Rapid Prototyping & Production for Medical Devices Components

Accelerate medical device prototyping and scalable production. From surgical tools to diagnostic equipment.

What Medical Components Can We Manufacture for You?

The healthcare and medical sectors demand precision-engineered parts crafted from specialized materials, ensuring safety, reliability, and compliance with stringent industry standards. Our capabilities span components that interact directly with patients, as well as machinery utilized by medical professionals. Key requirements we address include:

- High-precision tolerances for critical assemblies and devices

- Biocompatible, sterilizable, and non-toxic materials for patient safety

- Comprehensive quality assurance via in-process inspections and CMM validation

Our state-of-the-art manufacturing infrastructure empowers us to refine precision medical equipment production, catering to a wide array of clinical requirements. Notable applications span:

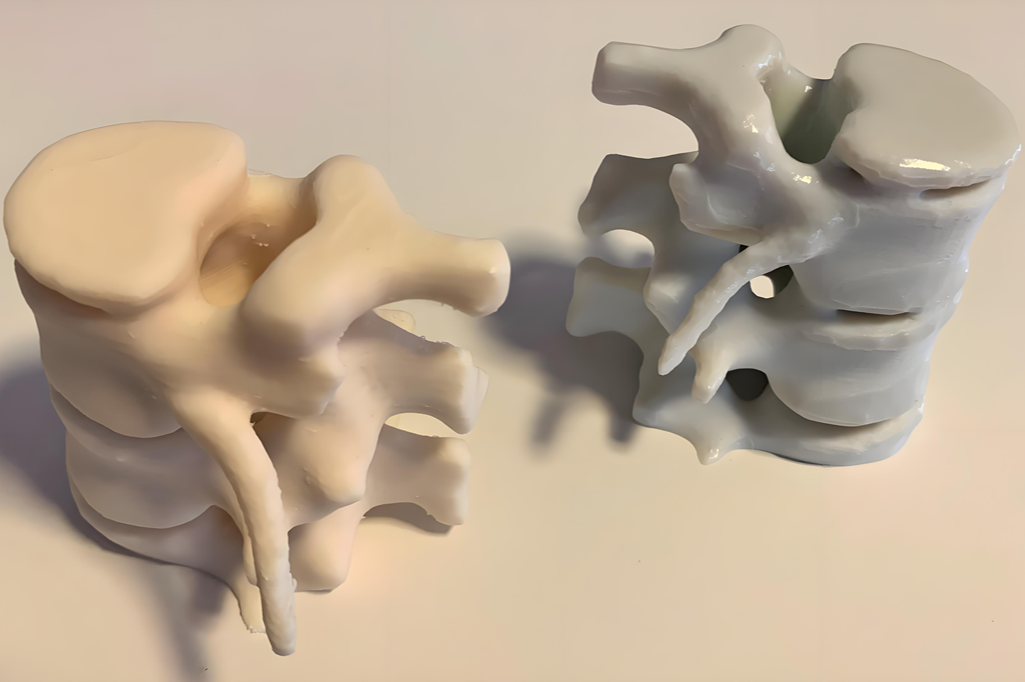

- Prototypes and R&D models

- Patient-specific anatomical replicas

- Surgical tools and instrument replacements

- Imaging system parts (MRI, CT Scan, X-Ray)

- Wearable health monitoring sensors

- Diagnostic equipment housings

- Hospital furniture (beds, tables, panels)

- Mobile medical carts and stations

- Rehabilitation and physiotherapy devices

- Implants and prosthetics

- Drug delivery systems (pumps, injectors)

- Laboratory and biotech consumables

- Respiratory therapy equipment

- Ultrasound and endoscopic components

- Portable diagnostic devices

- Electronic enclosures and connectors

- Disposable medical products

- Patient care accessories

Accelerate Your Medical Device Journey

From Prototyping to Scalable Production

Prototypes

Develop high-precision prototypes using production-grade materials to fast-track your design phase. Our team reviews your design files to suggest optimizations in geometry, material selection, and manufacturability, ensuring prototypes align with functional and aesthetic goals.

- Rapid design and material iterations

- Complex geometries with micron-level accuracy

- Functional models mirroring final product specifications

Engineering Validation And Testing

Refine prototypes through rigorous performance testing and reliability checks. We build functional units that simulate real-world conditions, helping you identify design flaws, material limitations, or ergonomic challenges. Receive actionable insights to enhance product durability and user safety.

- Performance testing under clinical conditions

- Risk mitigation via iterative failure analysis

- Material validation for biocompatibility and sterilization

Design Validation And Market Testing

Validate your product’s functionality, aesthetics, and user experience before launch. Iterate designs efficiently to reduce time-to-market and costs. Deliver polished prototypes with premium finishes for stakeholder feedback and pilot testing.

- Functional and aesthetic performance evaluation

- Ergonomic and usability assessments

- High-quality surface finishes (textured, polished, coated)

Production Validation And Scalability

Prepare for mass production with verified manufacturing workflows and advanced quality controls. Test low-volume batches to optimize tooling, refine processes, and ensure cost-effective scalability.

- Pilot production for process verification

- Rapid tooling for CNC, molding, or 3D printing

- Design-for-manufacturing (DFM) optimization

- Rigorous quality checks and batch consistency

Mass Production

Scale seamlessly to high-volume production of end-use medical components. Leverage precision machining (±0.01mm tolerances), advanced post-processing, and stringent quality protocols to meet global performance standards.

- High-volume CNC machining and injection molding

- Precision finishing (anodizing, laser etching, assembly)

- Sterilization-compatible packaging solutions

- Full traceability and batch documentation

ready with your project?

Our Manufacturing Capabilities

Samshion delivers precision manufacturing solutions tailored for medical devices and equipment. Our state-of-the-art facilities processes ensure compliance with stringent healthcare standards, producing high-quality components for diagnostics, surgical tools, and implantable devices.

CNC Machining

Craft biocompatible, sterilizable components (surgical instruments, orthopedic implants, MRI housing) with micron-level tolerances (±0.02mm) using medical-grade metals like titanium, stainless steel 316L, and cobalt-chromium alloys.

Injection Molding

Produce high-volume medical consumables (syringes, IV connectors, catheter hubs) with FDA-approved polymers (PEEK, PC, PE) and cleanroom-compliant molding processes.

Sheet Metal Fabrication

Form enclosures for diagnostic equipment, surgical trays, and sterilization containers from corrosion-resistant metals, ensuring precision bending and welding for clinical environments.

3D Printing

Prototype patient-specific anatomical models, custom prosthetics, or surgical guides using biocompatible resins, nylon, or sterilizable polymers.