatings, inserts, overmolding, and polished transparent finishes.

Maximum Part Dimensions

Accommodates molds up to 1.8m x 1.0m x 0.8m, suitable for large-scale prototypes and functional components.

Minimum Wall Thickness

Optimal wall thickness: 1.5mm–2.5mm. Minimum feasible thickness: 0.6mm for delicate geometries.

Applications of Vacuum Casting

Low-Volume Production / Short-Run Manufacturing

Vacuum casting is ideal for producing high-quality plastic prototypes and end-use parts in small batches (10–500 units). When injection molding is cost-prohibitive for limited quantities, this method delivers production-grade components weeks faster than traditional tooling. Advanced materials like polyurethane resins replicate the properties of ABS, PP, or rubber, enabling functional testing and market validation without upfront mold investments.

Aesthetic Models / Color & Texture Prototyping

Create visually precise models with customizable colors, textures, and finishes using silicone molds. Test multiple design iterations—such as matte, glossy, or metallic surfaces—by casting 10–15 units for internal reviews or client presentations. This process eliminates guesswork in final product aesthetics, ensuring alignment with brand guidelines before mass production.

Engineering Verification / Functional Testing

Vacuum casting supports cost-effective design validation and iterative modifications. Prototypes withstand mechanical stress, thermal exposure, and environmental simulations, providing reliable data for certifications or regulatory approvals. Low-cost tooling allows rapid adjustments, reducing risks before committing to high-volume manufacturing.

Marketing & Display Models

Produce photorealistic, functional models for trade shows, user testing, or digital campaigns. Urethane-cast parts mimic end-product quality, enabling client engagement and pre-launch feedback. Display units can be quickly updated for evolving designs, ensuring marketing materials stay current across brochures, websites, or exhibitions.