Master Complex Geometries with Precision 5-Axis CNC Machining

Seamlessly produce intricate parts with unmatched accuracy, superior surface finishes, and fast lead times — from prototypes to production.

- Up to ±0.005 mm Tolerances

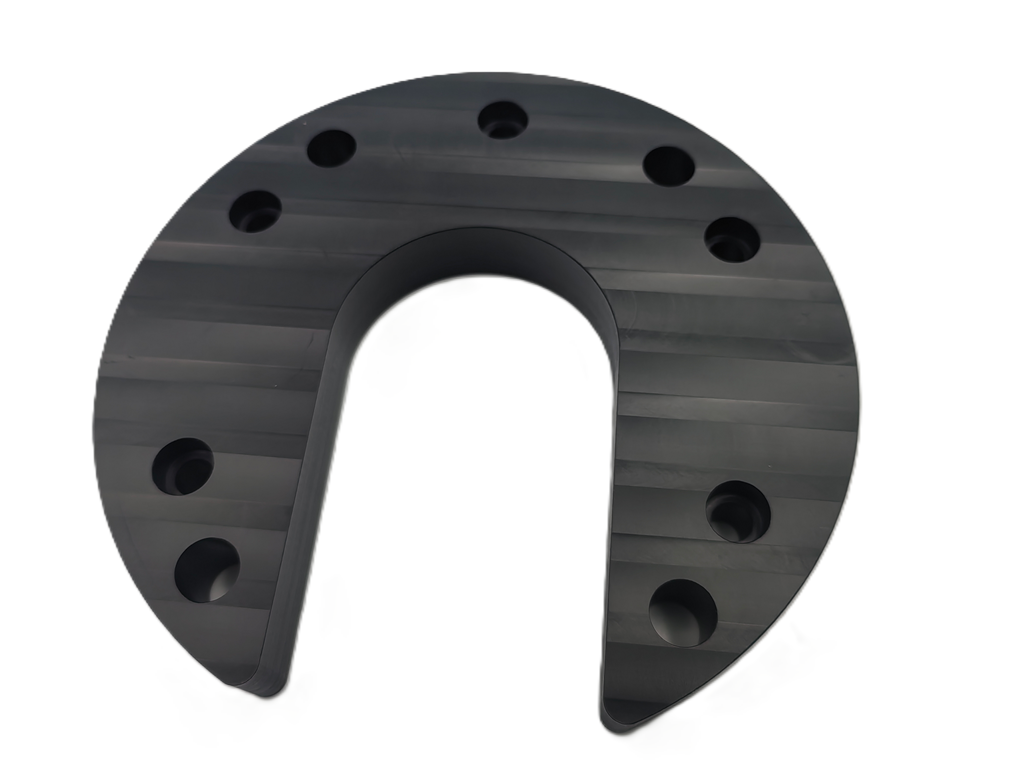

- Complex Contours, Undercuts, Deep Cavities

- Rapid Turnaround | ISO 9001 Certified | NDA Protection

Precision 5-Axis CNC Machining Services

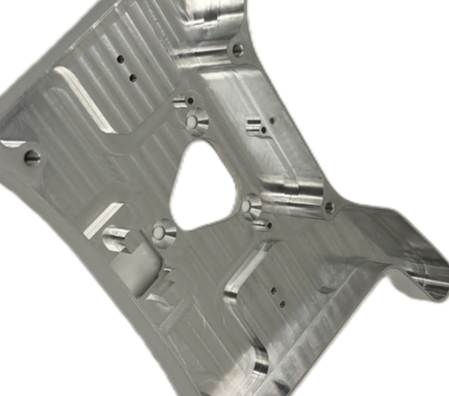

For industries demanding ultra-precise, complex components, Samshion’s 5-axis CNC machining provides unmatched flexibility and accuracy. By simultaneously moving across five axes, we produce intricate geometries, smooth surface finishes, and tight tolerances in a single setup — saving time and reducing costs.

Whether you need functional prototypes or high-volume production, we turn your most challenging designs into reality with micron-level precision.

What is 5-Axis Machining? | Samshion Precision Manufacturing

5-Axis vs. 3-Axis Machining: Which is Right for You?

In CNC machining, selecting between 3-axis and 5-axis systems directly impacts production quality, efficiency, and cost. At Samshion, we specialize in advanced manufacturing solutions tailored to meet diverse industrial needs.

3-Axis Machining:

Operates along X, Y, and Z linear axes, ideal for simpler parts with flat or mildly contoured surfaces.

Cost-effective for industries like automotive prototyping, consumer electronics, and basic tooling.

Limited to single-angle setups, requiring manual repositioning for complex geometries.

5-Axis Machining:

Adds two rotational axes (A and B), enabling the cutting tool to approach workpieces from virtually any angle.

Perfect for highly intricate parts with complex curves, undercuts, and tight tolerances (±0.001″).

Reduces setup time, minimizes human error, and boosts efficiency—ideal for aerospace components, medical implants, and luxury automotive parts.

At Samshion, we specialize in tailored CNC solutions to fit your project’s complexity, lead time, and cost goals.

Why Leading Brands Trust Samshion for 5-Axis CNC Machining?

At Samshion, we don’t just machine parts — we solve your most complex manufacturing challenges with precision, efficiency, and scale.

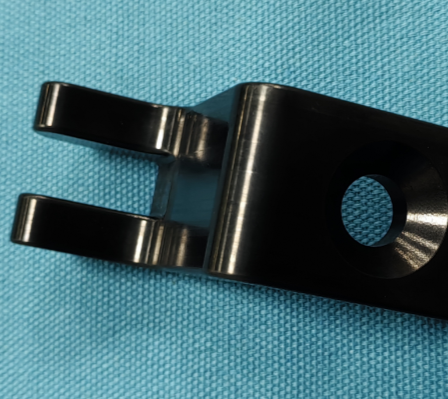

- Complex Geometries, Zero Hassle:

Easily handle intricate 3D contours, deep cavities, and organic designs in a single setup. Ideal for turbine blades, surgical instruments, and precision molds.

- Precision You Can Rely On:

ISO-certified processes ensure micron-level accuracy and flawless finishes. Fewer post-processing steps, faster delivery.

- Scalable & Cost-Efficient:

From prototypes to mass production, we optimize cycles, reduce material waste, and minimize setup time — keeping your costs down without sacrificing quality.

Samshion 5-Axis CNC Machine Shop

Advanced Technology, Unmatched Capabilities

We operate a cutting-edge fleet of 10+ state-of-the-art 5-axis CNC machines, including both horizontal and vertical machining centers, to deliver precision, speed, and scalability. Our robust infrastructure enables large-volume production without compromising on accuracy, making us the trusted partner for industries demanding perfection.

Material Versatility That Matches Your Project's Demands

Our state-of-the-art 5-axis CNC machining services support a vast range of industrial-grade materials, ensuring your custom parts meet exact performance, durability, and aesthetic requirements. From high-strength metals to engineering plastics, we offer over 50+ certified materials to match your application’s unique demands.

Metal

Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper, Magnesium Alloy, Titanium Alloy, Zinc Alloy.etc.

Plastic

ABS, PC, ABS+PC, PMMA(Acrylic), PA(Nylon), PA+GF30, POM(Acetal / Delrin), PP, PVC, HDPE, PPS, PEEK, PEI(Ultem), Teflon, Bakelite Resin, Epoxy Tooling Board.etc.

Description:

Aluminum alloys are engineered metallic materials composed primarily of aluminum combined with elements such as copper, magnesium, silicon, or zinc. Renowned for their exceptional strength-to-weight ratio, corrosion resistance, and versatility, aluminum alloys are widely used across industries ranging from aerospace to consumer electronics.

Alloys:

6061-T6, 7075-T6, 7050, 2024, 2A12,6082,5083,5052, 6063, MIC6.etc.

Finishing Options:

Alodine, Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing.

Description:

Stainless steel is a corrosion-resistant iron-based alloy containing a minimum of 10.5% chromium, combined with elements like nickel, molybdenum, and carbon. Renowned for its durability, aesthetic versatility, and hygienic properties, stainless steel is a cornerstone material in industries ranging from medical devices to architectural design.

Alloys:

303, 304L, 316L, 410, 416, 440C, 17-4PH, Nitronic 60.etc.

Finishing Options:

Electropolishing, ENP, Media Blasting, Nickel Plating, Passivation, Powder Coating, Tumble Polishing, Black Oxide, Zinc Plating, Vibratory Tumbling.

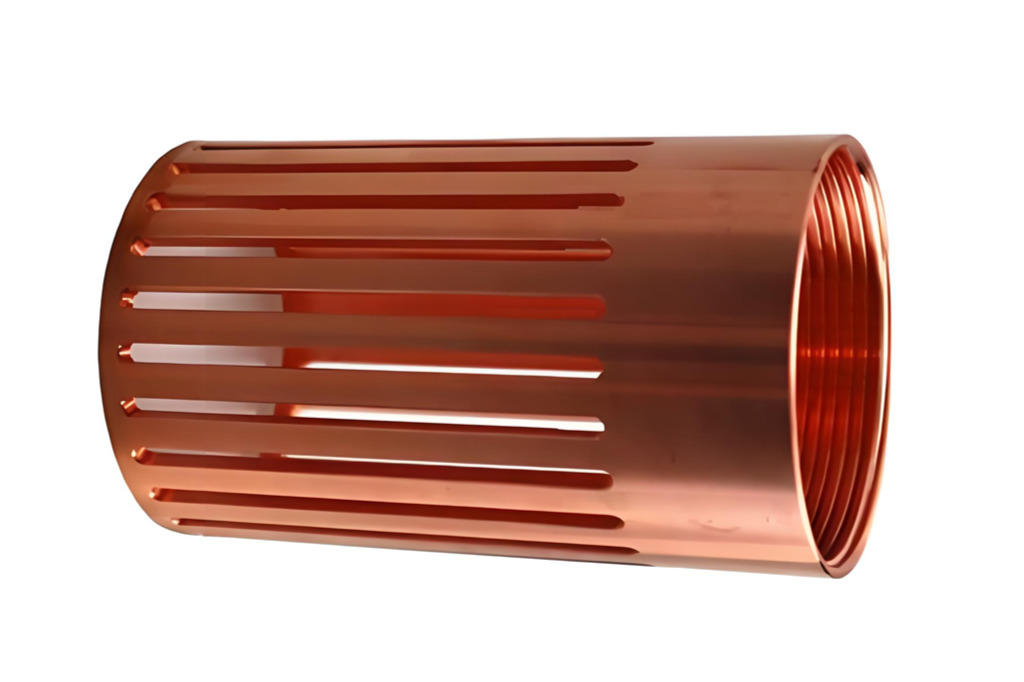

Description:

Copper, a ductile and malleable metal with exceptional electrical and thermal conductivity, is a cornerstone of modern technology and industrial applications. Known for its natural reddish-brown hue, corrosion resistance, and recyclability, copper and its alloys are indispensable in sectors ranging from electronics to renewable energy.

Alloys:

C1100,C1011.etc.

Finishing Options:

Media Blasting, Nickel Plating, Passivation, Tumble Polishing, Vibratory Tumbling.etc.

Description:

Brass alloys are versatile metallic materials primarily composed of copper and zinc, often enhanced with elements like lead, tin, or aluminum. Known for their excellent machinability, corrosion resistance, and aesthetic appeal, brass alloys are widely utilized in industries such as plumbing, musical instruments, decorative hardware, and electrical components.

Alloys:

C260, C360, C464, C485, C280, C220, C230, C510, C544, C675.

Finishing Options:

Polishing, Electroplating (Nickel, Chrome), Clear Lacquering, Antiquing, Powder Coating, Passivation, Sandblasting, Brushed Finish, Hot-Dip Galvanizing, Laser Etching.

Description:

Steel alloys are engineered metallic materials primarily composed of iron and carbon, often enhanced with elements like chromium, nickel, or molybdenum. Renowned for their exceptional strength, durability, and resistance to wear and corrosion, steel alloys are extensively used in industries such as construction, automotive manufacturing, industrial machinery, and tooling.

Alloys:

1045 Carbon Steel, A36 Mild Steel, 4140 Chromoly Steel, 4340 High-Strength Steel, D2 Tool Steel, A2 Tool Steel, 52100 Bearing Steel, 8620 Case-Hardening Steel.

Finishing Options:

Heat Treatment (Quenching, Tempering), Galvanizing, Powder Coating, Electroplating (Nickel, Chrome), Media Blasting, Passivation, Polishing, Black Oxide Coating, Anodizing, Laser Engraving.

Description:

Titanium alloys are advanced metallic materials primarily composed of titanium blended with elements like aluminum, vanadium, or nickel. Renowned for their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, titanium alloys are critical in high-performance industries such as aerospace, medical implants, marine engineering, and chemical processing.

Alloys:

Ti-6Al-4V (Grade 5), Ti-3Al-2.5V (Grade 9)

Finishing Options:

Anodizing (Type II, III), Media Blasting, Electropolishing, Passivation, Thermal Oxidation, PVD Coating, Laser Marking, Chemical Etching, Powder Coating, Grinding/Polishing.

Description:

Magnesium alloys are lightweight metallic materials primarily composed of magnesium combined with elements such as aluminum, zinc, or manganese. Renowned for their exceptional strength-to-weight ratio, vibration damping properties, and machinability, magnesium alloys are widely utilized in high-performance industries including aerospace, automotive lightweighting, consumer electronics, and biomedical devices.

Alloys:

AZ31B, AZ91D,

Finishing Options:

Anodizing (Type I, II), Chemical Conversion Coating (Chromate, Phosphate), Electroplating (Nickel, Copper), Powder Coating, Laser Etching, Passivation, Polishing, PVD Coating, Epoxy Sealing, Thermal Spraying.

Description:

ABS (Acrylonitrile Butadiene Styrene) is a versatile thermoplastic polymer celebrated for its excellent impact resistance, thermal stability, and ease of processing. Combining rigidity, surface gloss, and electrical insulation properties, ABS is extensively utilized in automotive parts, consumer electronics, household appliances, toys, and industrial piping systems.

Colors:

Opaque beige, Black.

Finishing Options:

As machined, Media blasting, Polishing, Painting, Texture coating, Clear lacquering, Electroplating

Description:

POM (Polyoxymethylene) is a high-performance engineering thermoplastic renowned for its exceptional mechanical strength, low friction coefficient, superior dimensional stability, and resistance to chemicals. With outstanding wear resistance and anti-creep properties, POM is widely used in precision mechanical components, gears, bearings, electronic connectors, medical devices, and automotive systems.

Colors:

White, Black.

Finishing Options:

As machined, Media blasting, Polishing,

Description:

Nylon is thermoplastic with high strength, wear resistance, excellent sound/vibration dampening, and low friction coefficient. It is commonly used in engineering and manufacturing processes. Common applications include gears, bearings, and bushings. Two of the most notable use cases for Nylon are in medical devices and electronics insulation, notably screws and spacers for panel mounted circuit boards.

Colors:

Opaque beige, Black.

Finishing Options:

As machined, Media blasting, Polishing,

Description:

PEEK, (polyether ether ketone) is a thermoplastic widely used in industries such as aerospace, automotive, and electronics. PEEK has high strength, stiffness, toughness, chemical, biocompatibility, and thermal resistance. Due to its , PEEK is also suitable for use in harsh environments where other materials may fail. Common applications include aircraft structures, electronic components that require high temperature resistance, and medical and dental components (including implantables).

Colors:

Opaque beige

Finishing Options:

As machined, Media blasting, Polishing,

Description:

PE is flexible, chemical-resistant, and impact-resistant.

Lightweight and cost-effective, this material is ideal for packaging, containers, and piping systems where durability and adaptability are essential.

Color:

Natural White,Black,

Finishing Options:

As machined, Sand blasting, Tumbling,

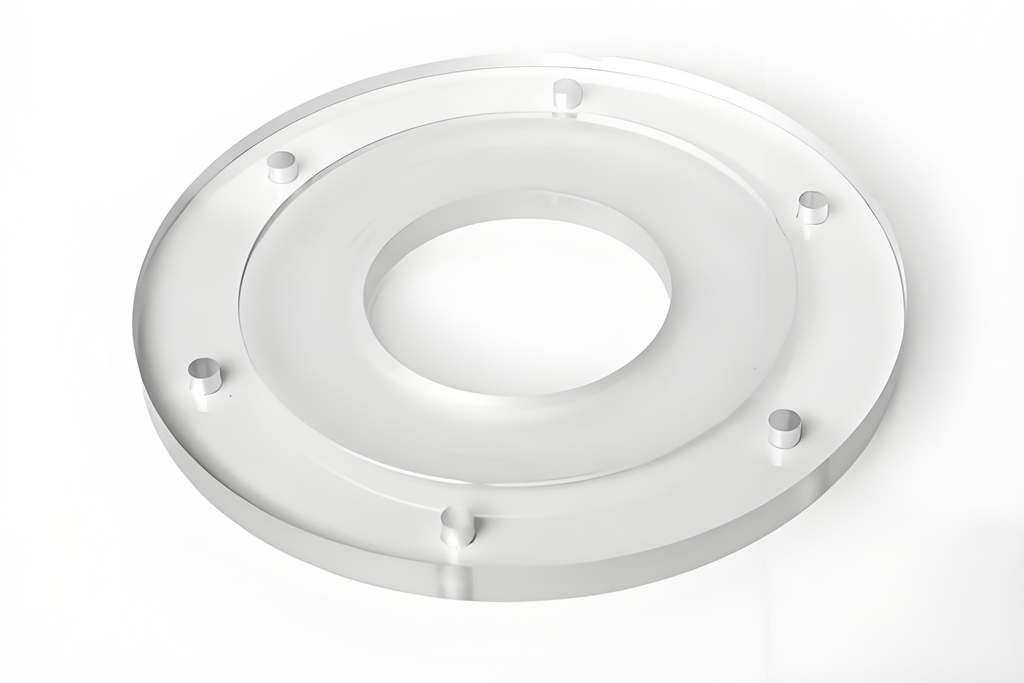

Description:

Polycarbonate (PC) is renowned for its exceptional clarity, high impact resistance, and thermal stability. Widely used in optical lenses, automotive components, and protective equipment, PC maintains structural integrity under stress while offering lightweight versatility.

Color:

Transparent,Black,

Finishing Options:

As machined, Media Blasting, Polishing, Anti-Scratch Coating, Painting, Textured Finish, Laser Etching

Description:

HIPS is lightweight, impact-resistant, and easy to machine.

Ideal for prototyping and consumer products, this material balances durability and cost-effectiveness while offering excellent surface finish for aesthetic applications.

Color:

Natural White,Black,

Finishing Options:

As machined, Media blasting, Polishing, Painting, Texture coating, Clear lacquering, Electroplating

Elevate Your Parts with Premium Surface Finishes

Surface Finishes for 5-Axis CNC Machining

We transform 5-axis CNC machined components into high-performance, visually stunning products through our advanced surface finishing solutions. Our finishes enhance durability, corrosion resistance, surface roughness, and aesthetics, while eliminating tool marks and imperfections. Whether your project demands functional resilience or flawless visuals, Samshion delivers tailored finishes to exceed expectations.

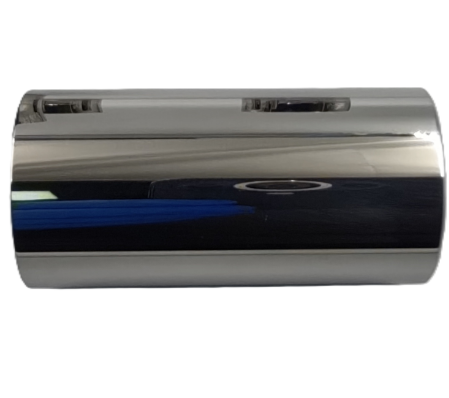

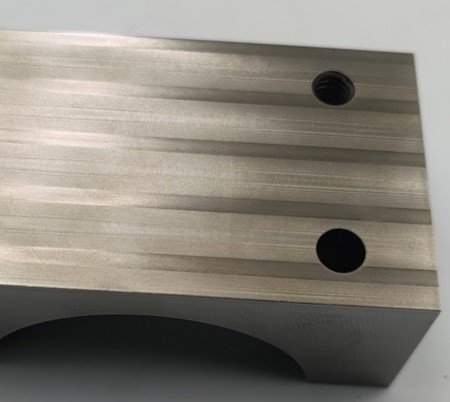

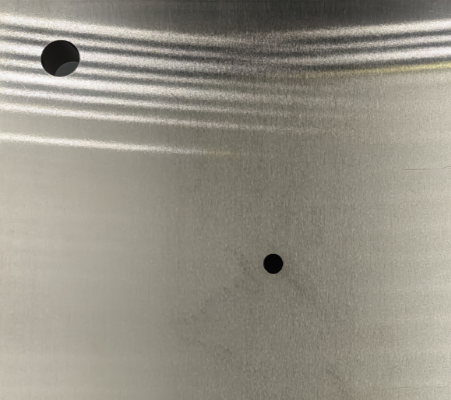

As Machined

The as-machined finish delivers parts directly from CNC machining, retaining minor tool marks for a cost-effective solution. Ideal for functional prototypes and non-critical components requiring no post-processing.

Anodizing

Anodizing enhances corrosion resistance, wear resistance, and aesthetics for aluminum parts. Custom colors and glossy finishes available.

Polishing

Achieve a mirror-like finish with polishing, reducing surface roughness to Ra 0.2 µm. Perfect for luxury products and optical components.

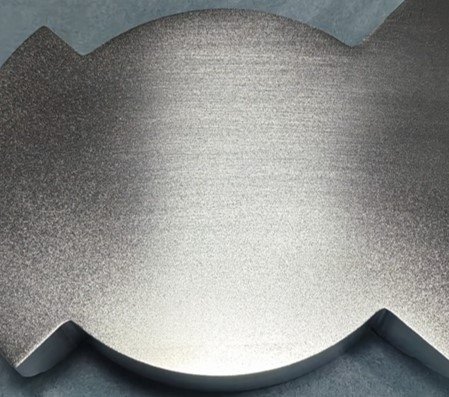

Sand Blasting

Sand blasting creates a uniform matte texture, hiding imperfections and improving paint adhesion. Uses pressurized media for consistent results.

Tumbling

Tumbling smooths edges and surfaces via friction in a rotating barrel, offering a slightly textured, uniform finish for small parts.

Electropolishing

Electropolishing chemically removes surface layers to enhance smoothness, brightness, and corrosion resistance. Ideal for stainless steel and medical devices.

Alodine

Alodine coating provides corrosion protection and paint adhesion for aluminum, with a conductive yellow film.

Heat Treatment

Heat treatment enhances metal properties like hardness, strength, or ductility in a controlled vacuum environment.

Brushed Finish

A brushed finish creates a unidirectional satin texture, masking scratches and adding aesthetic appeal.

Powder Coating

Powder coating applies a thick, wear-resistant polymer layer with vibrant color options and UV resistance.

Nickel Electroplating

Electroplating deposits a thin nickel layer for enhanced wear resistance, conductivity, and corrosion protection.

Black Oxide Coating

Black oxide forms a magnetite layer on ferrous metals, reducing glare and improving corrosion resistance.

Precision Engineered for Excellence

5-Axis CNC Machining Capabilities

Our ISO 9001-certified 5-axis CNC machining services deliver unmatched accuracy, meeting the tightest tolerances for industries demanding perfection. Whether prototyping or mass production, we ensure high-quality, dimensionally stable parts with superior surface finishes and structural integrity.

Technical Specifications

Explore our advanced machining capabilities designed to handle complex geometries and critical applications:

| Parameter | Capability |

|---|---|

| Maximum Part Size | 1000 × 1000 × 600 mm |

| Minimum Part Size | 5 × 5 × 5 mm |

| Standard Tolerances | ±0.002 mm (metals & plastics) |

| Lead Time | 2-3 days (standard) |

| Up to 2 weeks (complex projects) |

Optimize Your Designs for Precision & Efficiency

5-Axis CNC Machining Design Guidelines

We empower engineers and designers to create flawless, manufacturable components with our expert 5-axis CNC machining design guidelines. Follow these recommendations to ensure structural integrity, accuracy, and cost-effective production for complex geometries.

Key Design Specifications

Adhere to these critical parameters to maximize machining success:

| Design Feature | Recommendation |

|---|---|

| Minimum Feature Size | 0.5 mm (width/depth) to maintain structural integrity and tool accessibility. |

| Linear Dimensions | Tolerance within ±0.005 mm for critical dimensions. |

| Hole Diameters | Standard range: 1 mm to 40 mm (non-reamed). Specify tolerances for precision. |

| Shaft Diameters | 2 mm to 300 mm (ensure tool clearance and torque compatibility). |

| Threads & Tapped Holes | M2 to M24 threads with adequate bottom relief for tapping tools. |

| Engraved Text | Minimum 1.5 mm height and 0.5 mm depth for legibility post-machining. |

Choosing the Right 5-Axis Machining Strategy

Simultaneous 5-Axis vs. 3+2-Axis CNC Machining

We leverage advanced 5-axis CNC technologies to optimize precision, efficiency, and cost-effectiveness. Understand the differences between simultaneous 5-axis and 3+2-axis machining to select the ideal solution for your project.

Simultaneous 5-Axis Machining

Continuous Multi-Axis Movement:

All 5 axes (X, Y, Z, A, B) move simultaneously, enabling seamless transitions and superior surface finishes.

Ideal for complex contours, organic shapes, and aerospace components requiring uninterrupted tool paths.

3+2-Axis Machining

Fixed-Angle Efficiency:

The workpiece is locked at a specific angle, allowing 3-axis tool movement with the added flexibility of two rotational axes.

Perfect for milling deep cavities, undercuts, and parts requiring multiple setups.

Trunnion-Style Machining Centers

Fixed Table, Moving Spindle:

The spindle rotates along A and B axes, while the table remains stationary.

Best for heavy, large workpieces (e.g., aerospace frames, automotive molds) requiring stable support.

Swivel-Rotate-Style Machining Centers

Rotating Table, Fixed Spindle:

The table tilts and rotates (C and A axes), offering superior access to intricate features.

Ideal for small, delicate components (e.g., medical instruments, micro-electronics) needing multi-angle precision.

Unlock Precision & Efficiency with 5-Axis CNC Machining

Key Advantages of 5-Axis CNC Machining

5-axis CNC machining revolutionizes manufacturing by combining speed, accuracy, and versatility. At Samshion, we leverage this technology to deliver superior results for industries demanding perfection.

- Complex Geometries Made Simple: Machine intricate 3D contours, undercuts, and organic shapes in a single setup, eliminating manual repositioning.

- Enhanced Accuracy & Repeatability: Achieve ±0.002 mm tolerances with minimal human intervention, reducing errors from multiple setups.

- Superior Surface Finishes: Maintain optimal tool angles for mirror-like finishes (Ra ≤ 0.4 µm), reducing post-processing costs.

- Shorter Tools, Better Stability: Reduce tool deflection and vibration with compact cutting tools, ensuring precision in deep cavities.

- Faster Production Cycles: Slash lead times by 50%+ through simultaneous multi-axis machining.

- Material Efficiency: Optimize tool paths to minimize waste, especially with costly alloys like titanium and PEEK.

Industry Applications of 5-Axis CNC Machining

Samshion’s 5-axis solutions empower innovation across sectors requiring precision and complexity:

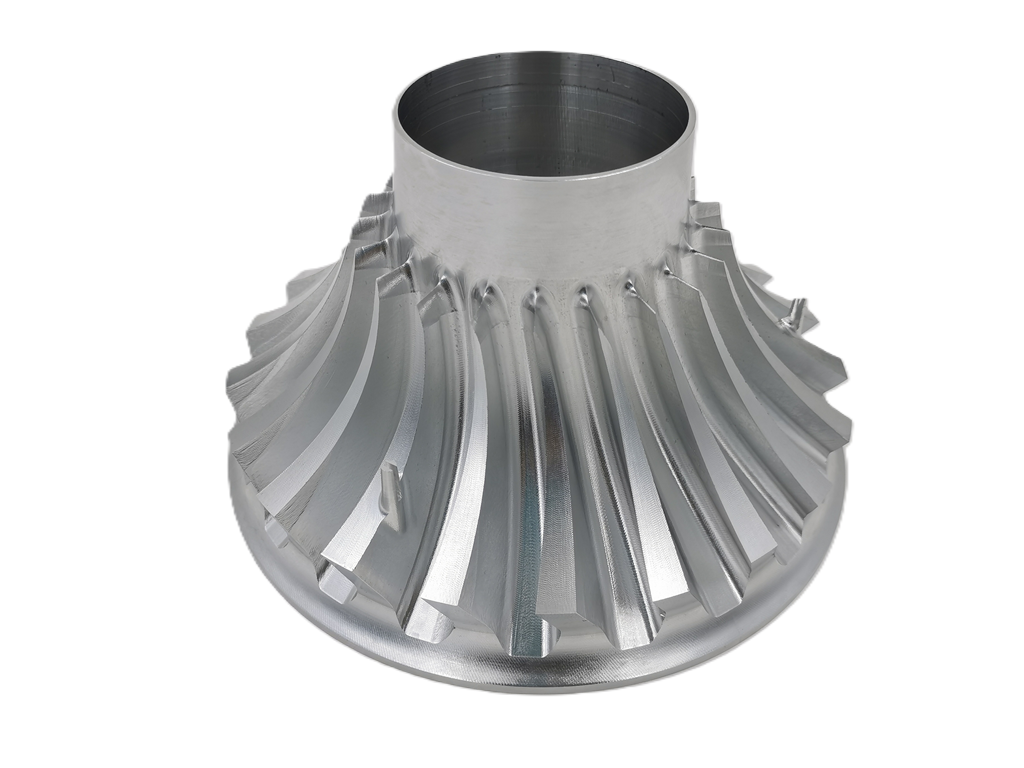

- Aerospace & Defense: Turbine blades, engine mounts, UAV components – withstanding extreme temperatures and stress.

- Automotive Engineering: EV battery housings, transmission gears, lightweight chassis – balancing strength and efficiency.

- Medical Technology: Patient-specific implants, surgical robots, MRI-compatible devices – biocompatible and ultra-smooth.

- Energy & Renewable Systems: Wind turbine hubs, solar panel frames, hydraulic valves – engineered for longevity and reliability.

- Marine & Heavy Machinery: Propellers, pump housings, corrosion-resistant hull parts – built to endure harsh environments.

- Consumer Electronics: Heat sinks, micro-connectors, wear-resistant enclosures – precision-machined for peak performance.

5-Axis CNC Machining FAQs

Can 5-axis machining provide tight tolerances?

Yes! At Samshion, our 5-axis CNC machines achieve tolerances as tight as ±0.002 mm (0.0008″), making them ideal for aerospace, medical, and automotive components requiring extreme precision.

How much does your 5-axis milling service cost?

Costs vary based on material, part complexity, and volume. However, 5-axis machining often reduces total expenses by minimizing setups and secondary operations. Contact us for a free quote tailored to your project.

When should I choose 5-axis CNC machining?

Complex geometries (undercuts, 3D contours, deep cavities).

Multi-angle features requiring simultaneous tool movement.

High-tolerance demands (±0.005 mm or tighter).

Common applications include turbine blades, medical implants, and automotive prototypes.

What’s the difference between 5-axis and 3-axis machining?

3-Axis: Cuts along X, Y, Z axes—ideal for flat or mildly contoured parts.

5-Axis: Adds A and B rotational axes, enabling multi-angle machining in a single setup.

Samshion’s 5-axis technology reduces cycle times, improves accuracy, and handles complex designs unachievable with 3-axis.

What is 5-axis CNC machining?

5-axis CNC machining allows tools to move along five axes (X, Y, Z, A, B) simultaneously, creating intricate geometries with unmatched precision. At Samshion, we use this technology for aerospace components, surgical tools, and EV battery housings.

How does a 5-axis CNC machine work?

Simultaneous movement: The tool and workpiece rotate/tilt dynamically for multi-angle access.

Single setup: Eliminates repositioning errors, ensuring ±0.002 mm tolerances.

Advanced CAM software: Generates collision-free tool paths for flawless finishes.