Rapid Tooling Services | Accelerate Prototyping And Market Testing

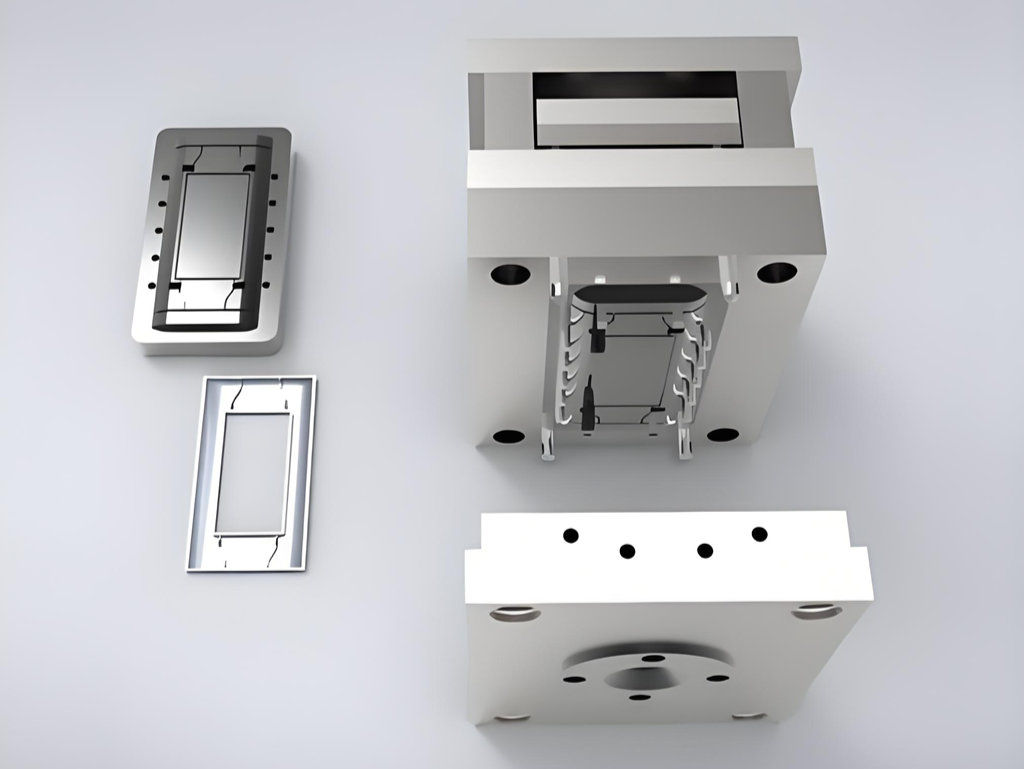

When time-to-market is critical, rapid tooling bridges the gap between design validation and low-volume production. Our solutions enable Rapid Tooling Services and injection molding, delivering functional parts in days—not weeks—so you can test product viability, refine designs, and gauge market response with minimal risk.

Precision Rapid Tooling Solutions for Prototypes & Low-Volume Production

At Samshion, we leverage cutting-edge technology, engineering expertise, and customer-centric collaboration to deliver high-quality rapid tooling services for prototypes and short-run manufacturing. Our team partners closely with clients to craft tailored solutions that balance speed, cost, and precision—ensuring your project transitions seamlessly from concept to production.

Rapid Tooling Services

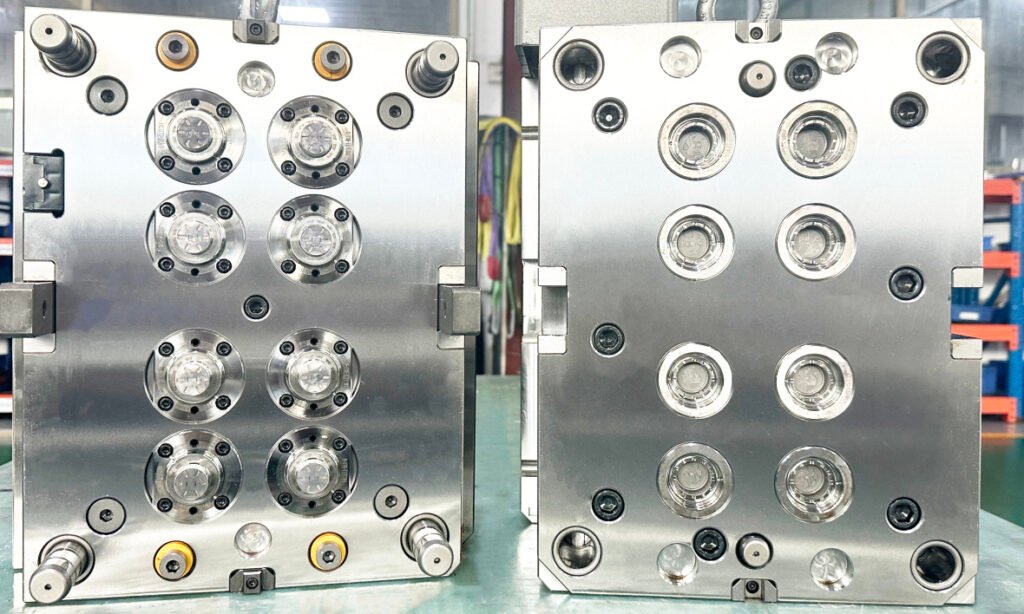

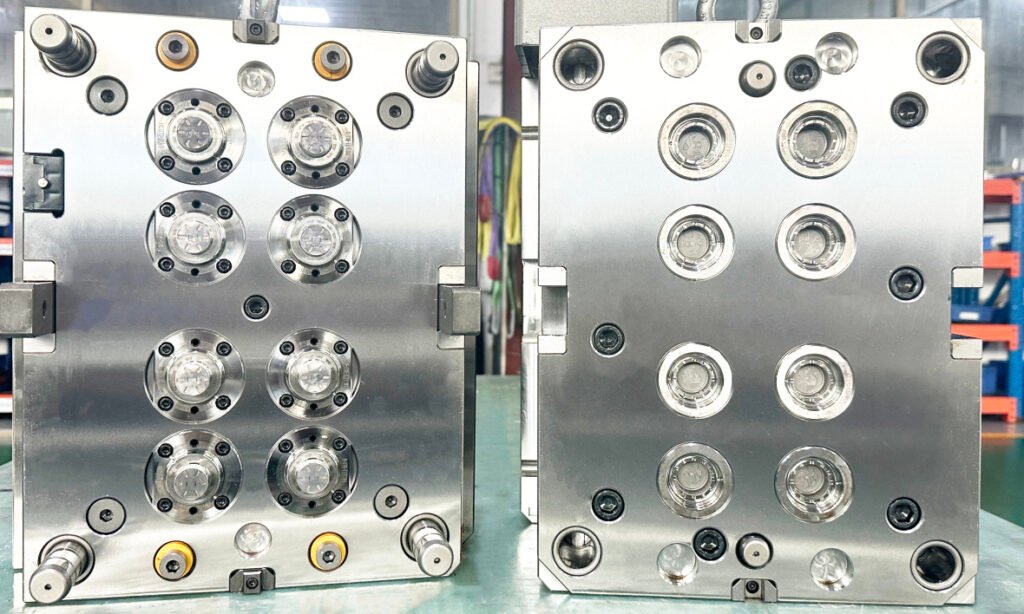

Accelerate your timeline with machined aluminum or mild steel molds designed for low-volume injection molding. Simplified designs, pre-engineered mold bases, and standardized components reduce lead times while maintaining durability for repeated cycles.

- Aluminum/steel molds for 100–10,000+ parts

- Streamlined design for faster turnaround

- Cost-effective tooling for iterative testing

Rapid Injection Molding

Execute small-batch production or functional prototyping with our dedicated fleet of injection molding machines. Molds are prioritized for immediate machine loading, minimizing downtime and ensuring rapid part delivery.

- On-demand runs for 50–5,000 units

- 15+ molding machines for flexible material options

- Tight tolerances (±0.1mm) and smooth finishes

Fast, Cost-Efficient Prototyping Solutions

What is Rapid Tooling?

Rapid tooling (also called prototype tooling or bridge tooling) is a streamlined method for producing low-volume injection-molded plastic parts quickly and affordably. By creating durable aluminum or mild steel molds, this process enables the production of functional prototypes or small batches—ideal for bridging the gap between design validation and high-volume manufacturing.

How Rapid Tooling Works

The process involves machining molds from aluminum or soft steel, combined with pre-fabricated mold bases and manual inserts. Unlike traditional tooling, which is costly for small projects, rapid tooling prioritizes speed and cost-efficiency for short-run production.

- Materials: Aluminum (for 100–5,000 cycles) or steel (for higher durability).

- Output: 50–10,000+ parts per mold, depending on material and design.

- Methods: CNC machining, EDM, or hybrid additive techniques like 3D-printed inserts.

Precision Manufacturing Solutions | Quality, Speed, Expertise

Why Choose us for Rapid Tooling?

High-Precision Components

Deliver flawlessly engineered parts with tolerances as tight as ±0.02mm. Our advanced quality systems and CNC-driven processes ensure dimensional accuracy and consistency, whether for prototypes or production runs.

- Micron-level precision for critical applications

- Material versatility: plastics, metals, and composites

- Surface finishes from textured to medical-grade polished

Fast-Track Production

Leverage our streamlined supply chain and in-house manufacturing facilities to slash lead times. From mold design to final parts, we prioritize agility without compromising quality—ideal for urgent prototyping or low-volume batches.

- Rapid tooling in 5–10 business days

- Low-volume runs shipped in 2–3 weeks

- Scalable solutions for seamless ramp-up

Engineering Support

Our team of engineers and designers partners with you to optimize manufacturability, reduce costs, and solve complex challenges. From DFM feedback to material selection, we ensure your project stays on track.

- Design-for-manufacturing (DFM) analysis

- Material and process optimization

- Post-processing and assembly guidance

Advantages of Rapid Tooling

Accelerated Timelines

Rapid tooling slashes production lead times, enabling seamless transitions from prototyping to low-volume manufacturing. Achieve functional parts in days—not weeks—to meet tight deadlines.

Ready to Harness Rapid Tooling Benefits?

Cost-Effective Scaling

Optimize budgets for orders of 100–5,000 units. Avoid overinvestment in mass-production molds or costly alternatives like CNC machining for mid-sized batches.

Broad Material Compatibility

Leverage the same material options as traditional injection molding—from ABS and nylon to engineering-grade polymers—ensuring performance aligns with final product requirements.

Custom Surface Finishes

Tailor part aesthetics with molds designed for smooth, textured, or glossy finishes. Post-processing options like painting, plating, or laser etching add further customization.

Budget-Friendly Solutions

Reduce upfront tooling costs by up to 70% compared to hardened steel molds, maximizing ROI for small-to-medium production runs.

Design Validation & Iteration

Test functionality, durability, and user ergonomics with real-world prototypes. Implement design tweaks swiftly through modular mold adjustments.

Faster Market Entry

Compress development cycles and launch products ahead of competitors. Rapid tooling ensures speed without sacrificing quality or precision.

Production Parts and Prototypes Manufacturing Case Study Showcase

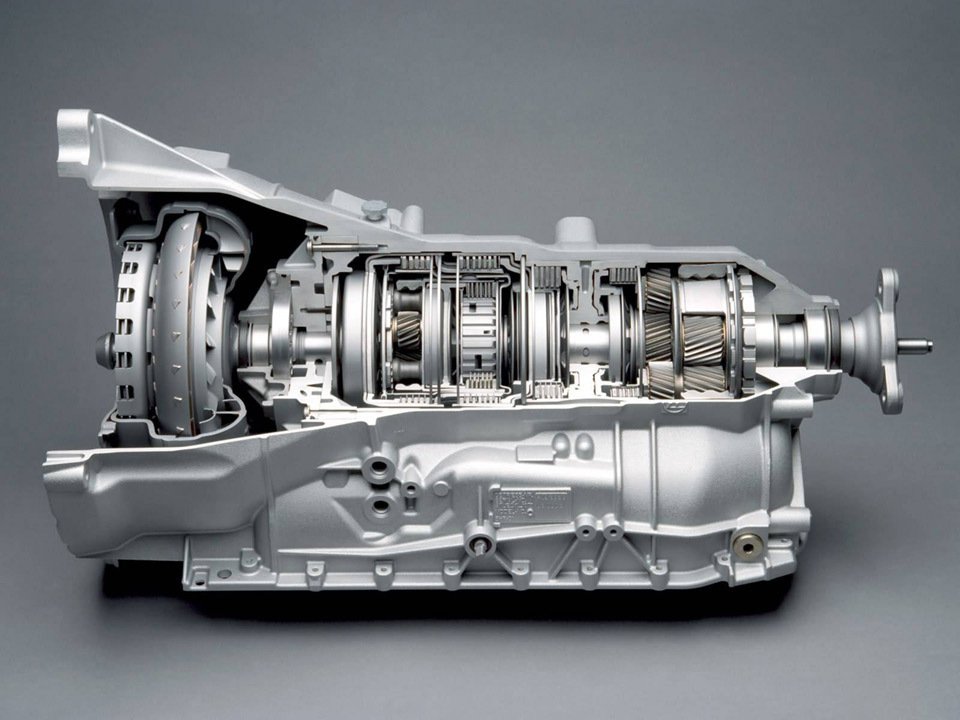

From aerospace components requiring micron-level tolerances to medical device prototypes demanding biocompatible precision, Samshion’s ISO-certified manufacturing ecosystem transforms complex challenges into market-ready solutions. Explore how intelligent quality systems have empowered: