Aerospace Prototyping And Manufacturing

Access premium manufacturing services for custom aerospace prototypes and flight-certified components. Accelerate product launches, mitigate risks, and streamline compliance with on-demand production at competitive pricing.

- High-Precision Tolerances (±0.0005")

- ISO 9001:2015 Certified

- 24/7 Technical Support

What Aerospace Components Can We Manufacture for You?

The aerospace industry demands ultra-precision components crafted from advanced materials, ensuring extreme durability, safety, and compliance with rigorous aviation standards. Our expertise spans commercial aircraft, defense systems, and space exploration technologies. Key requirements we address include:

- Quality control via CMM, GD&T, and NDT validation

- Lightweight, high-strength materials for fuel efficiency and thermal resistance

- Micron-level tolerances (±0.005mm) for mission-critical flight systems

Our cutting-edge manufacturing capabilities empower us to deliver solutions for aerospace applications:

- Prototypes and R&D models for concept validation

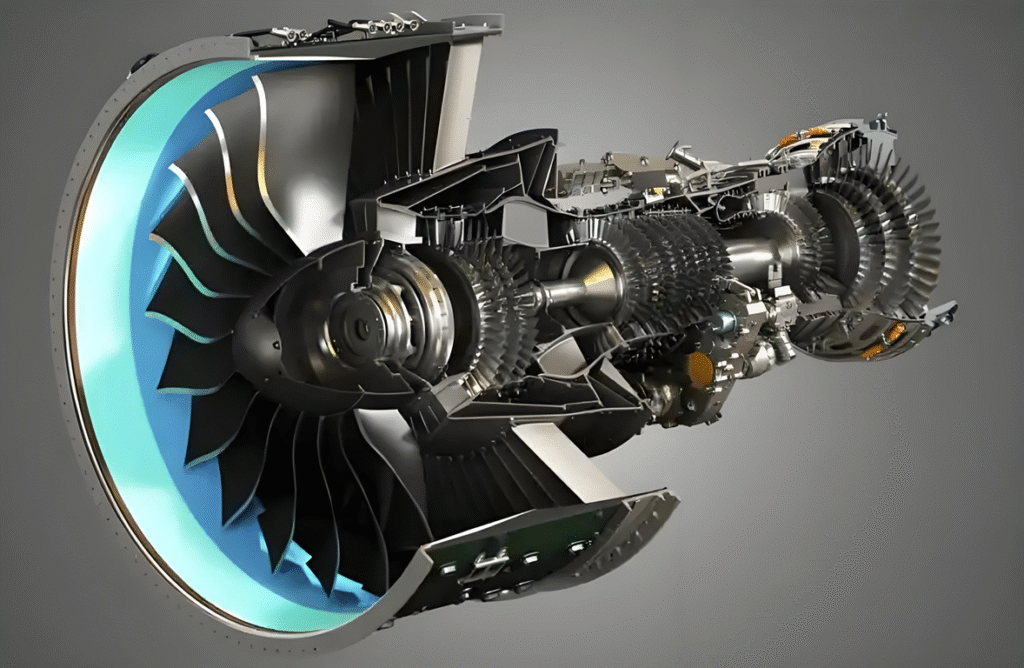

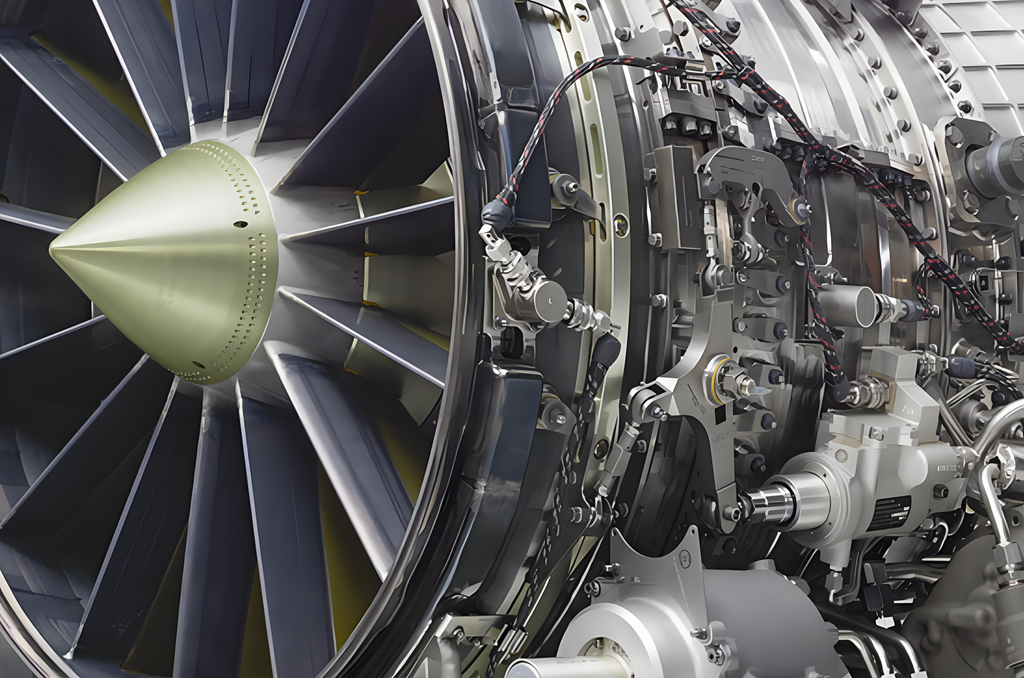

- Turbine blades and jet engine components (combustors, fan disks)

- Structural airframe parts (bulkheads, wing ribs, fuselage panels)

- Avionics housings and satellite communication modules

- Landing gear components (actuators, struts, bearings)

- Fuel system assemblies (valves, pumps, manifolds)

- Thermal protection systems (heat shields, cooling ducts)

- Spacecraft propulsion components (thrust chambers, nozzles)

- Interior cabin fittings (seat tracks, overhead bins, lavatory systems)

- Radar and sensor enclosures for defense applications

- Lightweight composite panels (carbon fiber, honeycomb structures)

- Hydraulic and pneumatic system parts

- UAV/drone frames and propulsion units

- Rocket engine components (turbopumps, injector plates)

- High-temperature alloy fasteners and brackets

- Electrical harnesses and connectors for extreme environments

- Custom tooling for MRO (Maintenance, Repair, Overhaul)

Accelerate Your Aerospace Innovation

From Prototyping to Scalable Production

Prototyping

Develop high-performance aerospace prototypes with advanced materials to fast-track design verification. Our team evaluates your 3D models to optimize structural integrity, material compatibility, and manufacturability, ensuring prototypes meet rigorous performance and safety thresholds.

- Rapid iteration for aerodynamic and functional validation

- Complex geometries with ±0.03mm tolerances

- Functional prototypes mirroring final component specifications

Design Compliance And Performance Testing

Validate aerodynamics, structural loads, and operational efficiency using flight-ready prototypes. Refine designs for manufacturability and cost-effectiveness while adhering to global aviation standards.

- CFD (Computational Fluid Dynamics) and FEA (Finite Element Analysis) feedback

- Surface treatments (anodized, thermal-sprayed, polished)

- Assembly fitment and vibration resistance validation

Engineering Certification And Validation

Enhance prototypes through extreme-condition testing, including thermal cycling, fatigue analysis, and electromagnetic interference (EMI) checks. Certify durability and compliance for critical systems like propulsion, avionics, and satellite payloads.

- Load testing for wing assemblies and fuselage structures

- Material validation for cryogenic and high-stress environments

- Acoustic and vibration analysis for cabin systems

Production Validation And Scalability

Validate manufacturing processes with pilot batches. Optimize CNC, additive manufacturing, or composite molding workflows for seamless scalability.

- Prototype tooling for injection molds and autoclave curing

- DFM (Design for Manufacturing) and DFA (Design for Assembly) reviews

- Quality audits for dimensional accuracy and material traceability

Mass Production

Scale to mass production with precision CNC machining, automated composite layup, and end-to-end traceability. Deliver components compliant with AS9100 and FAA regulations for reliability and safety.

- High-speed 5-axis machining (±0.015mm tolerances)

- Robotic composite curing and automated fastener installation

- Full traceability logs and material certifications

ready with your project?

Custom Aerospace Components Manufacturing Solutions

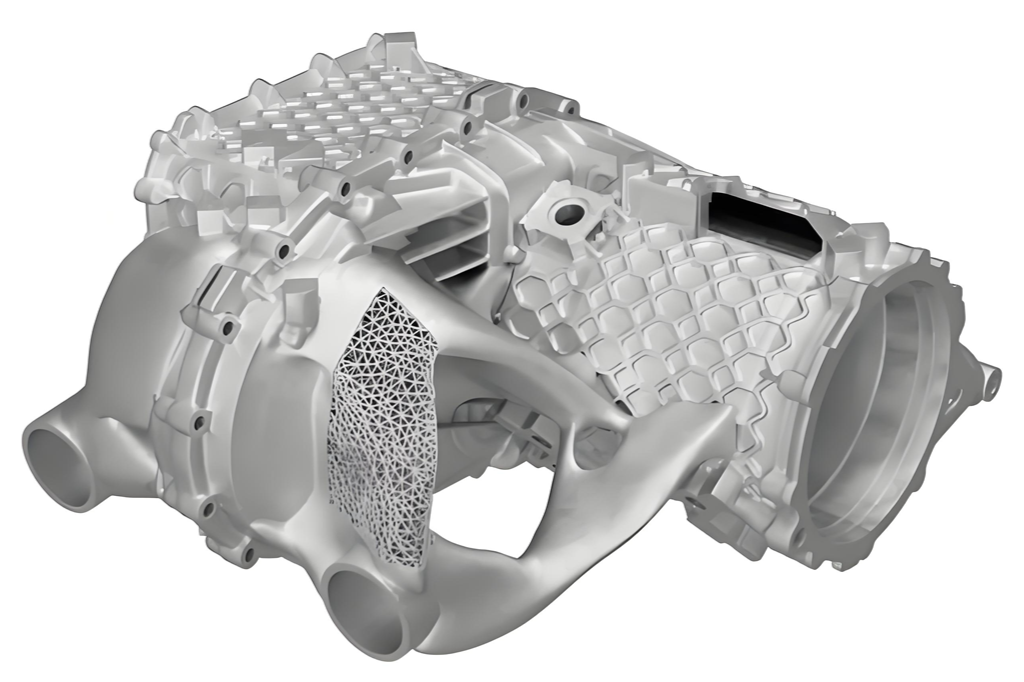

With decades of expertise in aerospace engineering and a proven legacy of delivering mission-critical projects, we specialize in tailored solutions for the most demanding industry requirements. Each methodology is rooted in unique aerospace-grade processes—while technologies may share surface similarities, their implementation, design rigor, and mission-specific goals are precision-engineered. Below are our aerospace manufacturing strategies, designed to harmonize accuracy, scalability, and cost-efficiency for commercial aviation, defense systems, and satellite technologies.

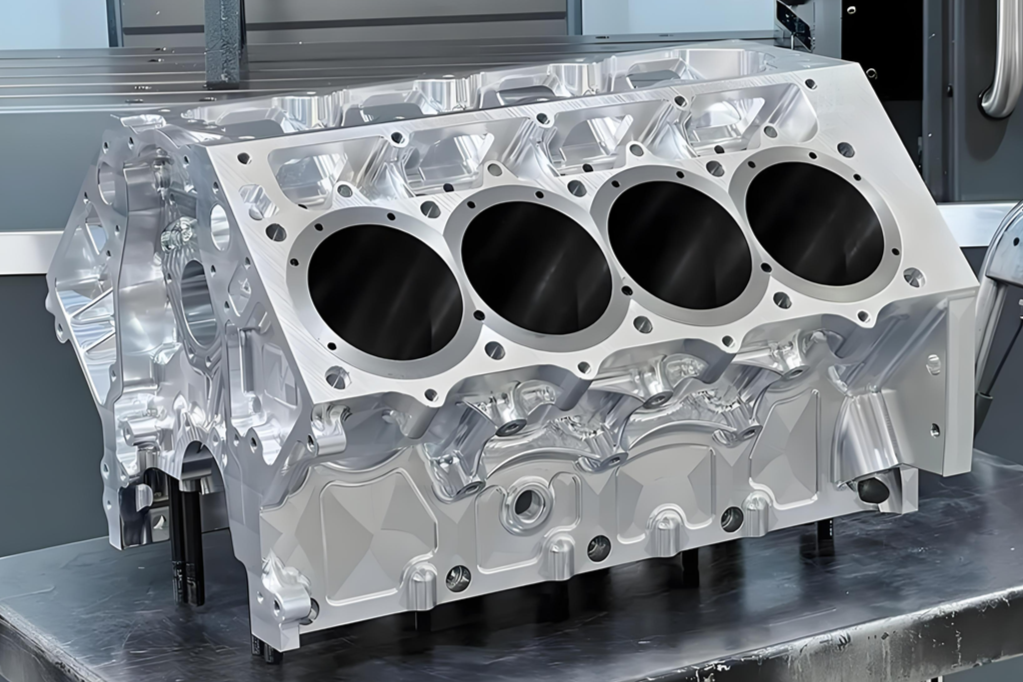

CNC Machining

Produce flight-critical components with multi-axis machining, ideal for turbine disks, landing gear parts, and structural fittings requiring micron-level precision.

Injection Molding

Craft lightweight, high-strength structures using automated fiber placement (AFP) and resin transfer molding (RTM) for wings, fuselage panels, and radomes.

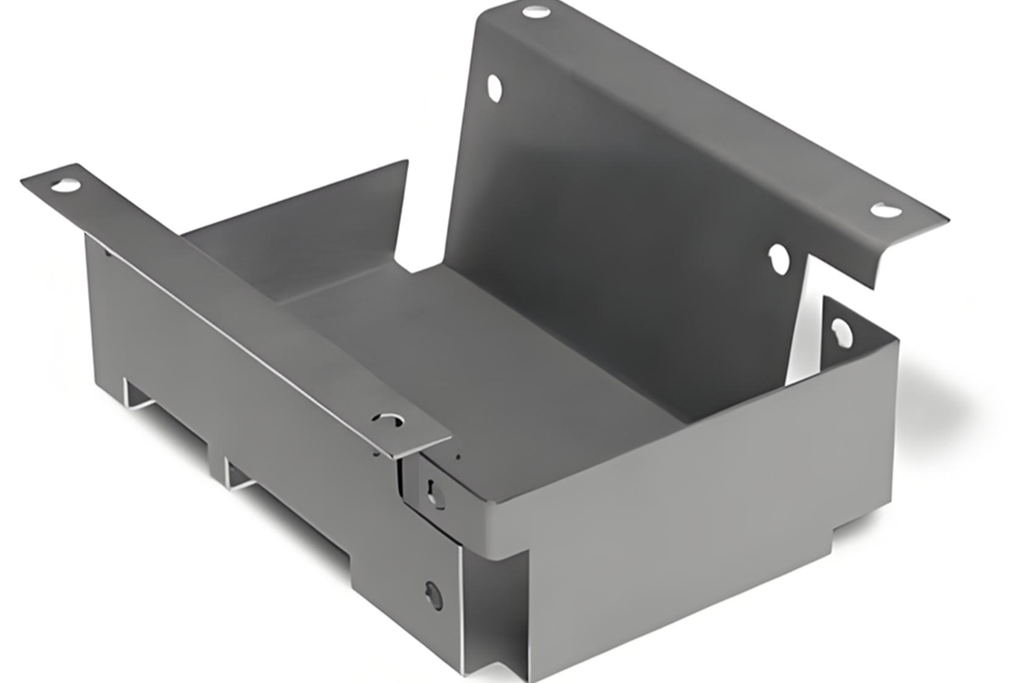

Sheet Metal Fabrication

Rapidly prototype or produce complex geometries like fuel nozzles, heat exchangers, and drone components using aerospace-grade alloys and high-temperature polymers.

3D Printing

Form corrosion-resistant alloys into aerodynamic fairings, brackets, and engine nacelles with tolerances up to ±0.05mm.