Custom Sheet Metal Fabrication Services

Track your project in real-time—from design validation to final shipment. Our focus on user-centric design, meticulous attention to detail, and agile production processes empower innovators worldwide to accelerate market entry.

- Quality Assurance: ISO-certified inspections at every stage.

- On-Time Delivery: 98% adherence to committed deadlines.

- Design Optimization: DFM feedback to reduce costs and enhance manufacturability.

Custom Sheet Metal Fabrication Services | Rapid Prototyping and Volume Production

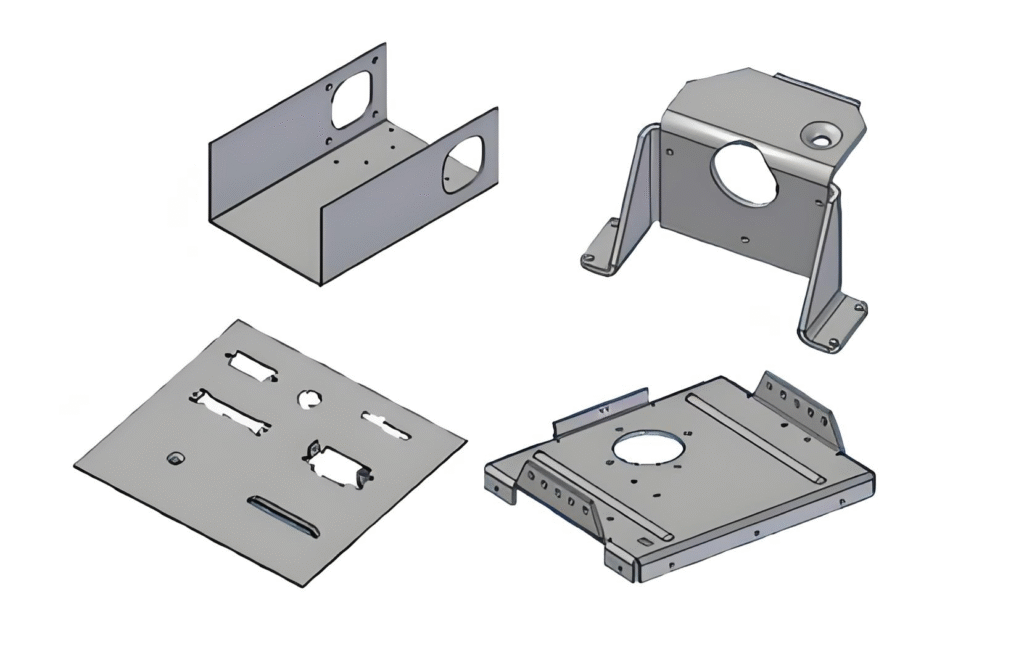

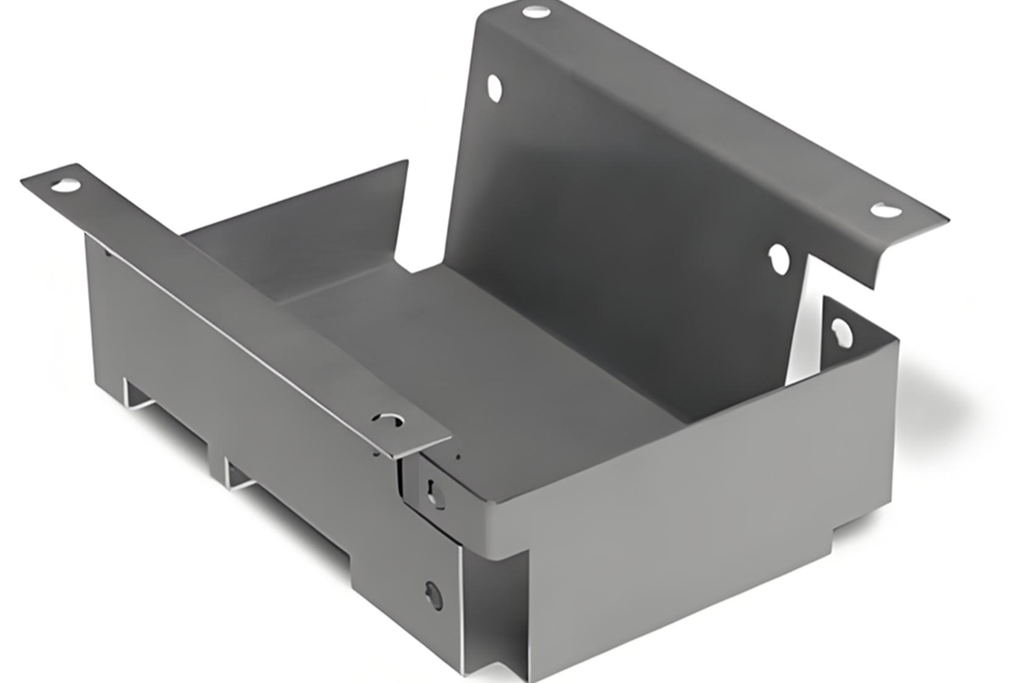

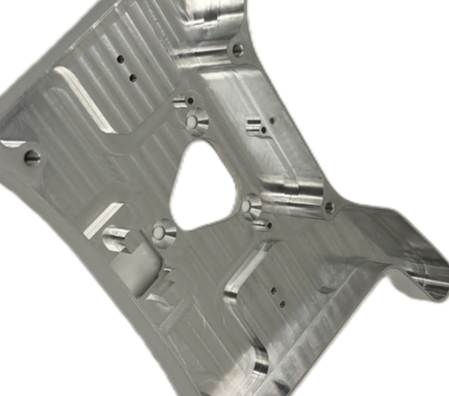

At Samshion, we specialize in precision sheet metal fabrication, transforming standard-gauge metals into durable prototypes and end-use components—from single-unit batches to high-volume orders. Combining advanced bending, punching, and cutting technologies with unmatched material expertise, we deliver parts that meet stringent functional and aesthetic demands across industries.

- Material Versatility: Work with stainless steel, aluminum, copper, and specialty alloys.

- End-to-End Solutions: Prototyping, surface treatment (anodizing, powder coating, plating), and assembly.

- Speed & Precision: Tight tolerances (±0.1mm) and rapid lead times, from 5 days for prototypes.

- Scalability: Seamlessly transition from 10 to 10,000+ units without compromising quality.

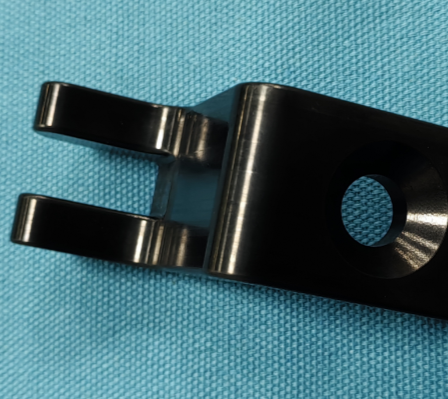

Sheet Metal Fabrication Services for Custom Parts

We have advanced machines, including laser cutters, bending systems, and welding equipment, we deliver precision sheet metal components tailored to your needs—from prototype batches to large-scale production. Our skilled engineering team ensure rapid turnaround times without compromising quality, supporting industries globally with reliable and efficient manufacturing solutions.

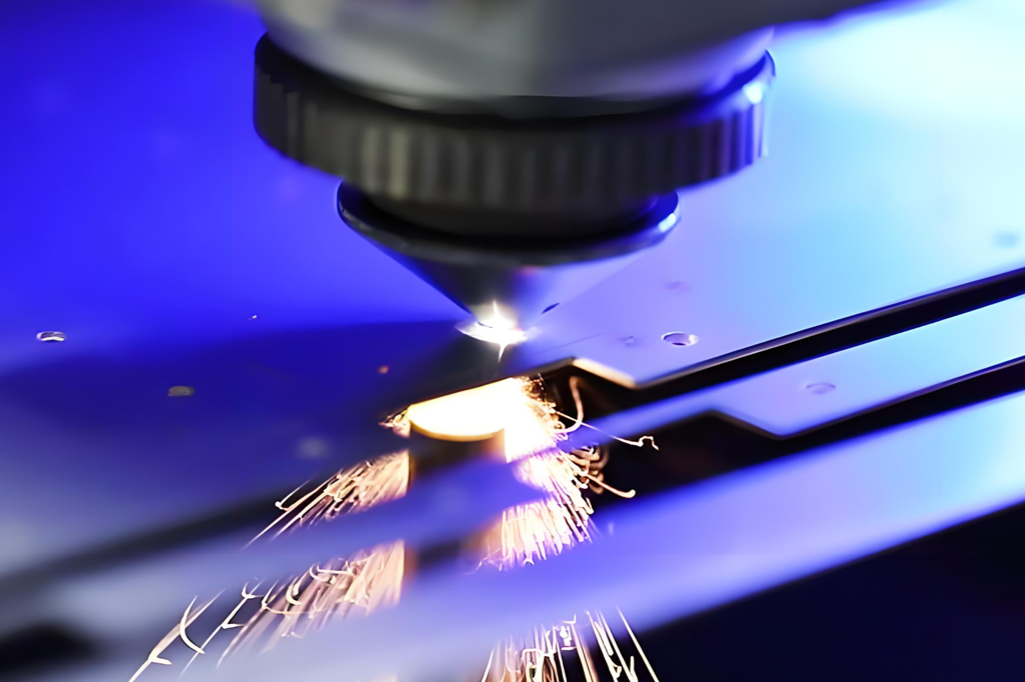

Laser Cutting

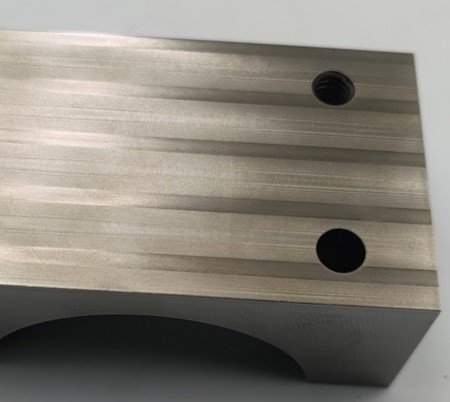

Laser cutting employs a high-intensity beam to precisely cut, etch, or engrave materials, achieving intricate patterns and smooth edges as per design specifications. This method is ideal for complex geometries and tight tolerances, making it a top choice for industries requiring detailed and durable metal components.

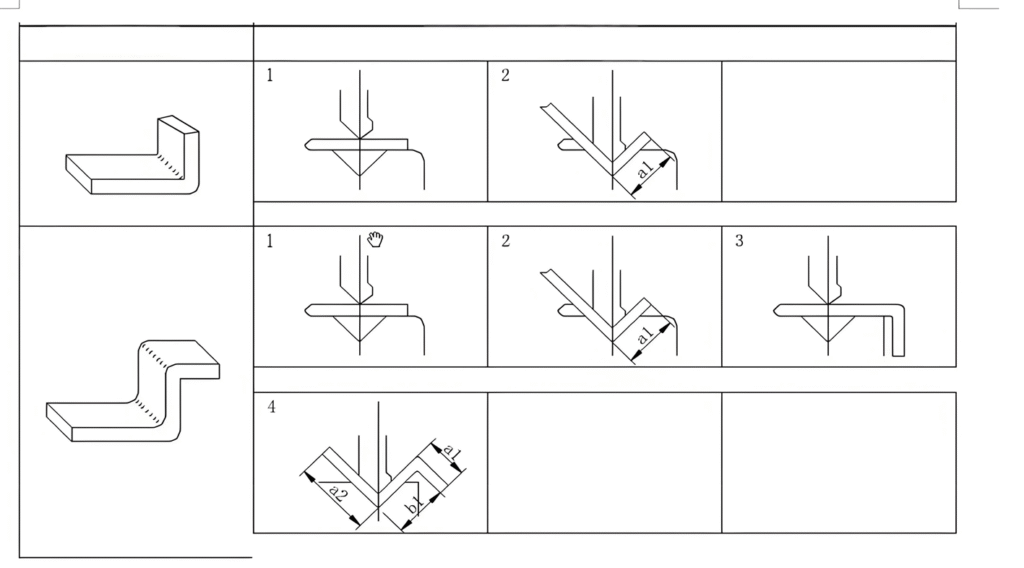

Bending

Bending reshapes thin metal sheets into desired forms such as U-channels, V-angles, or custom profiles using controlled force. Capable of handling varying material thicknesses, this process ensures consistent results for both structural and aesthetic applications.

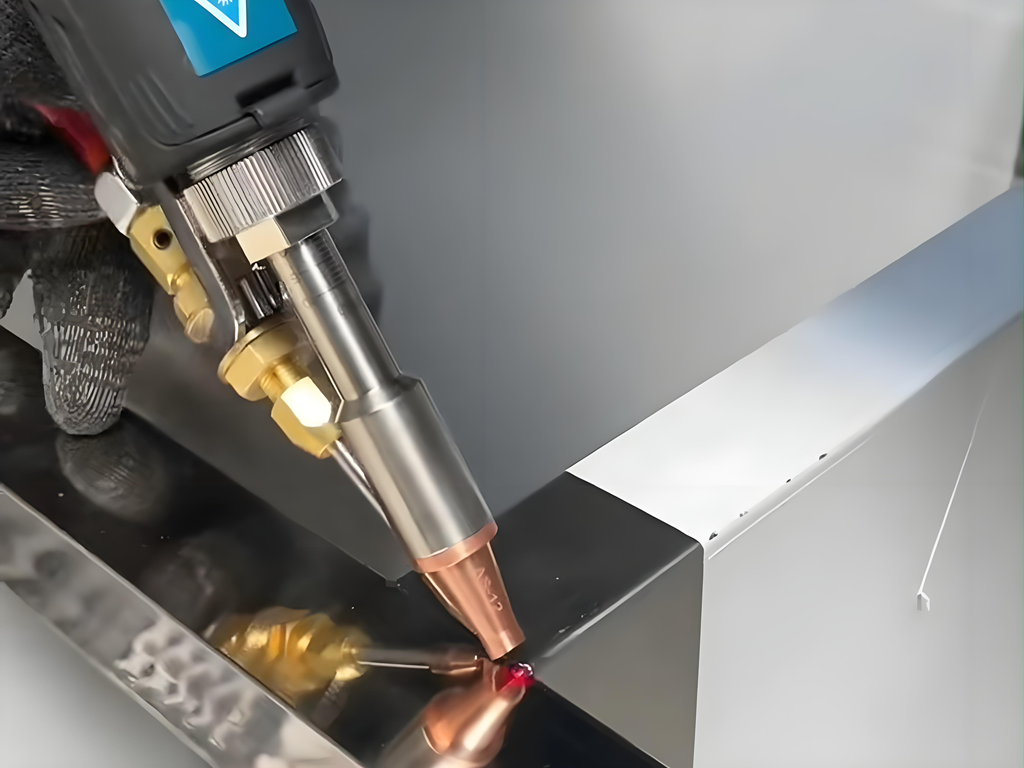

Welding

Welding combines heat and pressure to fuse metal pieces into robust, long-lasting assemblies. Our expertise in MIG, TIG, and spot welding techniques guarantees strong, seamless joints for critical applications across automotive, aerospace, and industrial sectors.

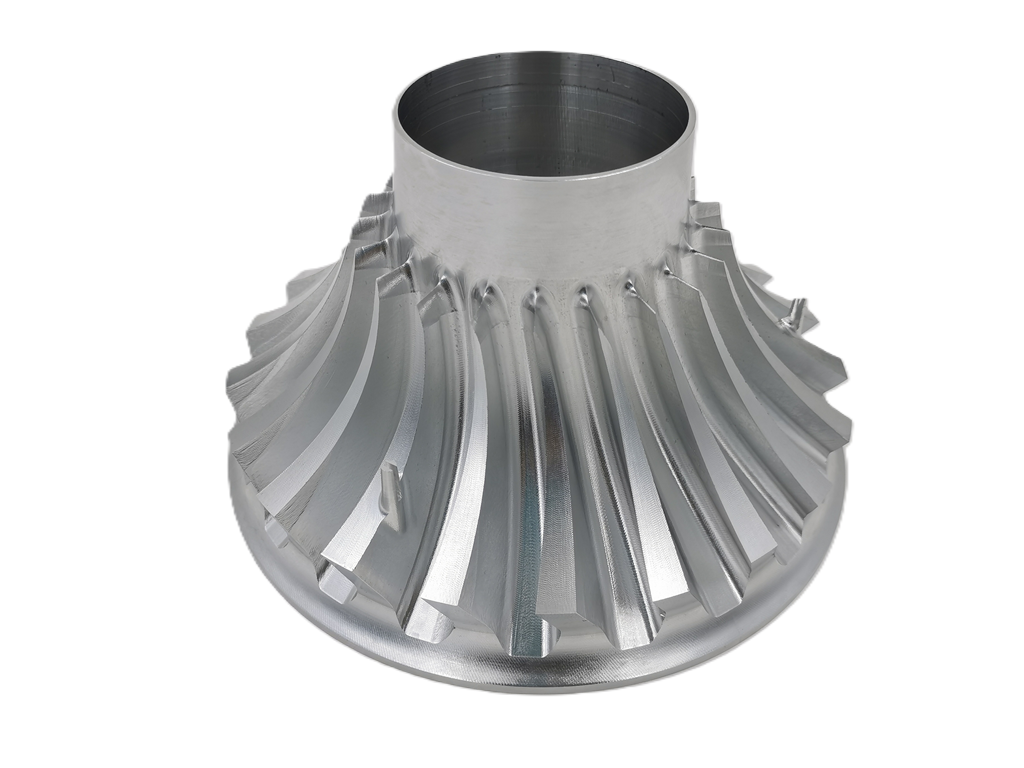

What Is Sheet Metal Fabrication?

Sheet metal fabrication is a precision-driven manufacturing process that transforms flat metal sheets into functional components through cutting, bending, punching, and assembly. By utilizing techniques like laser cutting, press braking, and welding, thin metal sheets are shaped into complex geometries with high accuracy and durability. These parts are widely used in end-use applications such as enclosures, brackets, and structural frameworks, offering engineers reliable solutions for industrial, automotive, and electronic systems.

If you require custom sheet metal fabrication or seek a trusted partner for outsourcing precision metal parts, Samshion delivers expertise and efficiency. Connect with our skilled engineers and technicians to explore cost-effective, high-quality solutions tailored to your project’s specifications—whether for prototypes or large-scale production.

How Does Sheet Metal Fabrication Work?

Sheet metal fabrication begins by shaping thin metal sheets through subtractive processes, where material is removed using cutting tools guided by programmed patterns. Techniques like laser cutting, waterjet, or CNC punching create precise features such as holes, slots, or complex contours based on the part design. Once cut, the metal undergoes deformation—commonly through press brakes—to bend or form it into 3D geometries like angles, channels, or enclosures. The final stage involves assembling fabricated pieces, often combining sheet metal with other components, to construct a complete product. Surface treatments like powder coating or anodizing may follow to enhance durability, aesthetics, or resistance to environmental factors.

For reliable sheet metal fabrication services, partner with Samshion to transform designs into precision-engineered components. Our expertise spans prototyping to high-volume production, ensuring quality and efficiency at every stage.

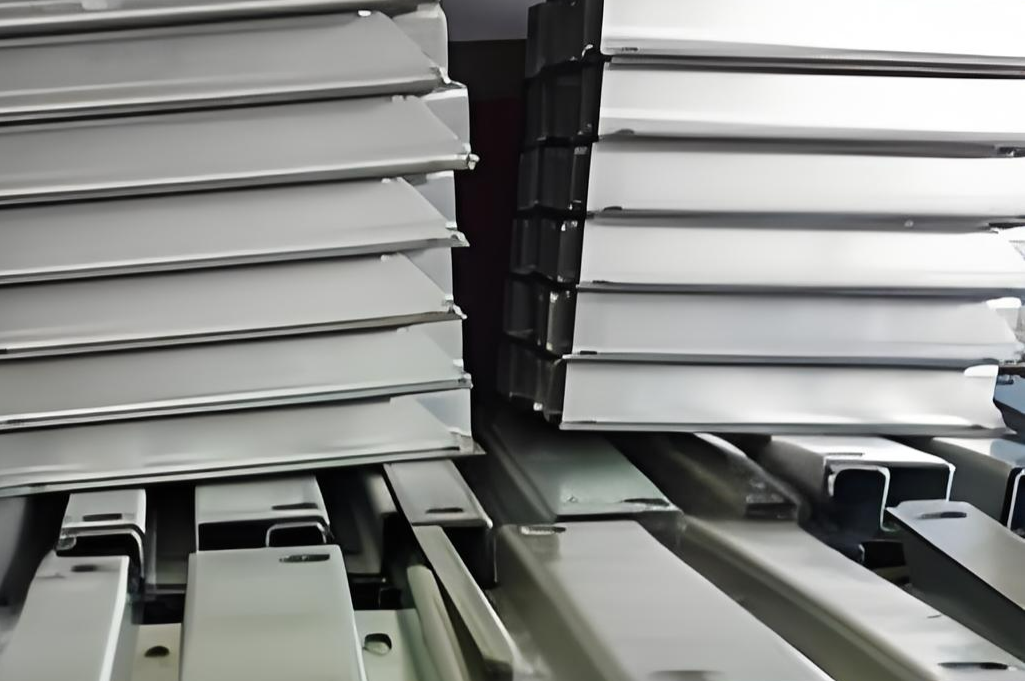

Sheet Metal Prototyping to Production

Rapid sheet metal prototyping services at Samshion empower you to develop functional prototypes and validate designs through rigorous testing before market launch, minimizing development costs and risks. Our seamless transition from prototyping to full-scale production ensures precision, durability, and compliance with your specifications, making us the ideal partner for end-to-end sheet metal fabrication.

By collaborating with our team, you gain access to advanced CNC machining, precision tooling, and scalable solutions tailored to your project’s needs—whether for initial concept validation or high-volume manufacturing.

Rapid Prototyping

Obtain precision sheet metal prototypes in as few as 3 business days, with no minimum order requirements. This service accelerates design validation, reduces iteration costs, and ensures functional testing for faster product development.

- Lead Time: 1-5 business days

- Volume: 1-100 units

- Real-time DFM feedback for design optimization.

Low-Volume Manufacturing

Bridge prototyping and mass production with flexible, small-batch manufacturing. Ideal for market testing or phased rollouts, our service guarantees consistent quality and on-time delivery for mid-sized orders.

- Lead Time: 5-15 business days

- Volume: 101-10,000 units

- Achieve ±0.1 mm tolerances for tight specifications.

High-Volume Manufacturing

Scale seamlessly with large-scale sheet metal fabrication, including finishing and assembly. Our advanced facilities deliver high precision, cost efficiency, and strict adherence to specifications for bulk orders.

- Lead Time: 2-4 weeks

- Volume: 10,001+ units

- 30% Cost Reduction via robotic automation and bulk pricing.

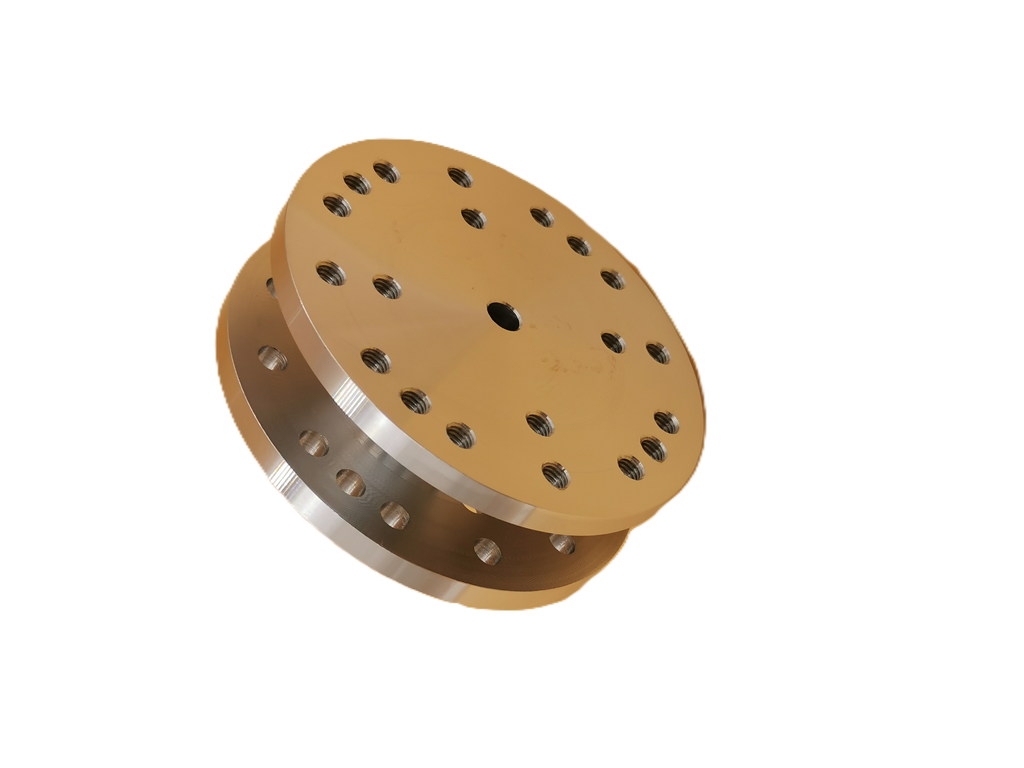

Sheet Metal Materials Available at Samshion

A wide variety of materials are utilized in sheet metal fabrication to meet diverse industrial needs. Aluminum stands as a top choice due to its lightweight and corrosion resistance, with popular grades including 3003-H14 (excellent formability), 5052-H32 (high strength), 6061-T6 (structural applications), and 1100-H14 (general-purpose use). Stainless steel grade 304 is widely favored for its superior weldability, formability, and rust resistance, ideal for food processing or architectural components. For harsher environments like marine or chemical industries, grade 316 stainless steel offers enhanced corrosion protection. Brass, known for its conductivity and aesthetic appeal, is optimal for electrical components and decorative parts requiring precision forming and durability.

At Samshion, we source premium materials to ensure your sheet metal projects achieve functional and aesthetic excellence, whether for prototypes or high-volume production.

Aluminum

Aluminum alloys are engineered metallic materials composed primarily of aluminum combined with elements such as copper, magnesium, silicon, or zinc. Renowned for their exceptional strength-to-weight ratio, corrosion resistance, and versatility, aluminum alloys are widely used across industries ranging from aerospace to consumer electronics.

Alloys: 5083,5052.etc.

Finishing Options: Alodine, Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing.

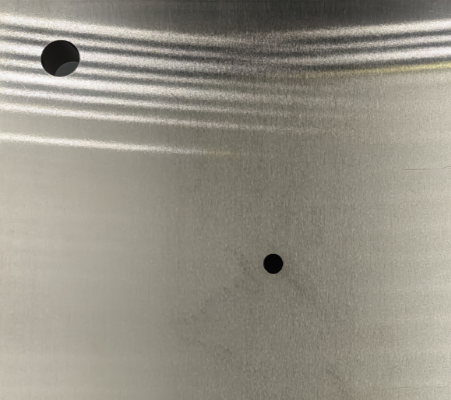

Stainless Steel

Stainless steel is a corrosion-resistant iron-based alloy containing a minimum of 10.5% chromium, combined with elements like nickel, molybdenum, and carbon. Renowned for its durability, aesthetic versatility, and hygienic properties, stainless steel is a cornerstone material in industries ranging from medical devices to architectural design.

Alloys: 303, 304L, 316L, 410, 416, 440C, 17-4PH, Nitronic 60.etc.

Finishing Options: Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Black Oxide, Zinc Plating, Vibratory Tumbling.

Steel

Steel, an iron-carbon alloy enhanced with controlled amounts of other elements, is the backbone of modern engineering and construction. Renowned for its unparalleled strength, versatility, and cost-effectiveness, steel is pivotal across industries from infrastructure to advanced manufacturing.

Carbon Steel Types: 1045 Carbon, 1018 Carbon, Galvanized Low-Carbon.etc.

Alloys: 4140, 430, 420, 4130.etc.

Finishing Options: Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Black Oxide, Zinc Plating, Vibratory Tumbling.

Copper

Copper, a ductile and malleable metal with exceptional electrical and thermal conductivity, is a cornerstone of modern technology and industrial applications. Known for its natural reddish-brown hue, corrosion resistance, and recyclability, copper and its alloys are indispensable in sectors ranging from electronics to renewable energy.

Brass: H59,H62.etc.

Copper: C1100,C1011.etc.

Finishing Options: Media Blasting, Nickel Plating, Passivation, Tumble Polishing, Vibratory Tumbling.etc.

Surface Finishing Options for Metal Sheets

Surface treatments play a critical role in enhancing the mechanical performance, chemical resistance, and visual appeal of sheet metal components. By applying specialized finishes, you can extend the lifespan of parts, improve functionality in harsh environments, and achieve a polished aesthetic tailored to your application. Below are key finishing options compatible with sheet metal fabrication processes, designed to meet industrial and commercial standards.

For tailored solutions, partner with Samshion to select the ideal finish for your project—whether prioritizing durability, aesthetics, or compliance with regulatory requirements.

As Machined

The as-machined finish delivers parts directly from CNC machining, retaining minor tool marks for a cost-effective solution. Ideal for functional prototypes and non-critical components requiring no post-processing.

Anodizing

Anodizing enhances corrosion resistance, wear resistance, and aesthetics for aluminum parts. Custom colors and glossy finishes available.

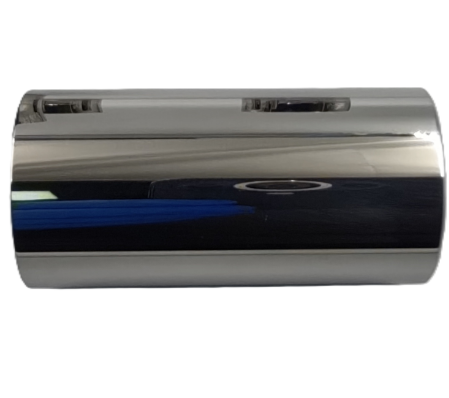

Polishing

Achieve a mirror-like finish with polishing, reducing surface roughness to Ra 0.2 µm. Perfect for luxury products and optical components.

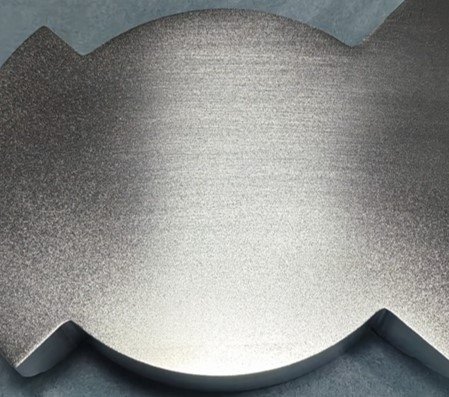

Sand Blasting

Sand blasting creates a uniform matte texture, hiding imperfections and improving paint adhesion. Uses pressurized media for consistent results.

Tumbling

Tumbling smooths edges and surfaces via friction in a rotating barrel, offering a slightly textured, uniform finish for small parts.

Electropolishing

Electropolishing chemically removes surface layers to enhance smoothness, brightness, and corrosion resistance. Ideal for stainless steel and medical devices.

Alodine

Alodine coating provides corrosion protection and paint adhesion for aluminum, with a conductive yellow film.

Heat Treatment

Heat treatment enhances metal properties like hardness, strength, or ductility in a controlled vacuum environment.

Brushed Finish

A brushed finish creates a unidirectional satin texture, masking scratches and adding aesthetic appeal.

Powder Coating

Powder coating applies a thick, wear-resistant polymer layer with vibrant color options and UV resistance.

Nickel Electroplating

Electroplating deposits a thin nickel layer for enhanced wear resistance, conductivity, and corrosion protection.

Black Oxide Coating

Black oxide forms a magnetite layer on ferrous metals, reducing glare and improving corrosion resistance.

Uncompromising Quality Assurance

At the heart of Samshion’s operations lies an uncompromising quality philosophy. Advanced spectroscopy verifies every material batch, while 3D scanning systems validate dimensional compliance to micrometer-level precision. Monthly process audits and a 99.2% first-article acceptance rate reflect our dedication to continuous improvement. This disciplined approach has fostered long-term partnerships, with 40% of clients returning for repeat projects over five consecutive years—a testament to our ability to balance speed, precision, and reliability.

Advanced Inspection Technology

We deploy cutting-edge equipment to guarantee unmatched precision:

- CMM & 3D Scanners: For micron-level dimensional accuracy.

- XRF Analyzers: Verify material composition and RoHS compliance.

- Optical Comparators & Micrometers: Ensure surface finish and critical tolerances.

- Automated Gauging Systems: Real-time monitoring for consistency.

End-to-End Quality Control

Our ISO 9001:2015 certified team enforces rigorous checks at every stage:

- Pre-Production: DFM analysis and material certification.

- In-Process: Statistical process control (SPC) and on-site inspections.

- Final Audit: Functional testing, visual inspections, and performance validation.

- Documentation: Detailed reports including FAIs, PPAP, and compliance certificates.

Trusted by Global Industries

With 20+ years of expertise, Samshion delivers:

- Zero-Defect Guarantee: Rooted in Six Sigma methodologies.

- Fast Turnarounds: Prototypes in 3 days, production batches in 7 days.

- Full Traceability: Material certs, inspection logs, and compliance documentation.

Sheet Metal Fabrication For Various Industries

Sheet metal fabrication is a versatile and cost-effective manufacturing method that serves diverse industries, from prototyping to high-volume production. Its adaptability makes it ideal for creating precision components such as enclosures, brackets, panels, and structural frameworks. Common applications span automotive systems (e.g., chassis, exhaust components), electronics (e.g., server racks, device housings), HVAC ductwork, aerospace assemblies, and medical equipment (e.g., surgical tools, imaging devices).

This process also supports custom solutions for architectural elements (e.g., signage, decorative facades), industrial machinery (e.g., conveyor systems, guards), and consumer goods (e.g., appliances, lighting fixtures). Whether for low-volume prototypes or mass production, sheet metal fabrication ensures durability, dimensional accuracy, and scalability across projects of any complexity.