Automotive Prototyping And Manufacturing

Access premium manufacturing services for custom automotive prototypes and production parts. Accelerate product launches, mitigate risks, and optimize workflows with on-demand production at competitive pricing.

- Production-Ready Components

- ISO 9001:2015 Certified

- 24/7 Technical Support

What Automotive Components Can We Manufacture for You?

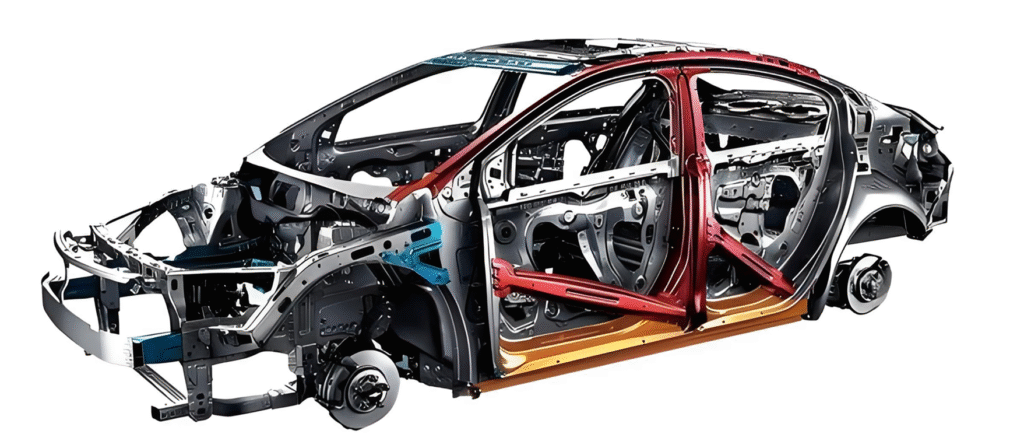

The automotive industry demands precision-engineered parts crafted from high-performance materials, ensuring durability, safety, and compliance with rigorous industry standards. Our expertise spans components for passenger vehicles, commercial fleets, and electric mobility systems. Key requirements we address include:

- ISO 9001 certified quality control via CMM and GD&T validation

- Lightweight, corrosion-resistant materials for fuel efficiency and longevity

- Tight tolerances (±0.01mm) for critical engine, transmission, and chassis assemblies

Our advanced manufacturing capabilities empower us to deliver solutions for diverse automotive applications:

- Prototypes and R&D models for concept validation

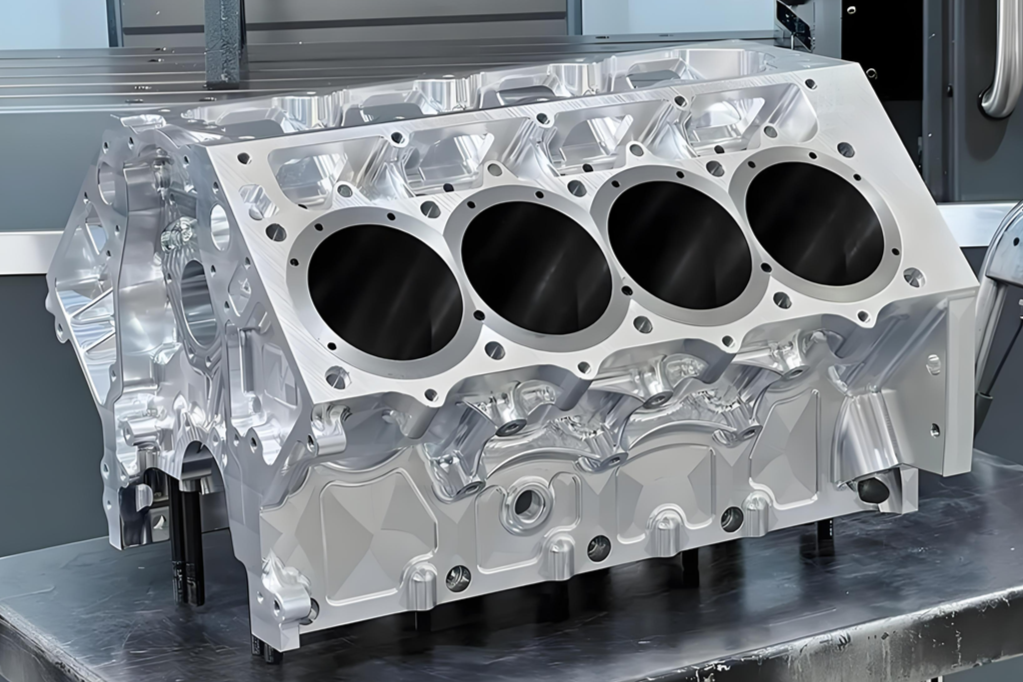

- Engine components (pistons, cylinder heads, turbochargers)

- Transmission systems (gears, shafts, housings)

- Electric vehicle (EV) battery enclosures and cooling systems

- Suspension and braking components (control arms, calipers, rotors)

- Interior and exterior trim (dashboards, grilles, door panels)

- Sensor housings and ADAS (Advanced Driver Assistance Systems) modules

- Fuel system parts (injectors, pumps, manifolds)

- Lighting assemblies (LED modules, reflectors, bezels)

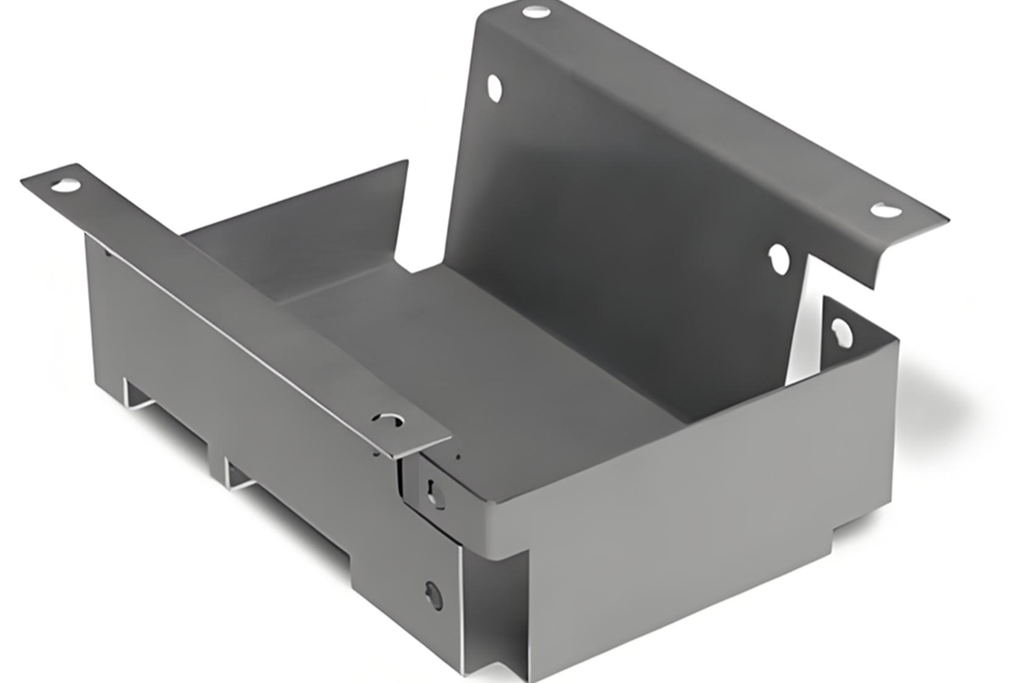

- Custom fasteners and brackets for structural integrity

- Thermal management systems (heat sinks, cooling plates)

- Lightweight alloy wheels and hub components

- EV charging port assemblies and connectors

- Underbody shields and aerodynamic components

- Powertrain mounts and vibration-damping solutions

- High-voltage electrical connectors and harnesses

- Aftermarket performance and tuning parts

Accelerate Your Automotive Journey

From Prototyping to Scalable Production

Prototypes

Develop precision automotive prototypes using production-grade materials to accelerate design validation. Our engineers analyze your CAD files to optimize geometry, material selection, and manufacturability, ensuring prototypes meet performance and aesthetic benchmarks.

- Rapid design iterations for form and function

- Complex geometries with ±0.05mm tolerances

- Functional models replicating final part specifications

Engineering Validation And Testing

Refine prototypes through rigorous performance testing under real-world conditions. Validate durability, thermal resistance, and safety compliance for critical systems like engines, transmissions, and EV battery packs.

- Stress testing for chassis and suspension components

- Material validation for high-temperature alloys and composites

- NVH (Noise, Vibration, Harshness) analysis

Design Validation And Market Testing

Test aesthetics, ergonomics, and user experience with market-ready prototypes. Optimize designs for manufacturability and cost-efficiency while ensuring compliance with automotive standards

- Aerodynamic and crash simulation feedback

- Surface finishes (polished, coated, textured)

- Assembly fitment and ergonomic validation

Production Validation And Scalability

Validate manufacturing workflows with low-volume batches. Optimize CNC machining, stamping, or casting processes for seamless scalability.

- Pilot runs for stamping dies and injection molds

- DFM (Design for Manufacturing) optimization

- Quality audits for dimensional and material consistency

Mass Production

Scale to high-volume manufacturing with precision machining, automated assembly, and end-to-end traceability. Deliver components that meet global automotive standards for performance and safety.

- High-volume CNC machining (±0.01mm tolerances)

- Automated welding and robotic assembly lines

- Full batch documentation and quality certifications

Ready with your project?

Tailored Automotive Parts Manufacturing Solutions

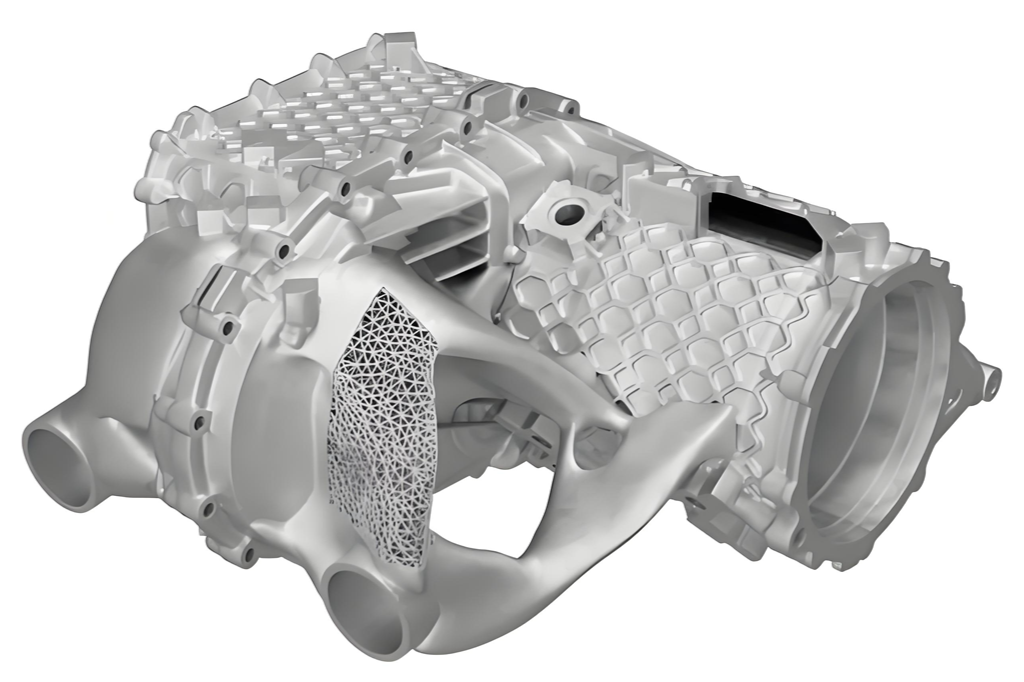

With decades of expertise in automotive component manufacturing and a proven track record of delivering hundreds of successful projects, we have honed specialized solutions to meet diverse industry needs. Each solution is built on distinct manufacturing methodologies—while processes may share similarities in appearance, their workflows, design philosophies, and application-specific objectives are meticulously tailored. Below are our recommended automotive parts manufacturing approaches, engineered to balance precision, scalability, and cost efficiency for passenger vehicles, commercial fleets, and electric mobility systems.

From CNC machining and high-pressure die casting to advanced additive manufacturing, our solutions cater to prototyping, low-volume batches, and mass production. Whether producing engine components, EV battery enclosures, or intricate ADAS modules, we prioritize material integrity, dimensional accuracy (±0.02mm), and compliance with global standards like IATF 16949. Our agile workflows adapt to your project’s lifecycle, ensuring seamless transitions from concept validation to full-scale production.

CNC Machining

Deliver precision-engineered components with advanced milling and turning processes, ideal for complex prototypes and high-performance engine, transmission, or chassis parts.

Injection Molding

Produce durable automotive components at scale using optimized molds, ensuring consistency for interior trim, connectors, and under-the-hood applications.

Sheet Metal Fabrication

Shape lightweight, corrosion-resistant metals into structural brackets, body panels, and EV battery enclosures with tight tolerances (±0.1mm).

3D Printing

Rapidly prototype innovative designs like air ducts, sensor housings, or custom fixtures using automotive-grade polymers and composites.